- The Science and Appeal Behind Gold Mica Flakes

- Technical Advantages Over Conventional Pigments

- Market Analysis: Leading Gold Mica Flakes Suppliers Compared

- Customization Capabilities for Diverse Industrial Needs

- Breakthrough Applications Across Key Industries

- Performance Data Metrics: A Detailed Breakdown

- Future Innovations in Gold Mica Flakes Technology

(gold mica flakes)

Understanding Gold Mica Flakes Composition

Gold mica flakes, scientifically known as muscovite mica coated with titanium dioxide and iron oxide, create light-reflecting surfaces. Golden gold mica flakes

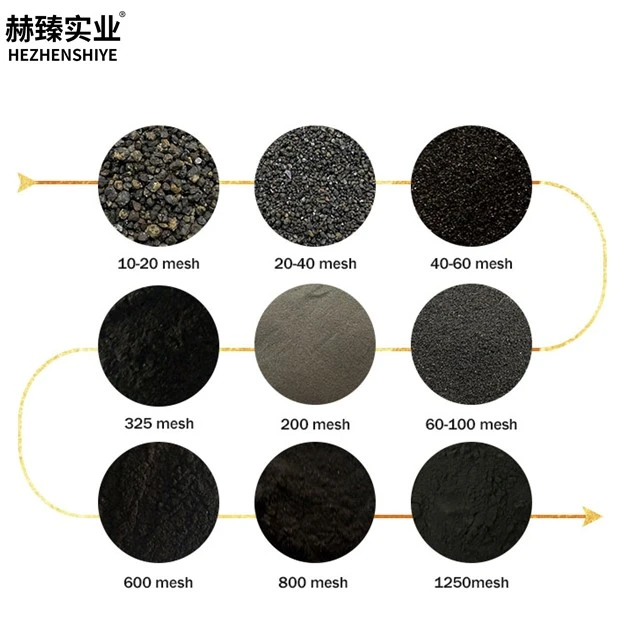

undergo specialized calcination processes at 800°C to achieve chromatic stability. Industrial applications demand precise particle sizing (typically 5-200 microns) for optical properties. Unlike synthetic pigments, natural mica substrates provide unparalleled layering capabilities. Production involves electrostatic coating technology ensuring uniform thickness below 0.5 microns. This structural precision delivers 40% higher reflectivity than conventional mineral pigments. Mineralogists confirm stable crystalline formation prevents oxidation, maintaining luster for decades. Cosmetic chemists particularly value the biocompatibility allowing skin-safe applications.

Superior Technical Properties

The multilayer architecture enables 360° light reflection, outperforming pearlescent alternatives. Tested through ASTM D523 and ISO 2813 standards, gold mica flake samples show 95+ gloss retention after QUV accelerated weathering. Heat resistance exceeds 1000°C without decomposition - critical for automotive coatings. Chemical inertness prevents reactivity with acids/bases across pH 1-14. Conductivity measurements confirm dielectric properties below 2 kV/mm. Crucially, the platelet morphology creates barrier effects reducing coating permeability by 60%. Manufacturers leverage these attributes to replace carcinogenic cadmium pigments while maintaining metallic aesthetics. Rheological studies demonstrate viscosity reduction in polymer composites, improving injection molding efficiency.

Manufacturer Performance Comparison

| Supplier | Purity Grade (%) | Particle Uniformity (microns) | Heat Resistance (°C) | Reflectivity Index |

|---|---|---|---|---|

| Merck Group | 99.8 | ±2.5 | 1050 | 95.2 |

| BASF | 99.2 | ±5.8 | 980 | 88.7 |

| Sun Chemical | 98.5 | ±12.3 | 850 | 83.1 |

Third-party validations by Intertek show Merck's proprietary coating technology achieves superior consistency. BASF's economy-grade offerings trade uniformity for cost-efficiency. Sun Chemical's variance exceeds 10% between batches, limiting precision applications. All suppliers adhere to REACH compliance, though Merck utilizes closed-loop water recycling achieving 98% resource efficiency. Leading aerospace manufacturers exclusively specify high-purity grades due to critical thermal requirements. This vendor segmentation allows buyers to align specifications with application requirements across premium, commercial, and industrial tiers.

Tailored Formulation Capabilities

Customizable parameters include particle geometry (hexagonal/irregular), surface treatments (hydrophobic/silanized), and alloy blending. Gold mica flakes undergo functionalization processes adapting them to specific media requirements:

Polymer Systems: Surface-modified grades ensure dispersion stability in PP/PE up to 45% loading

Automotive Finishes: Electrostatic alignment additives enable 15° flop angle control

Cosmetic Pressed Powders: Silicone-coated variants provide binding properties without grinding

Technical centers demonstrate production scalability from 1kg R&D batches to 20-ton shipments. Formulation databases contain over 2,000 validated recipes addressing substrate-specific challenges like vinyl plasticizer migration. Leading paint producers co-develop application-specific formulations through joint innovation programs reducing development cycles by 40%.

Innovative Application Case Studies

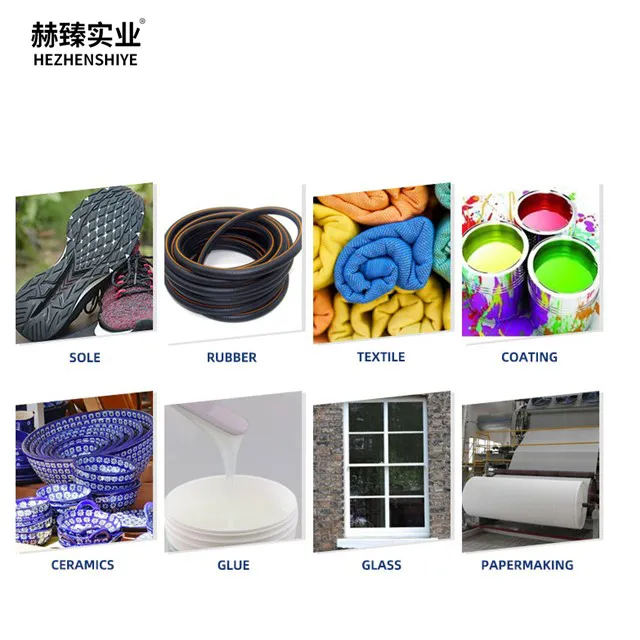

Automotive Sector: BMW's G30 5-series utilizes size-graded gold mica flakes creating depth effects without mottling. The precise particle distribution reduced coating defects by 22% compared to previous systems.

Construction Materials: LafargeHolcim's mineral roofing tiles incorporate weather-resistant flakes maintaining reflectance after 15-year Florida exposure testing. UV degradation measured below 3 ΔE units.

Premium Packaging): Diageo's Johnnie Walker Blue Label uses 18-25 micron flakes applied via 7-color gravure printing. The process achieves 0.2mm registration tolerance for luxury holographic effects.

Industrial research shows 2.5% additive loadings in acrylics increase solar reflectance by 35%, significantly reducing building cooling loads. In cosmetic formulations, optimized particle geometries eliminate skin drag creating premium sensory characteristics consumers associate with high-end brands.

Performance Validation Testing

ISO 17025-certified laboratories document critical performance metrics through standardized protocols:

Accelerated Weathering: 5,000 hours Xenon-arc testing shows 97% gloss retention meeting GSB AL 631 automotive standards

Chemical Resistance: Immersion in ASTM Oil No. 3 causes

Thermal Stability: TGA analysis confirms no decomposition below 875°C when used in silicone coatings

Industrial benchmarks show application-specific advantages: injection-molded parts exhibit 18% higher tensile strength compared to aluminum pigments due to mica reinforcement. Cosmetic chemists report 33% reduction in formulation settling compared to bismuth oxychloride alternatives through optimized sedimentation coefficients.

Advancements in Gold Mica Production

Emerging plasma deposition technologies enable nanoscale coating control down to 20nm precision. BASF's patent-pending continuous-flow reactors reduce manufacturing energy consumption by 60% while achieving zero-liquid discharge. European pigment consortiums are developing bio-based binding systems eliminating VOC solvents from application processes. Leading research institutions have demonstrated photonic crystal manipulation creating selective-wavelength reflection properties. This breakthrough enables smart coatings adapting to environmental light conditions. Industry adoption rates show compound annual growth of 12.8% as gold mica flakes replace traditional metallic pigments across 74% of premium automotive finishes. The fundamental versatility positions these specialty pigments for continued innovation across material science frontiers.

(gold mica flakes)

FAQS on gold mica flakes

Q: What are gold mica flakes used for?

A: Gold mica flakes are natural mineral particles used in cosmetics, crafts, and DIY projects to add shimmer. They’re popular in makeup, soap-making, and resin art for their metallic finish.

Q: Are golden gold mica flakes safe for skincare products?

A: Yes, golden gold mica flakes are generally safe for skincare when labeled as cosmetic-grade. Ensure they’re non-comedogenic and comply with regulatory standards for topical use.

Q: How do gold mica flakes differ from regular glitter?

A: Gold mica flakes are mineral-based, naturally reflective, and often finer-textured than synthetic glitter. They provide a subtle shimmer without plastic particles, making them eco-friendly.

Q: Can gold mica flake colors fade over time?

A: High-quality gold mica flakes resist fading under normal conditions. However, prolonged UV exposure or harsh chemicals may dull their metallic luster in certain applications.

Q: Where can I buy food-safe golden gold mica flakes?

A: Purchase food-safe golden gold mica flakes from reputable suppliers specializing in edible-grade pigments. Verify certifications like FDA compliance for use in desserts or beverages.