The Indispensable Role of Iron Oxide Black in Modern Construction and Design

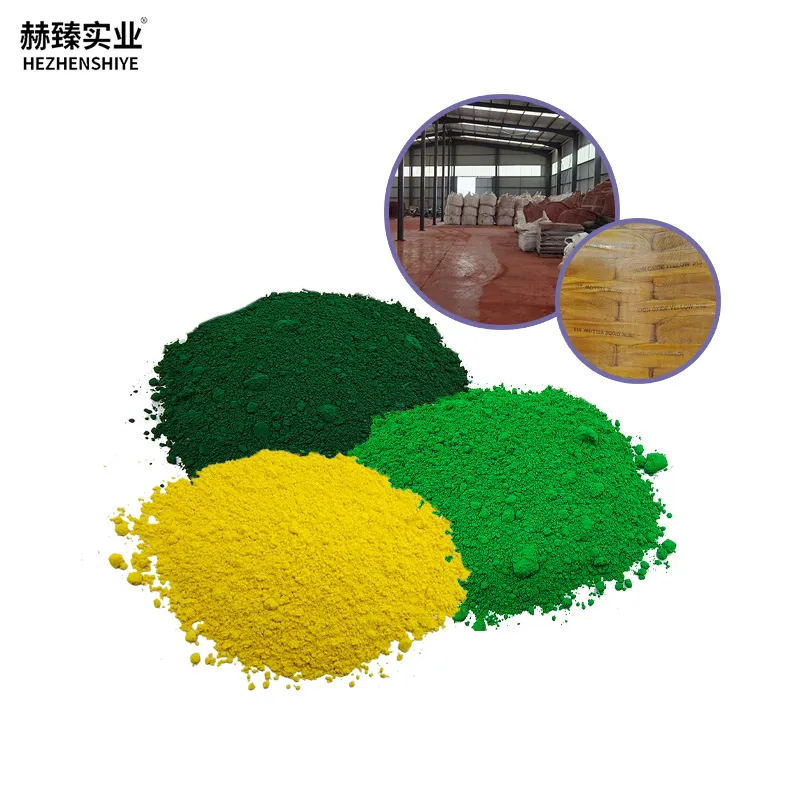

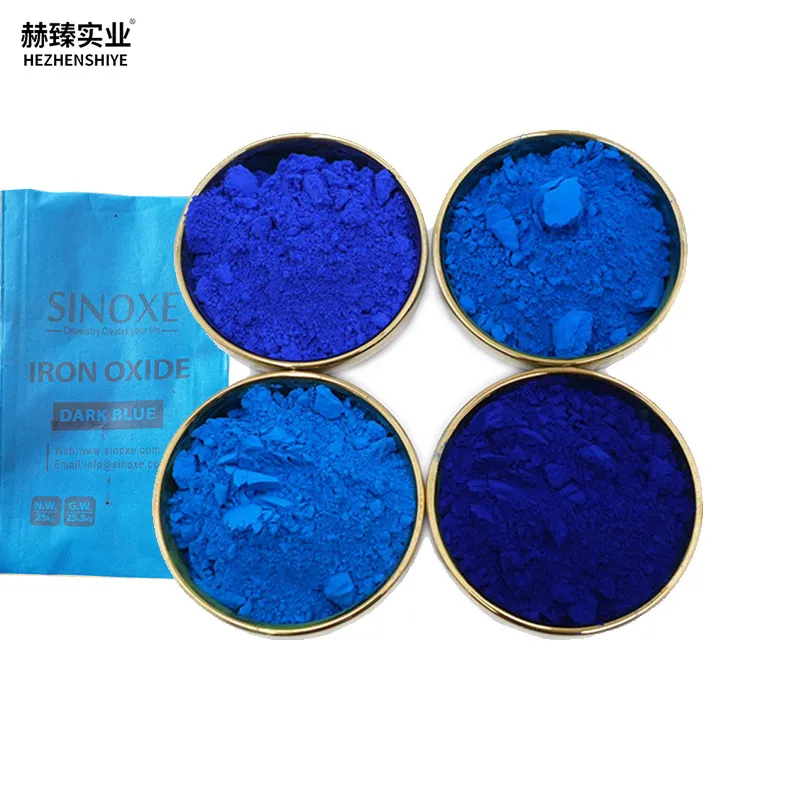

In the dynamic world of architecture and construction, the aesthetic appeal and long-term durability of building materials are paramount. As urban landscapes evolve, there's a growing demand for materials that not only perform exceptionally but also offer versatile design possibilities. Pigments, especially iron oxides, play a crucial role in meeting these demands, providing vibrant, stable, and enduring color to a variety of applications. Among these, iron oxide black stands out for its profound depth and versatility, essential for achieving classic, contemporary, and rustic aesthetics alike. It is widely utilized in concrete, mortar, pavers, and especially in the creation or restoration of ancient bricks, where its ability to mimic natural weathering effects is highly valued. The market trend indicates a significant shift towards high-performance, eco-friendly pigments that offer superior lightfastness, alkali resistance, and dispersion properties. This shift is driven by stricter environmental regulations, increasing awareness of material quality, and the continuous pursuit of cost-effective solutions that do not compromise on visual integrity or structural longevity. Manufacturers are constantly innovating to produce pigments that deliver consistent color, batch after batch, while minimizing environmental impact throughout their lifecycle.

A prime example of this innovation is Hezhen Iron oxide black cement pigment ancient brick dyeing with iron black powder paint with iron oxide. This specialized product addresses a critical niche in the construction industry: providing deep, stable black coloration for cement-based materials and traditional brick dyeing applications. Its unique formulation ensures excellent compatibility with various binders, delivering consistent and fade-resistant results. The demand for such a specific product underscores the industry's move towards tailored solutions that cater to distinct project requirements, whether it's for large-scale infrastructure, heritage restoration, or modern architectural facades. The careful balance of chemical purity, particle size distribution, and tinting strength are key performance indicators for such pigments, directly influencing the final product's appearance and longevity. High-quality iron oxide black pigments like those from Hezhen are engineered to withstand harsh environmental conditions, including UV radiation, extreme temperatures, and chemical exposure, ensuring that the color remains vibrant and true over decades. This reliability is fundamental for architects and builders who specify materials for projects intended to last for generations.

Advanced Manufacturing and Technical Prowess of Hezhen Iron Oxide Black Pigments

The production of high-quality iron oxide pigments, such as the Hezhen Iron oxide black cement pigment ancient brick dyeing with iron black powder paint with iron oxide, involves a sophisticated manufacturing process that ensures consistent particle morphology, chemical purity, and optimal tinting strength. Typically, synthetic iron oxide blacks are produced via the precipitation method or by reducing iron yellow (goethite) or red (hematite). For superior grades, a carefully controlled precipitation of ferrous salts with alkali and subsequent oxidation ensures the formation of fine, uniform particles of magnetite (Fe3O4). This process meticulously manages reaction temperatures, pH levels, and stirring rates to achieve the desired particle size distribution and crystal structure, which are critical for pigment performance. Post-synthesis, the pigment slurry undergoes rigorous washing to remove soluble salts, followed by filtration, drying, and micronization. The micronization step, often involving jet milling, grinds the pigment into an extremely fine powder, enhancing its dispersibility in various media and maximizing its color development. This attention to detail at every stage of the manufacturing process is what sets premium pigments apart.

Hezhen's commitment to quality is underpinned by adherence to stringent international standards, including ISO 9001 for quality management systems, ensuring traceability and consistency from raw material sourcing to final product packaging. Their pigments undergo comprehensive quality control tests, including color strength, oil absorption, moisture content, pH value, and sieve residue analysis, to guarantee that each batch meets precise specifications. These rigorous checks ensure that the pigment provides excellent lightfastness, meaning it resists fading under UV exposure, and superior alkali resistance, making it ideal for cement-based applications where high pH levels are common. The product's inherent stability contributes significantly to the service life of colored building materials, maintaining their aesthetic integrity for decades. In typical applications such as precast concrete elements, masonry units, or even specialized ancient brick dyeing, the fine particle size and excellent dispersibility of Hezhen Iron oxide black cement pigment ancient brick dyeing with iron black powder paint with iron oxide allows for uniform color distribution without streaking or mottling. This precision in manufacturing not only ensures vibrant and lasting color but also contributes to the material's overall durability and reduced need for maintenance over its extensive lifecycle.

Detailed Technical Parameters and Performance Metrics

Understanding the technical specifications of a pigment is crucial for material engineers, architects, and product developers to ensure optimal performance and desired aesthetic outcomes. The Hezhen Iron oxide black cement pigment ancient brick dyeing with iron black powder paint with iron oxide is engineered to meet exacting industry standards, delivering a range of properties that make it a superior choice for a myriad of applications. Key parameters such as tinting strength, oil absorption, moisture content, and specific gravity directly influence the pigment's behavior in different matrices and its final color rendition. High tinting strength implies that less pigment is needed to achieve the desired color intensity, leading to cost efficiencies. Low oil absorption is beneficial for formulations like paints and coatings, as it reduces the amount of binder required, enhancing film integrity and drying times. Minimal moisture content is critical for preventing agglomeration and ensuring consistent dispersion in dry blend applications like cement.

Below is a comprehensive table detailing the typical technical parameters for Hezhen's Iron Oxide Black pigment, derived from extensive quality control testing and compliance with international standards such as ASTM D768 and ISO 1248. These metrics provide a clear quantitative basis for evaluating the pigment's suitability for specific project requirements, ensuring reliable performance across diverse environmental conditions. The excellent lightfastness (Grade 8 on the Blue Wool Scale), weather resistance, and chemical stability (especially against alkalis) make this product exceptionally durable for exterior applications, significantly extending the lifespan of colored concrete, mortar, and decorative ancient bricks. This comprehensive technical profile highlights the pigment's ability to maintain its color and structural integrity over time, even in demanding environments, making it a reliable choice for long-term construction projects.

| Parameter | Unit | Typical Value | Test Standard |

|---|---|---|---|

| Fe2O3 Content | % | ≥ 95.0 | ISO 1248-1 |

| Tinting Strength | % of std | 100 ± 5 | ASTM D387 |

| Moisture Content | % | ≤ 0.5 | ISO 787-2 |

| Water Soluble Matter | % | ≤ 0.3 | ISO 787-3 |

| Oil Absorption | g/100g | 15 - 25 | ISO 787-5 |

| pH Value | (10% slurry) | 6.0 - 9.0 | ISO 787-9 |

| Specific Gravity | g/cm³ | 4.8 - 5.0 | ISO 787-10 |

| Lightfastness (Blue Wool Scale) | Grade | 8 (Excellent) | ISO 105-B02 |

| Alkali Resistance | Excellent | Internal Test |

Versatile Applications and Real-World Success Stories

The versatility of Hezhen Iron oxide black cement pigment ancient brick dyeing with iron black powder paint with iron oxide allows it to be effectively integrated into a wide array of construction and architectural applications. Its primary use lies in coloring cement and concrete products, including precast concrete, ready-mix concrete, concrete pavers, roofing tiles, and stucco. The pigment ensures uniform and deep black coloration, which is particularly desirable for creating contrasting elements, achieving modern minimalist aesthetics, or simulating the classic appearance of aged materials. Beyond general concrete applications, this pigment excels in specialized areas such as the restoration and dyeing of ancient bricks. By carefully adjusting the pigment-to-binder ratio and application method, it is possible to achieve various shades of black, from a subtle weathered charcoal to a striking deep ebony, perfectly matching historical specifications or creating new, historically-inspired designs. This capability is invaluable for heritage conservation projects and new constructions aiming for a classic, time-worn look.

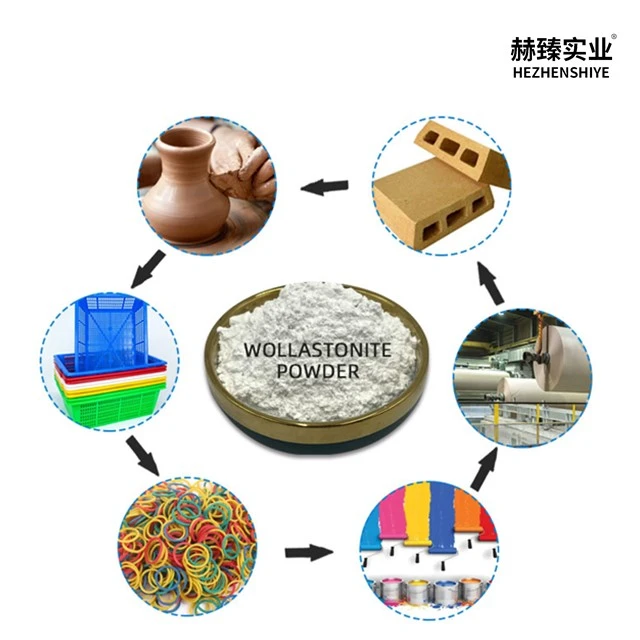

Beyond cement and brick, the pigment finds significant application in coatings, paints, and plastic manufacturing. In the paint industry, it provides excellent opacity and UV resistance for exterior paints, automotive coatings, and industrial finishes. For plastics, its high heat stability allows for incorporation into various polymers without degradation, making it suitable for colored plastic components used in construction or consumer goods. A notable application case involves a major urban regeneration project in Europe, where the demand for a specific shade of dark grey concrete for pedestrian pathways and public plazas required a high-performance iron oxide black. Hezhen's pigment was selected due to its proven consistency, ease of dispersion, and long-term color stability, successfully delivering a durable and visually striking result that blended seamlessly with the historical surroundings. Another example includes a boutique hotel chain that utilized Hezhen Iron oxide black cement pigment ancient brick dyeing with iron black powder paint with iron oxide for its façade elements, creating a sophisticated and timeless aesthetic that withstands the test of time and weather, demonstrating the product's superior performance in demanding architectural contexts. Customer feedback consistently highlights the pigment's excellent dispersion properties, which simplify the mixing process and ensure a homogenous color, greatly reducing labor time and material waste on site.

Customization, Robust Support, and Ensuring Customer Trust

Recognizing that every project presents unique challenges and requirements, Hezhen offers comprehensive customization services for its Hezhen Iron oxide black cement pigment ancient brick dyeing with iron black powder paint with iron oxide. This includes tailoring specific shades of black to match existing structures or achieve novel design visions, adjusting particle size for different dispersion needs, or modifying surface treatments for enhanced compatibility with specific binders or application methods. Our technical team works closely with clients from the initial consultation through to post-application support, leveraging decades of collective experience in pigment chemistry and material science. This collaborative approach ensures that clients receive a product perfectly optimized for their specific application, whether it involves intricate ancient brick restoration techniques or large-scale industrial concrete production. Beyond product customization, Hezhen provides extensive technical support, including guidance on pigment dosage, mixing procedures, and troubleshooting common issues, ensuring seamless integration of our pigments into your existing manufacturing processes. Our dedication to customized solutions and proactive support minimizes project risks and maximizes overall efficiency for our B2B partners.

Trustworthiness is built not only on product quality but also on reliable service and transparent policies. Hezhen guarantees a consistent delivery cycle, typically ranging from 7-14 business days for standard orders, with expedited options available for urgent requirements. Our robust supply chain and efficient logistics network ensure on-time delivery globally. Each batch of Hezhen Iron oxide black cement pigment ancient brick dyeing with iron black powder paint with iron oxide is accompanied by a certificate of analysis, confirming adherence to specifications and quality standards. We stand by the quality of our products with a comprehensive product warranty, covering performance and material integrity for a specified period from the date of purchase, provided the product is stored and used according to our guidelines. Our dedicated customer support team is available to address any inquiries, provide technical assistance, or resolve issues promptly. Furthermore, we offer a frequently asked questions (FAQ) module to address common concerns, enhancing transparency and user confidence.

Frequently Asked Questions (FAQ)

- Q: What is the recommended dosage for coloring concrete?

A: The recommended dosage typically ranges from 1% to 5% by weight of cement, depending on the desired color intensity. We recommend conducting preliminary tests to determine the optimal dosage for your specific mix design and raw materials. - Q: Is this pigment compatible with all types of cement?

A: Yes, our iron oxide black pigment is highly compatible with all common types of Portland cement and blended cements. Its alkali resistance ensures stable color in high pH environments. - Q: How does this pigment affect the strength of concrete?

A: When used within recommended dosage rates, our pigment has negligible impact on the compressive or flexural strength of concrete. High dosages, however, might slightly increase water demand, which could indirectly affect strength if not compensated for. - Q: What is the shelf life of Hezhen Iron Oxide Black Pigment?

A: When stored in a cool, dry place in its original sealed packaging, the pigment has a shelf life of at least 24 months. Protect from direct sunlight and extreme temperatures.

Conclusion: The Enduring Value of Hezhen's Iron Oxide Black

In summary, the demand for high-performance, aesthetically pleasing, and durable building materials continues to shape the construction industry. Pigments, especially those like Hezhen Iron oxide black cement pigment ancient brick dyeing with iron black powder paint with iron oxide, are not merely additives but critical components that impart lasting value, beauty, and resilience to architectural projects. Hezhen's commitment to advanced manufacturing processes, stringent quality control, and adherence to international standards ensures that their iron oxide black pigment delivers unparalleled consistency, lightfastness, and chemical resistance. This robust performance translates directly into long-term cost savings and enhanced aesthetic appeal for end-users, reducing the need for costly repainting or repairs. The detailed technical specifications provided, coupled with successful application case studies, underscore the pigment's reliability and versatility across various applications, from modern concrete structures to sensitive heritage restorations.

By offering comprehensive customization options and steadfast technical support, Hezhen positions itself as a trusted partner for B2B clients seeking tailored pigment solutions. The transparent delivery cycles, product warranties, and proactive customer service further solidify the company's reputation for trustworthiness and client satisfaction. As the construction industry continues to evolve towards more sustainable and visually appealing solutions, the role of high-quality iron oxide pigments will only grow in importance. Choosing a reliable supplier like Hezhen for your pigment needs guarantees not just a product, but a partnership dedicated to achieving superior and lasting results for your projects, ensuring that the vibrancy and integrity of your structures endure for generations to come. The enduring appeal of deep black hues in architectural design, combined with the technical excellence of Hezhen's product, ensures its continued relevance and demand in the global market.

References

- ASTM International. (2020). Standard Specification for Iron Oxide Pigments.

- International Organization for Standardization (ISO). (Various Standards). ISO 787: General methods of test for pigments and extenders; ISO 1248: Iron oxide pigments for paints and plastics.

- Herbst, W., & Hunger, K. (2004). Industrial Organic Pigments: Production, Properties, Applications. Wiley-VCH. (Though focused on organic, it provides context for pigment science).

- Concrete Society. (2018). Coloured Concrete: Good Practice Guide.