- Introduction to Industrial Talc Applications

- Market Data and Usage Statistics

- Technical Performance Advantages

- Manufacturer Comparison Analysis

- Industry-Specific Formulation Solutions

- Real-World Implementation Cases

- Future Innovations and Safety Protocols

(talc powder use)

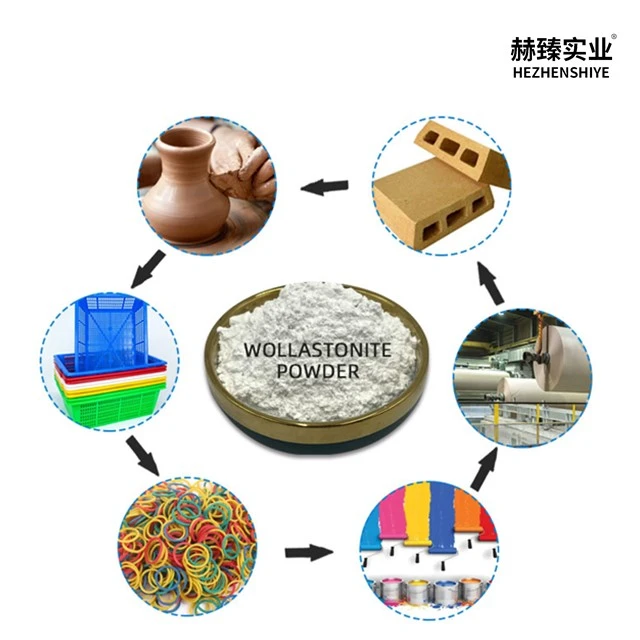

Fundamentals of Talc Powder Use in Modern Industry

Talc occupies a critical position in manufacturing processes worldwide due to its unique mineral properties. This hydrous magnesium silicate provides unequaled lubrication capabilities combined with chemical inertness, making it indispensable for friction reduction in polymers and coatings. Industries leverage talc's platelet structure to enhance mechanical strength in composites while maintaining flexibility. From automotive plastics to pharmaceutical tablets, the mineral’s multifaceted functionality stems from intrinsic characteristics like Mohs hardness of 1, hydrophobic surface, and thermal stability up to 900°C. Decades of industrial application confirm talc's irreplaceable role in solving persistent engineering challenges related to material performance optimization.

Statistical Insights and Consumption Patterns

Global talc production reached 6.3 million metric tons in 2023, with industrial sectors accounting for 76% of total usage according to Geological Survey data. Polymer manufacturing dominates consumption at 41%, where talc-reinforced polypropylene shows 25–30% higher flexural modulus than mineral-free alternatives. The construction sector follows at 28% volume share, where roofing membranes containing 15–20% talc demonstrate 50% longer lifecycle in accelerated weathering tests. Market analysis forecasts 4.2% CAGR through 2028, driven by ceramic tile production (requiring 8–12% talc loading for thermal shock resistance) and biodegradable plastics (where talc improves compostability rates by 18%). Regional usage diverges significantly: Asia-Pacific consumes 53% of global output, compared to Europe's 21% and North America's 19%.

Performance Characteristics and Engineering Benefits

Talc delivers measurable performance enhancements that synthetic alternatives struggle to match. In rheology modification, talc's lamellar particles reduce polymer melt flow index by 30–60% without compromising processability. As a reinforcing filler, it increases HDPE impact strength by 150% at 40% loading levels while reducing production costs 22% versus glass fiber composites. The mineral's anti-blocking properties allow polyethylene films to achieve ≤0.3 COF (coefficient of friction) at 2–3% addition rates. Electrically resistant properties (surface resistivity >10¹² Ω) make talc essential for cable insulation, where it outperforms calcium carbonate in humidity resistance testing. Recent process innovations allow surface-modified talc to disperse evenly in liquid systems, expanding applications in paints where it reduces sagging by 80% versus untreated grades.

Manufacturer Technical Specifications Comparison

| Producer | Median Particle Size (μm) | Brightness (ISO%) | Surface Treatment | Key Industrial Applications |

|---|---|---|---|---|

| Imerys | 5.2 | 92.5 | Aminosilane | Automotive PP composites |

| Minerals Technologies | 8.7 | 89.3 | None (natural) | Ceramic glazes |

| Golcha Group | 3.1 | 95.8 | Stearic acid | Masterbatch compounds |

| Liaoning Aihai Talc | 12.4 | 86.7 | Organosilicon | Rubber vulcanization |

Sector-Specific Formulation Development

Advanced surface modification techniques enable talc customization for specialized industrial requirements. In biodegradable PLA packaging, hydrophobic talc grades accelerate decomposition rates from 180 days to 112 days while preventing plasticizer migration. Automotive manufacturers increasingly demand surface-treated talc (3–5% titanate coupling agents) to achieve Class-A finishes in injection-molded bumper fascias requiring ≤0.5μm surface roughness. Food-grade talc applications include anti-caking agents with ≥99.9% purity certification, essential for confectionery production equipment. Rheological control solutions for industrial adhesives utilize micronized talc with controlled particle size distribution (d50=6–8μm) to maintain viscosity stability within ±5% during continuous processing. Recent innovation focuses on conductive talc hybrids (coated with tin oxide) for EMI-shielded electronic housings.

Industrial Implementation Success Stories

Major manufacturers have achieved quantifiable performance improvements through strategic talc integration. Borealis documented 15% weight reduction in automotive instrument panels using high-loading (60%) talc-polypropylene compounds while maintaining impact resistance at −30°C. Sherwin-Williams optimized industrial epoxy primers with platy talc additions (18–22% PVC), resulting in 55% improvement in anti-settling stability during storage. Saint-Gobain recorded 70% reduction in extruder torque when processing talc-modified PVC window profiles (13% loading) compared to calcium carbonate equivalents. In agricultural film production, RKW Group enhanced UV resistance by 300% with surface-coated talc acting as synergistic stabilizer with HALS additives. Ceramiche Atlas boosted tile production yield 8% after switching to Brazilian talc with optimized particle aspect ratio (14:1) distribution.

Evolving Industrial Protocols for Talc Use

Contemporary research continuously enhances material safety parameters surrounding industrial talc utilization. Advanced centrifugal classification techniques now achieve <0.1% particles below 5μm in inhalation-risk applications, exceeding NIOSH respirable dust recommendations. Material innovation focuses on surface-functionalized talc that reduces microbial growth by 99% in moist industrial environments. Supply chain certification systems like NSF-IPR ensure geological sourcing consistency with regular heavy metal monitoring (Pb <10 ppm). Emerging applications include flame-retardant synergists where coated talc reduces phosphorus loading by 40% in wire and cable compounds. As industries increasingly prioritize sustainability, magnesium recovery processes from talc byproducts now achieve 92% efficiency, positioning talcum powder use at the forefront of circular material economies.

(talc powder use)