Manufacturer provides calcium carbonate powder for papermaking materials plastic products rubber industry

2025.06.13

Calcium carbonate powder, chemically represented as CaCO₃, is one of the most abundant and versatile inorganic compounds. It occurs naturally in various forms, including limestone, chalk, and marble, and is a key component of shells, corals, and pearls. These natural sources, distributed globally with major deposits in China, the United States, India, and Turkey, serve as the primary raw materials for calcium carbonate production.

The manufacturing process of calcium carbonate powder involves both mining and synthetic methods, each with distinct characteristics tailored to various industrial needs. For natural calcium carbonate, the extraction process commences with the quarrying of limestone or marble from specialized mines. These quarries are carefully selected based on the purity and quality of the mineral deposits, ensuring that the extracted raw material meets stringent industry standards.

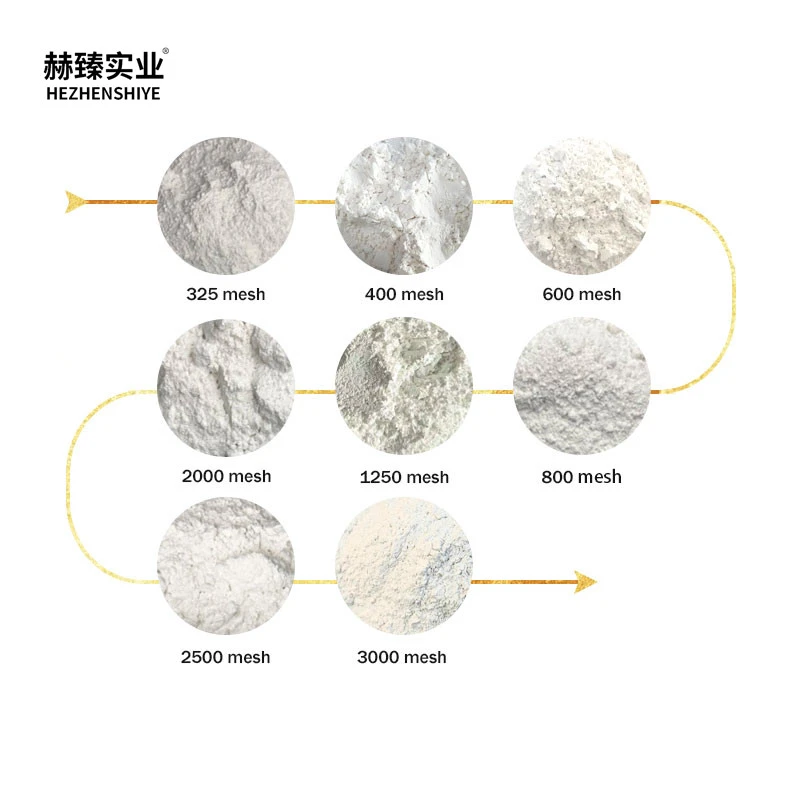

Once mined, the limestone or marble undergoes a series of meticulous mechanical processes. Initially, the large boulders are subjected to primary crushing using jaw crushers or gyratory crushers, reducing them into smaller, more manageable pieces. These intermediate fragments then proceed to secondary and tertiary crushing stages, often utilizing cone crushers or impact crushers, to further decrease their size. Following crushing, the material enters a grinding phase, where ball mills or vertical roller mills are commonly employed. These mills grind the calcium carbonate into fine particles, with the grinding process being carefully monitored to achieve the desired particle size distribution.

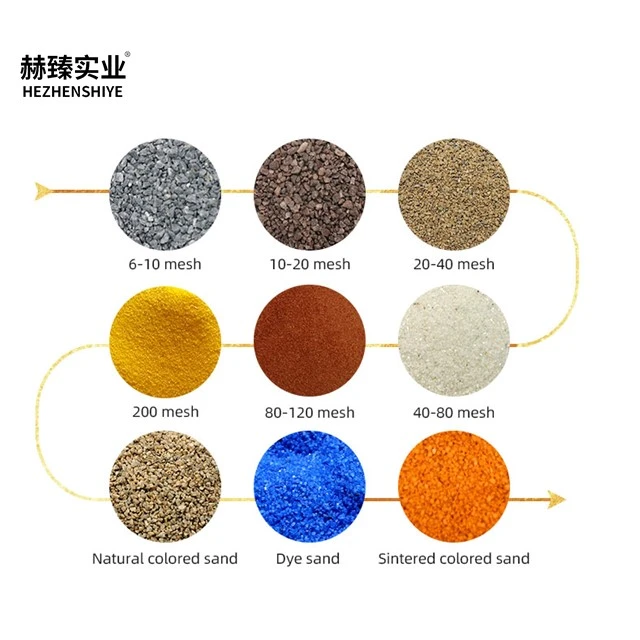

Particle classification is the final crucial step in the production of natural calcium carbonate. Air classifiers or wet classification systems are used to separate particles based on their size, density, and aerodynamic properties. This results in a product with a consistent particle size, typically ranging from a few micrometers to several hundred micrometers, making it suitable for applications such as paper filling, plastic reinforcement, and paint formulation.

Calcium carbonate powder’s wide-ranging applications stem from its unique physical and chemical properties. In the construction industry, it is a fundamental ingredient in cement, concrete, and mortar, enhancing strength, durability, and workability. In paper manufacturing, it acts as a filler, improving paper opacity, brightness, and printability while reducing production costs.

التالي

هذه هي المقالة الأخيرة