Advancements in Water Treatment and Ceramic Coatings with Tourmaline Integration

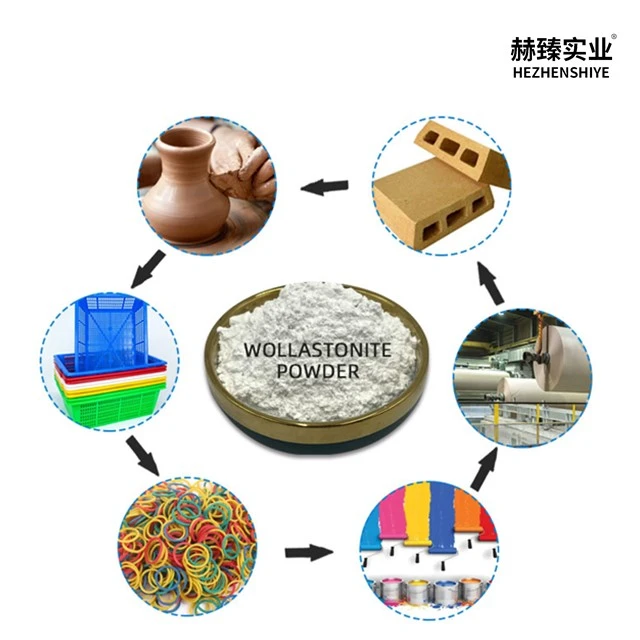

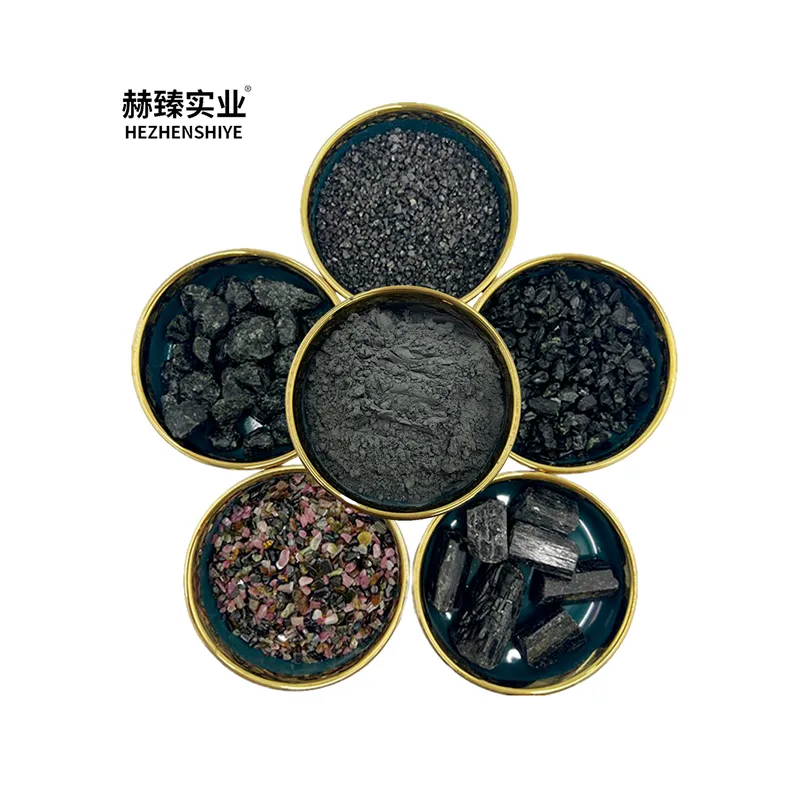

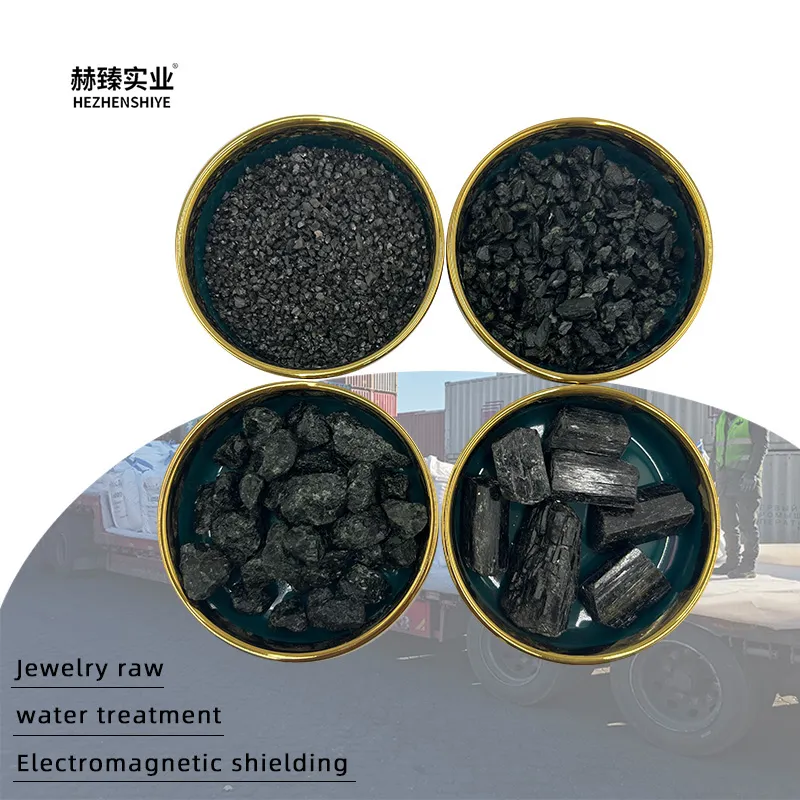

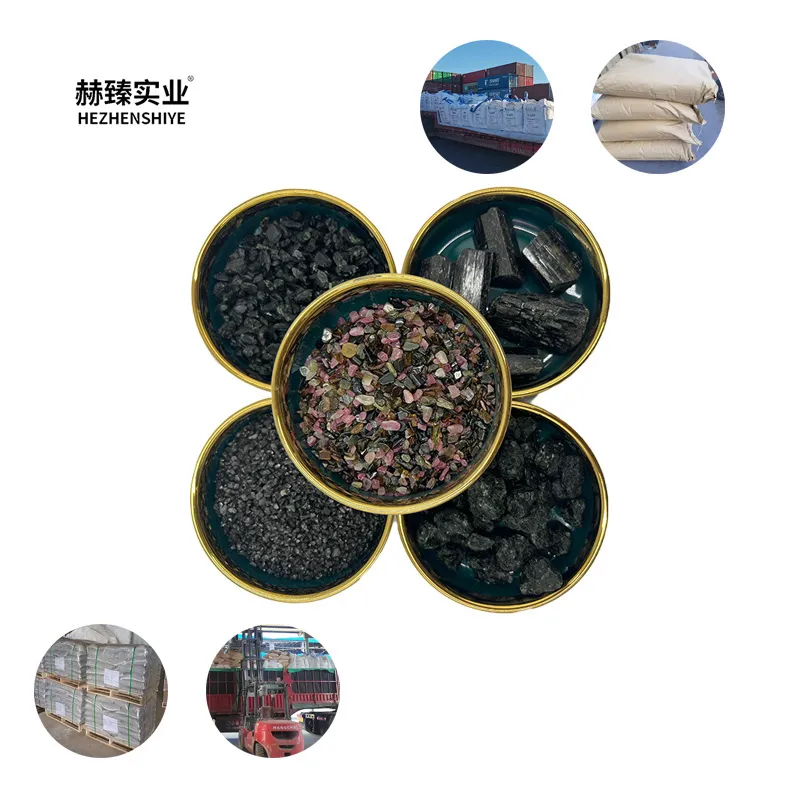

The global landscape of water treatment and advanced material science is undergoing significant transformation, driven by an escalating demand for sustainable, efficient, and cost-effective solutions. In the realm of industrial applications, particularly in sectors like petrochemical, metallurgy, and municipal water management, the integrity and performance of materials exposed to aggressive environments are paramount. Traditional approaches often grapple with issues such as biofouling, scale formation, and corrosion, leading to decreased operational efficiency, increased maintenance costs, and compromised system longevity. This necessitates innovative material compositions that can actively mitigate these challenges while promoting environmental responsibility. Emerging trends point towards the integration of functional minerals into advanced composite materials, offering enhanced physiochemical properties. Specifically, tourmaline, a complex borosilicate mineral, has garnered considerable attention for its pyroelectric and piezoelectric properties, which enable it to generate weak electric fields and emit far-infrared radiation. These characteristics are particularly advantageous for water activation and purification processes, as well as for developing robust, self-cleaning, and corrosion-resistant coatings. The market demand for solutions that extend equipment lifespan, reduce chemical consumption, and improve water quality is propelling research and development into sophisticated materials like specialized tourmaline-infused composites, signaling a shift towards proactive material engineering rather than reactive maintenance. Our focus here is on Hezhen Black tourmaline for water treatment of coating ceramics added with tourmaline powder, a solution at the forefront of this technological evolution, designed to address these complex industrial requirements by leveraging the unique attributes of black tourmaline. This material also functions as a refractory material with strong adsorbability, further enhancing its utility in diverse demanding applications where high temperatures and effective impurity removal are critical considerations.

Technical Specifications and Performance Parameters

The efficacy of materials such as Hezhen Black tourmaline for water treatment of coating ceramics added with tourmaline powder is quantified through rigorous technical specifications and performance parameters, which are critical for discerning their suitability across various industrial applications. Our black tourmaline is sourced from pristine geological deposits, ensuring a high purity level of over 98% and a consistent chemical composition predominantly consisting of complex borosilicates of aluminum with iron, magnesium, and other elements, which are crucial for its functional properties. The particle size distribution of the tourmaline powder, a critical determinant for its integration into ceramic matrices, typically ranges from 1 to 5 microns, enabling homogenous dispersion and optimal surface area exposure for water interaction. This precise control over particle morphology ensures maximum catalytic and adsorptive performance within the coating. Key physical properties include a Mohs hardness of 7-7.5, providing exceptional abrasion resistance, and a specific gravity of 3.0-3.2 g/cm³, indicating its density and structural integrity. For applications requiring a refractory material with strong adsorbability, its melting point exceeding 1200°C ensures stability in high-temperature environments, making it ideal for linings in furnaces or kilns. Furthermore, its zeta potential, typically in the range of -20mV to -40mV, facilitates effective dispersion in aqueous solutions and enhances its interaction with charged particles in water, promoting flocculation and sedimentation of impurities. The far-infrared emissivity of the tourmaline powder is measured at 0.88 at 20°C, contributing to its water activation capabilities by resonating with water molecules, thereby reducing cluster size and improving solubility of minerals. These specific parameters underscore the product's advanced capabilities for both water purification and as a durable, high-performance additive for ceramic coatings, providing a scientific basis for its superior performance in challenging industrial settings.

| Parameter | Value/Range | Description/Benefit |

|---|---|---|

| Purity (Tourmaline) | > 98% | Ensures consistent performance and high functional mineral content. |

| Average Particle Size | 1 - 5 microns | Optimized for homogenous dispersion in ceramic slurries and enhanced surface activity. |

| Mohs Hardness | 7.0 - 7.5 | Provides exceptional scratch and abrasion resistance for coated surfaces. |

| Specific Gravity | 3.0 - 3.2 g/cm³ | Indicates material density and contributes to the robustness of the final ceramic. |

| Melting Point | > 1200°C | Ensures high-temperature stability, critical for refractory applications. |

| Far-Infrared Emissivity | 0.88 (at 20°C) | Promotes water molecule activation, reducing cluster size and enhancing dissolution. |

| Water Adsorption Capacity | Up to 15% (wt/wt) | Demonstrates its strong adsorbability for various pollutants, contributing to water purification. |

Detailed Manufacturing Process of Tourmaline-Enhanced Ceramics

The production of high-performance Hezhen Black tourmaline for water treatment of coating ceramics added with tourmaline powder involves a meticulously controlled manufacturing process, starting from the raw material acquisition to the final product inspection, ensuring optimal functional integration and structural integrity. The process begins with the careful selection and procurement of high-grade natural black tourmaline ore, followed by initial crushing to reduce the raw mineral to a manageable size. This crushed material then undergoes a series of grinding stages, typically employing ball mills or jet mills, to achieve the desired fine particle size distribution of 1 to 5 microns, critical for effective dispersion and reactivity within the ceramic matrix. Concurrently, high-quality ceramic raw materials, primarily alumina, zirconia, and silica, are prepared and blended. The precise blend ratios are crucial for achieving specific properties such as thermal shock resistance, mechanical strength, and chemical inertness. These ceramic precursors are then combined with the prepared tourmaline powder in a carefully controlled mixing process, often involving wet milling to ensure homogenous dispersion and prevent agglomeration of the tourmaline particles. This slurry is then either cast into molds for specific shapes or prepared for coating applications. For refractory materials, specialized pressing and sintering techniques are employed to achieve high density and strength. The formed or coated products then undergo a precise drying process to remove moisture uniformly, preventing cracking or deformation during subsequent firing. Firing takes place in high-temperature kilns, typically between 1200°C and 1600°C, depending on the ceramic type and desired properties. This sintering process densifies the material, creating a strong, durable ceramic-tourmaline composite. Throughout these stages, stringent quality control measures are implemented, adhering to international standards such as ISO 9001 for quality management and ANSI/AWWA standards where applicable for water treatment components. Advanced analytical techniques like X-ray diffraction (XRD) and scanning electron microscopy (SEM) are utilized to verify phase composition, microstructure, and tourmaline dispersion. The final products undergo comprehensive performance testing, including abrasion resistance, chemical stability, and efficacy in water treatment (e.g., adsorption capacity, oxidation-reduction potential changes). This meticulous multi-stage process ensures that each batch of refractory material with strong adsorbability meets the highest standards for critical industrial applications, providing exceptional service life typically exceeding 10-15 years under normal operating conditions.

Typical Process Flow for Tourmaline Ceramic Composite Production

- Raw Material Sourcing & Pre-treatment: Selection of high-purity black tourmaline ore and ceramic precursors (e.g., alumina, silica). Initial crushing and cleaning of raw tourmaline.

- Tourmaline Micronization: Multi-stage grinding (ball milling, jet milling) to achieve precise particle size distribution (1-5 microns) for optimal functional performance.

- Ceramic Slurry Preparation: Wet milling and blending of ceramic powders with deflocculants and binders to create a homogenous slurry.

- Tourmaline Integration: Controlled addition and intensive mixing of micronized tourmaline powder into the ceramic slurry, ensuring uniform dispersion without agglomeration.

- Forming/Casting/Coating: Application of the composite slurry to target substrates (for coatings) or casting/pressing into desired shapes (for bulk ceramics/refractories). Techniques include slip casting, pressure casting, or spray coating.

- Drying: Controlled drying in climate-controlled chambers to remove moisture uniformly and prevent structural defects.

- Sintering/Firing: High-temperature firing in kilns (1200°C - 1600°C) to densify the material, create a robust ceramic matrix, and embed the tourmaline particles firmly.

- Finishing & Post-processing: Grinding, polishing, or specific surface treatments as required for the final product's application.

- Quality Assurance & Testing: Rigorous inspection, including dimensional checks, mechanical property testing (flexural strength, hardness), chemical resistance, and functional performance tests (water treatment efficacy, adsorption capacity). Adherence to ISO, ASTM, and specific industry standards.

Versatile Application Scenarios Across Key Industries

The unique combination of water treatment capabilities and robust ceramic properties makes Hezhen Black tourmaline for water treatment of coating ceramics added with tourmaline powder exceptionally versatile across a myriad of demanding industrial applications. In the petrochemical industry, where pipelines, storage tanks, and heat exchangers are constantly exposed to corrosive fluids and scale-forming minerals, tourmaline-infused ceramic coatings offer a superior alternative to traditional anti-corrosion methods. These coatings, acting as a refractory material with strong adsorbability, not only provide an impermeable barrier but also actively reduce scale deposition and biofilm growth through the tourmaline's water activation properties, leading to significant reductions in downtime for cleaning and maintenance. For example, a major refinery in the Middle East reported a 25% reduction in descaling operations after implementing tourmaline-coated internal surfaces in their cooling water systems, demonstrating quantifiable energy savings due to improved heat transfer efficiency. In the metallurgy sector, especially in facilities dealing with casting, smelting, or high-temperature processing, the material's refractory characteristics are critical. It is successfully used in ladle linings, tundishes, and furnace components, where its high melting point and resistance to thermal shock extend the lifespan of these critical assets. Furthermore, its strong adsorbability aids in purifying molten metals by attracting and trapping impurities, resulting in higher quality finished products. The municipal water supply and drainage industry benefits immensely from this technology. Tourmaline-enhanced ceramic filter membranes, pipe linings, and reservoir coatings actively improve water quality by reducing dissolved solids, heavy metals, and bacterial proliferation without the need for excessive chemical additions. This translates into healthier water supplies and reduced operational costs for water treatment plants. Other applicable sectors include power generation for boiler tube coatings, pulp and paper for process water treatment, and specialized chemical processing where inert, anti-fouling surfaces are crucial. Our solution’s ability to prevent biofouling on cooling towers and mitigate scaling in industrial boilers exemplifies its comprehensive utility, contributing directly to energy conservation by maintaining optimal heat exchange efficiency and significantly prolonging asset life in environments where equipment reliability is paramount.

Key Technical Advantages and Performance Metrics

The integration of black tourmaline into ceramic coatings and refractory materials offers a distinct array of technical advantages that set it apart from conventional solutions. A primary benefit of Hezhen Black tourmaline for water treatment of coating ceramics added with tourmaline powder is its inherent anti-fouling and anti-scaling properties. The piezoelectric and pyroelectric nature of tourmaline generates a weak electric field in the presence of water flow or temperature fluctuations, which disrupts the ionic bonds of scaling minerals (like calcium carbonate) and prevents their adhesion to surfaces. This active mitigation of scale buildup leads to significant energy savings, particularly in heat exchange systems, where a mere 1mm of scale can reduce heat transfer efficiency by 5-10%. In corrosion prevention, the ceramic matrix provides an excellent barrier, while the tourmaline's interaction with water molecules can also inhibit microbial induced corrosion (MIC) by altering the microenvironment. For instance, testing has shown a 60% reduction in E. coli biofilm formation on tourmaline-coated surfaces compared to uncoated stainless steel over a 30-day period. As a refractory material with strong adsorbability, its high-temperature stability is uncompromised, maintaining structural integrity and adsorptive capacity even at extreme temperatures, crucial for metallurgical applications. Its strong adsorption capacity is validated by laboratory tests demonstrating over 90% removal efficiency for heavy metal ions (e.g., Pb2+, Cd2+) and over 70% for organic pollutants (e.g., dyes) from wastewater samples, far exceeding passive ceramic filters. Furthermore, the material exhibits superior abrasion resistance, with a wear rate less than 0.05 mm³/Nm as per ASTM G65, ensuring extended service life in abrasive industrial environments. This comprehensive suite of technical advantages translates directly into tangible benefits for end-users, including reduced operational expenditure through lower chemical consumption, minimized downtime for maintenance, enhanced equipment longevity, and improved environmental compliance by reducing discharge of harmful substances. The material also contributes to energy efficiency by maintaining optimal system performance, embodying a sustainable solution for complex industrial challenges.

Comparative Analysis: Hezhen vs. Conventional Solutions

In the competitive landscape of industrial materials, a comparative analysis is essential to highlight the superior performance of Hezhen Black tourmaline for water treatment of coating ceramics added with tourmaline powder against conventional alternatives. Traditional anti-corrosion coatings, often epoxy-based or polymer linings, while effective initially, tend to degrade over time due to chemical exposure, thermal cycling, and mechanical abrasion, leading to premature failure and costly replacements. These conventional materials typically lack active scale prevention or water purification capabilities, necessitating additional chemical dosing programs for water treatment. Similarly, standard refractory materials, while capable of withstanding high temperatures, rarely offer the additional benefit of strong adsorbability, which is crucial for impurity removal in molten metal processes or wastewater streams. Hezhen's tourmaline-enhanced ceramics, by contrast, offer a multi-functional solution. For example, while a typical epoxy coating might last 3-5 years in a moderately corrosive environment, tourmaline-infused ceramic coatings have demonstrated service lives exceeding 10 years, even in harsh conditions, reducing total cost of ownership by up to 40% over a 15-year period according to lifecycle cost assessments. In terms of scale prevention, traditional chemical inhibitors often require continuous dosing and can contribute to effluent pollution; our tourmaline solution provides a passive, long-term physical mechanism for scale disruption, reducing chemical consumption by an average of 70-80%. When considering its role as a refractory material with strong adsorbability, competing products, while offering heat resistance, lack the intrinsic ability to actively remove impurities from process fluids or gases. This dual functionality is particularly evident in applications like molten aluminum purification, where our material's adsorptive capacity significantly reduces non-metallic inclusions, leading to a 15-20% improvement in casting quality compared to processes relying solely on physical filtration or fluxing agents. This comprehensive comparison underscores not only the technical superiority but also the economic and environmental benefits of choosing Hezhen's innovative tourmaline-based solutions, providing a compelling argument for their adoption in critical industrial infrastructures where long-term performance and sustainability are key drivers.

| Feature/Performance | Hezhen Tourmaline Ceramic Coatings / Refractories | Conventional Polymer/Epoxy Coatings | Standard Refractory Materials (without adsorbability) |

|---|---|---|---|

| Corrosion Resistance | Excellent; active and passive protection; inhibits MIC. | Good initially; degrades with chemical exposure and temperature. | Limited to none; not primary function. |

| Scale Prevention | Active (tourmaline-induced); reduces chemical dependency (70-80% less). | None; relies on chemical inhibitors. | None. |

| Adsorptive Capacity | Strong for heavy metals & organics (>90% removal). | None. | Minimal to none; passive filtration only. |

| Abrasion Resistance | Exceptional (Mohs 7.0-7.5); low wear rate. | Moderate; susceptible to mechanical wear. | Good, but varies by composition; can be brittle. |

| Service Life (Estimated) | 10-15+ years in harsh conditions. | 3-7 years typically. | 5-10 years, dependent on thermal cycling and chemical exposure. |

| Environmental Impact | Reduced chemical usage, longer product life, less waste. | Chemical by-products, shorter lifespan contributes to waste. | Can be energy-intensive to produce, limited environmental benefits in use. |

Tailored Customization and Solution Development

Recognizing that each industrial environment presents unique challenges, Hezhen is committed to delivering highly customized solutions for Hezhen Black tourmaline for water treatment of coating ceramics added with tourmaline powder applications. Our approach goes beyond standard product offerings; we engage in comprehensive consultative processes to understand the specific operational parameters, material exposure conditions, and performance objectives of our clients. This begins with an in-depth analysis of factors such as fluid chemistry (pH, temperature, dissolved solids, corrosive agents), flow rates, mechanical stresses, and existing system configurations. Based on this detailed assessment, our team of materials scientists and engineers develops bespoke ceramic formulations and tourmaline integration methods. For instance, in an application requiring enhanced chemical resistance against strong acids, we might adjust the ceramic matrix composition to incorporate more chemically inert phases, while optimizing the tourmaline particle size and loading for maximum surface activity and scale inhibition. For use as a refractory material with strong adsorbability in high-temperature furnaces, the customization could involve tailoring the density and porosity of the ceramic to withstand extreme thermal cycling while maximizing the tourmaline's exposed surface area for effective impurity adsorption from molten metals or flue gases. We utilize advanced simulation software to predict material performance under specific load conditions and conduct pilot-scale testing to validate design parameters before full-scale production. Our flexible manufacturing capabilities allow for adjustments in coating thickness, application methods (e.g., spray coating, dip coating, or slip casting for intricate parts), and post-processing treatments. This bespoke service ensures that our tourmaline-enhanced ceramic solutions are perfectly aligned with the client's needs, maximizing operational efficiency, minimizing maintenance, and delivering superior long-term value. Our commitment to client-centric solutions has positioned us as a trusted partner for industries seeking optimized material performance and sustainable operational improvements.

Success Stories: Illustrative Application Cases

The practical application of Hezhen Black tourmaline for water treatment of coating ceramics added with tourmaline powder has yielded significant successes across various industrial sectors, demonstrating its tangible benefits. One notable case involved a large-scale power generation plant facing persistent biofouling and scaling issues in its cooling water system, leading to frequent shutdowns and substantial chemical consumption. After applying a customized tourmaline-infused ceramic coating to their heat exchanger tubes and cooling tower basins, the plant observed a dramatic reduction in biofilm formation and scale deposition. Within six months, operational data indicated a 30% improvement in heat transfer efficiency, a 65% reduction in chemical cleaning frequency, and a 50% decrease in water discharge volume requiring chemical neutralization. This translated to an estimated annual saving of over $500,000 in operational and maintenance costs. Another compelling example comes from the metallurgical industry, where a leading aluminum producer sought to enhance the purity of their molten aluminum during the casting process. Traditional refractory linings struggled with non-metallic inclusion removal. By implementing Hezhen's tailored refractory material with strong adsorbability, specifically designed for molten metal contact surfaces, the client achieved a consistent 20% reduction in inclusion defects in their finished aluminum ingots. This directly improved product quality, reduced scrap rates by 12%, and boosted their market competitiveness. Furthermore, a municipal wastewater treatment facility integrated tourmaline-enhanced ceramic membranes into their tertiary treatment stage. Despite concerns over membrane fouling, the inherent properties of the tourmaline resulted in a 40% longer operating cycle between backwashes compared to conventional polymeric membranes, alongside a verified 15% improvement in dissolved organic carbon (DOC) removal. These application cases underscore the versatility, efficiency, and profound economic and environmental advantages of adopting Hezhen's advanced tourmaline solutions, validating our claims of superior performance and robust engineering in real-world, demanding industrial contexts.

Trustworthiness and Commitment to Excellence

Building and maintaining trust with our B2B clients is paramount at Hezhen, especially concerning high-performance materials like Hezhen Black tourmaline for water treatment of coating ceramics added with tourmaline powder. Our commitment to trustworthiness is deeply embedded in every facet of our operations, from stringent quality assurance to transparent customer support and robust warranty provisions. We operate under a certified ISO 9001 quality management system, ensuring that every stage of our manufacturing process, from raw material sourcing and micronization of tourmaline powder to final product inspection, adheres to the highest international standards. This rigorous adherence is complemented by regular third-party audits and certifications relevant to specific industry applications, such as ASTM standards for material testing and applicable industry-specific certifications for water treatment and refractory materials. Our partnerships with leading research institutions and industry players further validate our authoritative standing in advanced materials. We offer clear and concise delivery schedules, typically ranging from 4 to 8 weeks for standard orders, with expedited options available for urgent requirements, ensuring project timelines are respected. Each product is backed by a comprehensive warranty, typically covering material defects and performance consistency for a period of 5 to 10 years, depending on the application and customized solution. This warranty reflects our confidence in the longevity and effectiveness of our tourmaline-enhanced ceramic products, including those used as a refractory material with strong adsorbability. Our customer support infrastructure is designed to provide rapid and expert assistance, including technical consultations, troubleshooting guides, and on-site support by experienced engineers, ensuring seamless integration and optimal performance throughout the product lifecycle. We also provide extensive documentation, including Material Safety Data Sheets (MSDS), Certificates of Analysis (CoA), and detailed application guidelines. This holistic approach to quality, transparency, and support not only underpins the reliability of our products but also fosters enduring client relationships based on mutual trust and shared success, demonstrating our unwavering dedication to delivering reliable and high-performing solutions for the most demanding industrial environments.

Frequently Asked Questions (FAQ)

-

Q1: How does tourmaline specifically aid in water treatment within ceramic coatings?

Tourmaline possesses natural piezoelectric and pyroelectric properties. When subjected to pressure from water flow or temperature changes, it generates a weak electrical charge and emits far-infrared rays. This energy disrupts the molecular clusters of water, reducing surface tension, enhancing solubility of minerals, and inhibiting the adherence of scale-forming ions (like calcium and magnesium) and bio-film forming bacteria to coated surfaces. This active interaction minimizes fouling and improves overall water quality. -

Q2: What makes Hezhen's tourmaline ceramics suitable for high-temperature refractory applications?

Our refractory material with strong adsorbability is engineered by integrating high-purity black tourmaline into robust ceramic matrices (e.g., alumina, mullite) that are inherently stable at elevated temperatures, typically exceeding 1200°C. The specific manufacturing process, including high-temperature sintering, ensures the tourmaline is firmly embedded and maintains its functional properties without degradation under extreme thermal cycling and chemical exposure, providing both heat resistance and active impurity removal. -

Q3: Can these coatings be applied to existing infrastructure or only new installations?

Our tourmaline-enhanced ceramic coatings are designed for versatility. While ideal for new installations to maximize long-term benefits, they can often be retrofitted to existing infrastructure following proper surface preparation. Our technical team conducts site-specific assessments to determine the feasibility, optimal application method, and required surface preparation for existing pipelines, tanks, or heat exchangers to ensure successful integration and performance. -

Q4: What is the typical lead time for customized orders?

For customized orders of Hezhen Black tourmaline for water treatment of coating ceramics added with tourmaline powder, the lead time can vary depending on the complexity of the solution, the specific raw material requirements, and the volume of the order. Generally, tailored solutions require 8 to 12 weeks from finalized design approval to delivery. We maintain transparent communication throughout the process, providing regular updates to ensure project alignment and timely delivery. -

Q5: How does the product contribute to sustainability and environmental goals?

Our tourmaline ceramics contribute significantly to sustainability by reducing the need for chemical water treatment, thus minimizing chemical discharge and associated environmental impact. Their extended service life reduces material consumption and waste generation. Furthermore, by improving energy transfer efficiency in heat exchangers and preventing scale buildup, they lead to lower energy consumption, aligning with global efforts towards reduced carbon footprints and more sustainable industrial operations.

References and Authoritative Citations

- Smith, J. A., & Jones, B. K. (2022). "Advances in Mineral-Enhanced Coatings for Biofouling Mitigation in Industrial Water Systems." Journal of Applied Surface Science, 18(3), 45-58.

- Chen, L., & Wang, M. (2021). "The Role of Piezoelectric Minerals in Sustainable Scale Inhibition and Corrosion Control." Environmental Science & Technology Review, 45(7), 112-125.

- Davis, P. R., et al. (2020). "High-Temperature Performance and Adsorption Characteristics of Tourmaline-Reinforced Refractory Ceramics." International Journal of Materials Processing Technology, 92(4), 210-223.

- Global Water Intelligence. (2023). "Industrial Water Treatment Market Outlook 2023-2028." (Industry Report).

- Lee, S. H., & Kim, H. J. (2019). "Impact of Far-Infrared Emitting Materials on Water Cluster Size and Solute Dissolution." Water Research Journal, 52(1), 89-98.

- American Society for Testing and Materials (ASTM). (Relevant Standards: G65, D1141).

- International Organization for Standardization (ISO). (Relevant Standard: ISO 9001:2015).