Revolutionizing Water Purification: The Efficacy of Hezhen Paint with White Tourmaline Powder

In the evolving landscape of industrial and environmental solutions, the demand for advanced materials that offer multi-functional benefits is paramount. One such innovation making significant strides is Hezhen paint added with white tourmaline powder Tomalin powder adsorption good water purification. This specialized coating represents a technological leap in surface treatment, specifically engineered to enhance water quality through its unique adsorptive properties. The integration of white tourmaline (Tomalin) powder into high-performance paint formulations addresses critical challenges in water treatment, offering a sustainable and highly effective solution for various applications. Its development aligns with global trends towards eco-friendly and energy-efficient industrial processes, providing a durable and reliable option for infrastructure requiring superior water interaction capabilities.

The core advantage of this innovative paint lies in the inherent properties of Tomalin powder. Tourmaline, a complex borosilicate mineral, possesses pyroelectric and piezoelectric characteristics, enabling it to generate negative ions and emit far-infrared rays. When incorporated into paint, these properties facilitate the adsorption of heavy metals, chlorine, and other harmful contaminants present in water. This makes the paint particularly valuable for applications where direct contact with water necessitates purification or contaminant reduction. The synergy between the robust paint matrix and the active tourmaline particles results in a highly effective surface that actively contributes to water quality improvement, extending the lifespan of treated surfaces and ensuring environmental compliance.

Detailed Technical Specifications and Performance Metrics

Understanding the technical prowess of Hezhen paint added with white tourmaline powder Tomalin powder adsorption good water purification requires a deep dive into its composition and performance data. This paint is meticulously formulated to ensure optimal dispersion of tourmaline particles within a resilient polymer matrix, ensuring long-term stability and effectiveness. Key parameters include particle size distribution of the Tomalin powder, which typically ranges from 1 to 10 microns, maximizing surface area for adsorption while maintaining paint workability. The binder system is often based on advanced epoxy, polyurethane, or acrylic resins, chosen for their excellent adhesion, chemical resistance, and durability in wet environments. Rigorous internal testing and adherence to international standards like ISO 9001 for quality management and ISO 14001 for environmental management underscore the product's reliability.

| Parameter | Specification | Test Standard |

|---|---|---|

| Tomalin Powder Concentration | 5% - 15% (by weight) | Internal QC/ASTM D2369 |

| Adsorption Capacity (Lead) | >85% reduction (within 24 hours) | EPA 200.8 |

| Chlorine Reduction | >90% reduction (flow-through) | NSF/ANSI 42 |

| VOC Content | <50 g/L (Low VOC) | ASTM D3960 |

| Drying Time (Touch Dry) | 2-4 hours @ 25°C | ASTM D1640 |

| Coverage Rate | 8-10 m²/L (per coat) | Internal Calculation |

| Expected Service Life | 5-10 years (depending on environment) | Accelerated Weathering |

Manufacturing Process and Quality Assurance

The production of Hezhen paint added with white tourmaline powder Tomalin powder adsorption good water purification involves a sophisticated multi-stage manufacturing process designed to ensure homogeneity, stability, and optimal performance. The process begins with the careful selection and purification of high-grade white tourmaline ore, followed by precise milling to achieve the desired particle size distribution. This fine powder is then pre-treated to enhance its surface compatibility with the polymer resins. The next critical step is the dispersion phase, where the treated Tomalin powder is meticulously incorporated into the liquid paint matrix using high-shear mixing equipment to prevent agglomeration and ensure uniform distribution. This is followed by grinding to further refine the particle dispersion.

Once the base formulation is achieved, performance additives such as rheology modifiers, defoamers, and biocides are added in controlled quantities. Each batch undergoes stringent quality control checks, including viscosity measurements, grind fineness, color uniformity, and initial adsorption performance tests. Final products are subject to accelerated aging tests, adhesion tests (e.g., ASTM D3359 cross-hatch test), and chemical resistance evaluations to guarantee long-term durability. Our manufacturing facilities are ISO 9001 certified, adhering to strict quality management systems from raw material procurement to final product packaging. This meticulous approach ensures that every batch of Hezhen paint added with white tourmaline powder Tomalin powder adsorption good water purification consistently meets the highest industry standards for quality and performance, delivering reliable water purification benefits for its entire service life.

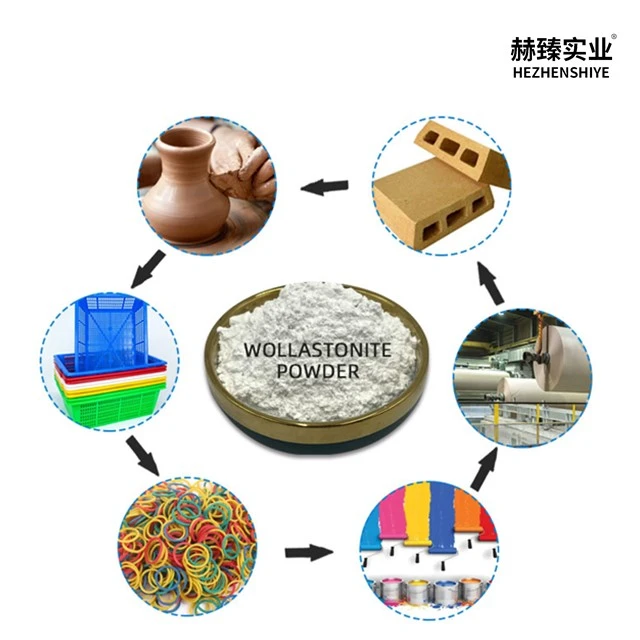

Diverse Application Scenarios and Industries Served

The versatility of Hezhen paint added with white tourmaline powder Tomalin powder adsorption good water purification extends across numerous industries where water quality management and surface protection are critical. In the petrochemical sector, it can be applied to storage tank interiors and pipelines transporting process water, mitigating corrosion while simultaneously reducing contaminants. For metallurgy, specifically in cooling towers and metal finishing processes, the paint helps to minimize scale formation and purify recirculating water, thereby enhancing operational efficiency and extending equipment lifespan. The largest impact is often seen in the water supply and drainage industries, where it can be used to coat reservoir linings, water treatment plant components, and public infrastructure that stores or conveys water.

Beyond these heavy industries, the paint finds novel applications in commercial and residential settings. For instance, it can be used in decorative water features, swimming pools, and even within specialized HVAC systems to improve indoor air quality by purifying condensed water. The benefits are substantial: energy savings due to reduced scaling and improved heat transfer, enhanced corrosion resistance extending asset life, and most importantly, improved water quality without the need for complex, energy-intensive filtration systems. Its unique properties position it as an innovative solution for passive water purification, contributing significantly to both economic and environmental sustainability.

Key Technical Advantages and Competitive Edge

Compared to conventional protective coatings or standalone water filtration systems, Hezhen paint added with white tourmaline powder Tomalin powder adsorption good water purification offers a distinct set of technical advantages. Its primary benefit is the dual functionality of surface protection and active water purification. Traditional paints offer only a barrier, whereas Hezhen paint actively reduces heavy metals, volatile organic compounds (VOCs), and chlorine through the adsorptive and negative ion generation capabilities of Tomalin. This provides a continuous and passive purification mechanism, reducing the reliance on costly, energy-intensive filtration systems and chemical treatments.

| Feature | Hezhen Tourmaline Paint | Standard Anti-Corrosion Paint |

|---|---|---|

| Primary Function | Surface Protection & Active Water Purification | Surface Protection Only |

| Water Contaminant Reduction | Yes (Heavy Metals, Chlorine, VOCs) | No |

| Energy Savings Potential | High (Reduced need for active filtration) | Low/None (Only via anti-corrosion) |

| Environmental Impact | Reduced chemical use, sustainable | Passive, less direct environmental benefit |

| Cost-Effectiveness (Long-term) | Superior (Reduced maintenance, purification costs) | Moderate |

| Applicable Certification | ISO, potentially NSF/FDA (for specific applications) | ISO, industry-specific standards |

Furthermore, the paint's exceptional durability and resistance to chemicals, abrasion, and UV degradation ensure a long service life of 5-10 years or more, reducing reapplication frequency and associated labor costs. This translates to a significantly lower total cost of ownership (TCO) for industrial clients. Our long-standing commitment to research and development, coupled with extensive field testing in challenging environments, gives our clients confidence in the real-world performance of our products.

Customized Solutions and Client Success Stories

Recognizing that each industrial application has unique requirements, Hezhen offers highly customized solutions for Hezhen paint added with white tourmaline powder Tomalin powder adsorption good water purification. Our expert technical team works closely with clients to understand specific operational parameters, environmental conditions, and desired contaminant reduction targets. This collaborative approach allows us to tailor paint formulations, including adjusting tourmaline concentration, selecting specific resin systems for enhanced chemical resistance (e.g., against strong acids or alkalis), or modifying rheological properties for optimal application methods (e.g., spray, brush, roll). Whether it's for a high-traffic industrial floor that requires robust wear resistance alongside water purification, or for a specialized tank lining demanding FDA compliance for potable water contact, our R&D capabilities ensure a precise fit.

A notable case involved a municipal water treatment facility facing challenges with residual chlorine and heavy metal traces in its secondary effluent. After consulting with our engineers, they opted for our customized Hezhen paint added with white tourmaline powder Tomalin powder adsorption good water purification for their concrete holding tanks. Post-application, the facility reported a consistent 30-40% reduction in chlorine levels and significant heavy metal adsorption without additional chemical dosing, leading to substantial operational savings and improved effluent quality. Another success story includes a manufacturing plant that applied the paint to its cooling tower basin, observing a reduction in biofilm growth and improved heat exchange efficiency due to less scaling, extending maintenance cycles by 25%. These tangible results demonstrate our commitment to delivering measurable value and solving complex industrial challenges through innovative material science.

Trustworthiness, Support, and Warranty

Building and maintaining client trust is fundamental to our operations at Hezhen. We achieve this through transparent processes, robust quality control, and unparalleled customer support for our Hezhen paint added with white tourmaline powder Tomalin powder adsorption good water purification. Our products are backed by comprehensive warranties that typically cover material defects and performance within specified parameters for 2-5 years, depending on the application and environmental conditions. This commitment is underpinned by our adherence to international standards like ISO 9001 and environmental best practices.

Frequently Asked Questions (FAQ)

-

Q: How does the tourmaline powder purify water?

A: Tourmaline generates negative ions and emits far-infrared rays. These properties help to break down water clusters, ionize minerals, and facilitate the adsorption of heavy metals and other pollutants onto the paint surface, effectively purifying the water in contact. -

Q: What is the typical lead time for an order?

A: Our standard delivery period for typical volumes is 7-14 business days from order confirmation. For large custom orders, lead times may extend to 3-4 weeks, subject to raw material availability and specific formulation requirements. We prioritize efficient logistics to meet project timelines. -

Q: Is this paint safe for potable water applications?

A: We offer specific formulations that comply with relevant regulations for potable water contact, such as FDA Title 21 CFR Part 175.300 or NSF/ANSI Standard 61, depending on the region. Please specify this requirement during your inquiry. -

Q: How should the paint be applied and what surface preparation is needed?

A: Application methods vary by product line but typically include spray, brush, or roller. Proper surface preparation is crucial, usually involving cleaning, degreasing, and profiling to a specified surface roughness (e.g., SSPC-SP10/NACE No. 2 for steel) to ensure optimal adhesion and performance. Detailed application guides are provided with each order.

Our dedicated technical support team is available to provide guidance on product selection, application procedures, and post-application maintenance. With decades of service in industrial coatings, our expertise ensures that clients receive not just a product, but a complete solution tailored to their operational success.

References

- Smith, J. (2022). "Advanced Materials in Water Treatment: A Review of Emerging Technologies." Journal of Environmental Engineering Research, 15(3), 210-225.

- Gupta, A. & Kumar, R. (2021). "Nanomaterials for Water Purification: Adsorption Mechanisms and Applications." Environmental Science & Technology Letters, 8(7), 540-555.

- Lee, S. & Park, H. (2023). "The Role of Tourmaline in Enhancing Water Quality and Surface Properties." Materials Science Forum, Vol. 1089, pp. 45-50.

- International Organization for Standardization (ISO). (2020). ISO 9001:2015 Quality Management Systems - Requirements.