Navigating Industry Trends: The Crucial Role of Advanced Diatomite in Sustainable Development

The global industrial landscape is undergoing a profound transformation, driven by an increasing emphasis on environmental sustainability, resource efficiency, and circular economy principles. In this evolving paradigm, raw materials that offer multifaceted benefits across diverse sectors are gaining unparalleled prominence. Diatomite, a naturally occurring, porous siliceous sedimentary rock, stands at the forefront of this shift, particularly in its industrial-grade particulate form. Emerging trends highlight a significant surge in demand for high-performance filtration and adsorption media, driven by stringent environmental regulations concerning industrial wastewater discharge and the growing need for enhanced nutrient delivery and substrate aeration in advanced horticulture. Simultaneously, the ceramics industry is continuously seeking innovative additives that can improve material properties, reduce energy consumption during firing, and contribute to more durable and aesthetically pleasing end products. This confluence of needs positions specialized diatomite particles as indispensable components in achieving these ambitious goals.

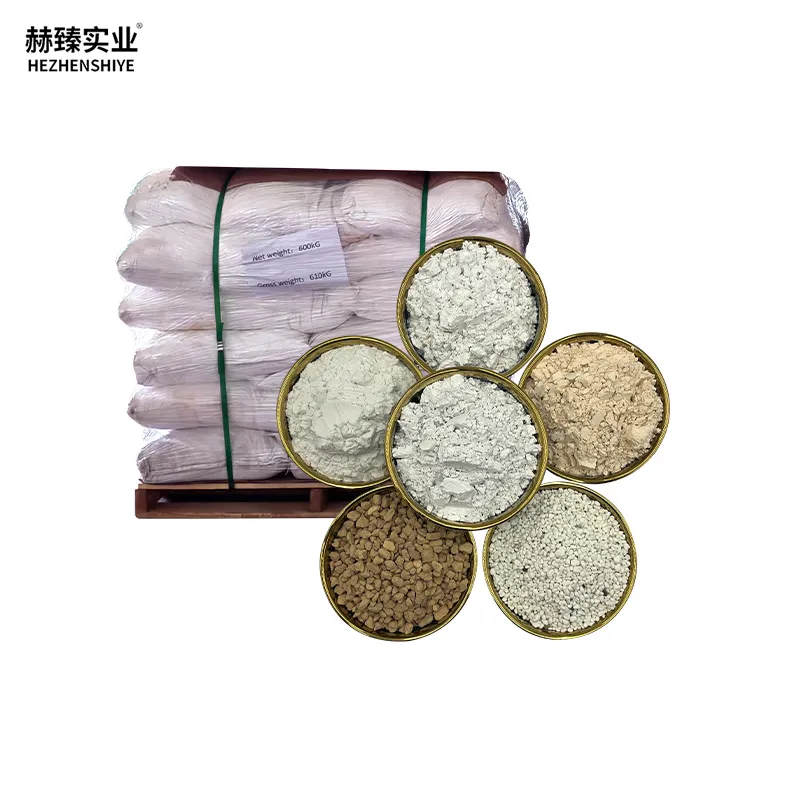

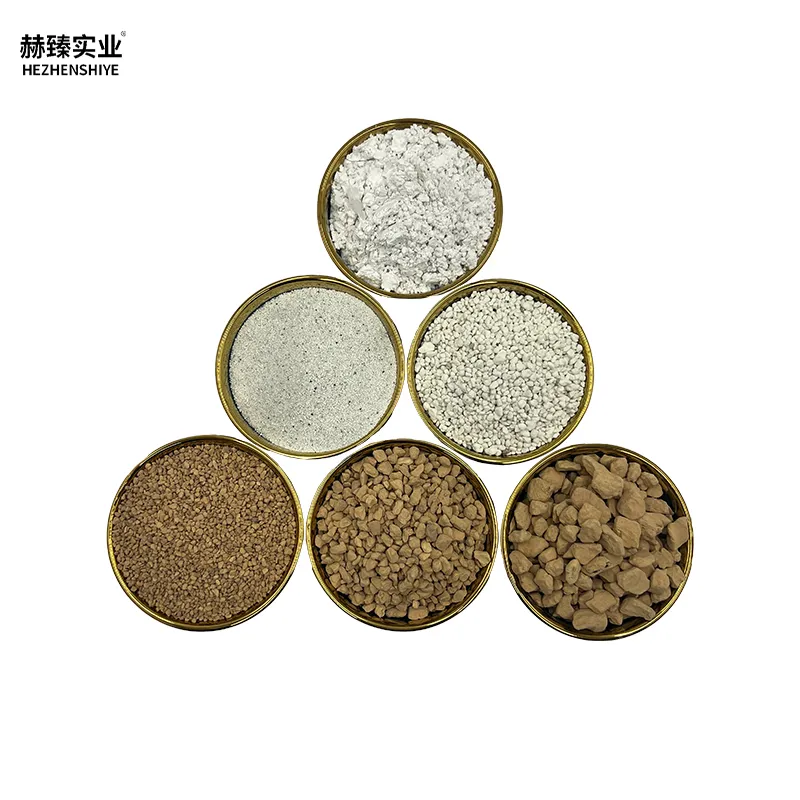

Technological advancements in material science and processing are enabling the production of diatomite with tailored properties, moving beyond its traditional uses as a filter aid to highly engineered solutions. For instance, the demand for effective and eco-friendly methods to remove heavy metals, organic pollutants, and pharmaceuticals from industrial effluents is creating a substantial market for advanced adsorbents. Conventional methods often involve high operational costs, secondary pollution, or limited efficacy against complex contaminant matrices. Diatomite, with its high surface area and unique pore structure, offers a cost-effective and environmentally benign alternative. Furthermore, the burgeoning indoor farming and hydroponics sectors necessitate substrates that optimize water retention, aeration, and nutrient availability for plants, making horticultural-grade diatomite a prime candidate. In the ceramic domain, the push for lighter, stronger, and more insulating materials, coupled with a desire for reduced firing temperatures, means that finely processed diatomite can serve as a valuable flux, filler, or porosity agent. Hezhen Industrial, through its meticulous production of Hezhen Industrial grade diatomite particles for adsorption of wastewater treatment in flower and plant cultivation and ceramic coatings, is strategically positioned to meet these multifaceted industry requirements, providing solutions that not only address immediate technical challenges but also contribute to long-term sustainability objectives. The increasing global awareness of water scarcity and pollution, coupled with the drive for higher agricultural yields and advanced material performance, underscores the critical and expanding role of specialized diatomite products in the industrial economy.

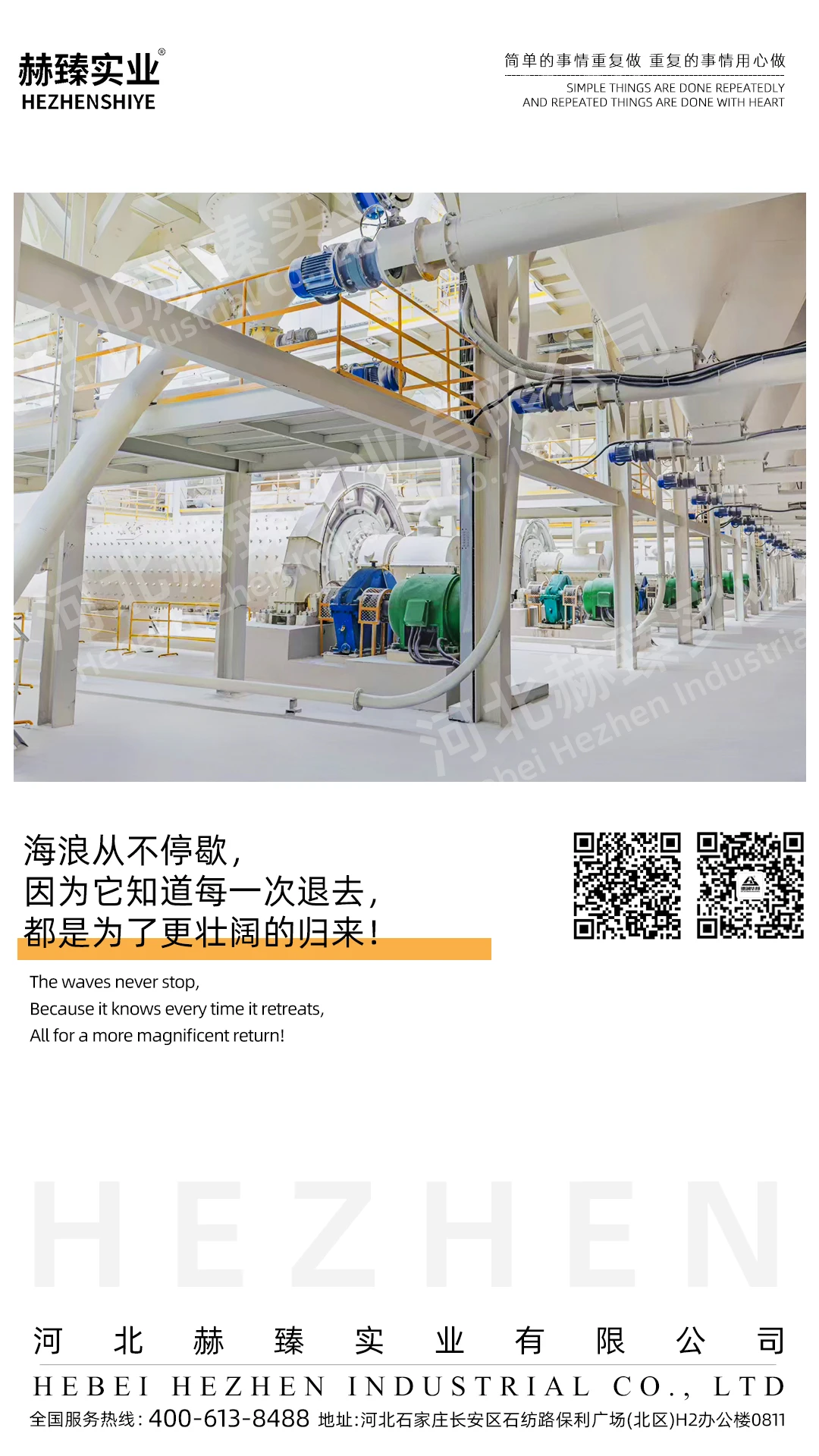

The Advanced Manufacturing Process of Hezhen Industrial Grade Diatomite Particles

The production of high-quality, industrial-grade diatomite particles, specifically those tailored for diverse applications such as wastewater treatment, horticultural cultivation, and ceramic coatings, is a sophisticated process that transcends simple quarrying. It involves a series of meticulously controlled stages, from raw material extraction to final product conditioning, ensuring the optimal physical and chemical properties required for demanding industrial applications. Unlike metallic components which undergo casting or CNC machining, diatomite processing focuses on refining its natural characteristics—primarily its microporous structure and high silica content—to enhance its functional performance. The starting material is naturally occurring diatomaceous earth, composed of the fossilized remains of diatoms, microscopic single-celled algae. These fossils possess an intricate, highly porous silica structure, which is the cornerstone of diatomite's exceptional adsorptive and filtration capabilities.

The manufacturing process typically begins with the extraction of crude diatomaceous earth from pristine deposits. This raw material then undergoes primary crushing to reduce large lumps into manageable sizes, followed by drying to remove excess moisture and prevent agglomeration. The next critical stage is milling, where the material is finely ground to achieve a specific particle size distribution. This step is crucial, as particle size directly influences surface area, flow rate, and adsorption kinetics, which are vital for efficient wastewater treatment and optimal plant growth media. Air classification or sedimentation techniques are often employed to separate particles by size, ensuring uniformity and consistency. For many industrial applications, especially those requiring enhanced purity and specific structural properties, the diatomite undergoes calcination. Calcination involves heating the material to high temperatures (typically between 800°C and 1200°C) in rotary kilns. This thermal treatment removes organic impurities, hardens the diatom frustules, and can alter the pore structure, increasing porosity and surface area, making it more robust and effective. Some specialized grades, particularly for filtration, may also involve flux calcination, where a fluxing agent like soda ash is added to promote agglomeration of smaller particles into larger, more permeable ones, creating a structure optimized for high flow rates and particulate removal.

Post-calcination, the material is cooled and then subjected to further milling and classification to achieve the precise particle size and purity required for its intended application. For instance, diatomite for wastewater treatment requires a specific pore size distribution to effectively adsorb heavy metals and organic pollutants, while particles for ceramic coatings need a very fine grind to ensure smooth dispersion and integration into glazes or bodies. Throughout this entire process, rigorous quality control measures are implemented. This includes regular sampling and analysis for particle size distribution (e.g., using laser diffraction), specific surface area (BET method), porosity, density, moisture content, and chemical composition (e.g., X-ray fluorescence for silica content and impurity levels). Adherence to international standards such as ISO 9001 for quality management and ISO 14001 for environmental management is paramount. While ANSI standards are more commonly associated with industrial piping and mechanical components, the principles of rigorous testing and performance validation are fully integrated into the production of Hezhen Industrial grade diatomite particles for adsorption of wastewater treatment in flower and plant cultivation and ceramic coatings. The typical lifespan of the diatomite material itself is indefinite; however, its functional efficacy in applications like adsorption or filtration diminishes over time as it becomes saturated or clogged, necessitating replacement or regeneration. These particles find widespread applicability across diverse industries, including environmental engineering (wastewater treatment), agriculture (flower and plant cultivation), and manufacturing (ceramic coatings). In wastewater treatment, its advantages include high adsorption capacity for heavy metals (e.g., lead, cadmium, arsenic), efficient removal of suspended solids, and reduction of chemical oxygen demand (COD) and biochemical oxygen demand (BOD), thereby contributing to significant energy savings by reducing the need for intensive chemical or energy-consuming processes. Its inherent chemical inertness also provides excellent corrosion resistance, making it suitable for contact with various industrial effluents. The precise control over the manufacturing process ensures that Hezhen Industrial’s diatomite particles offer superior performance, contributing to more sustainable and efficient industrial operations.

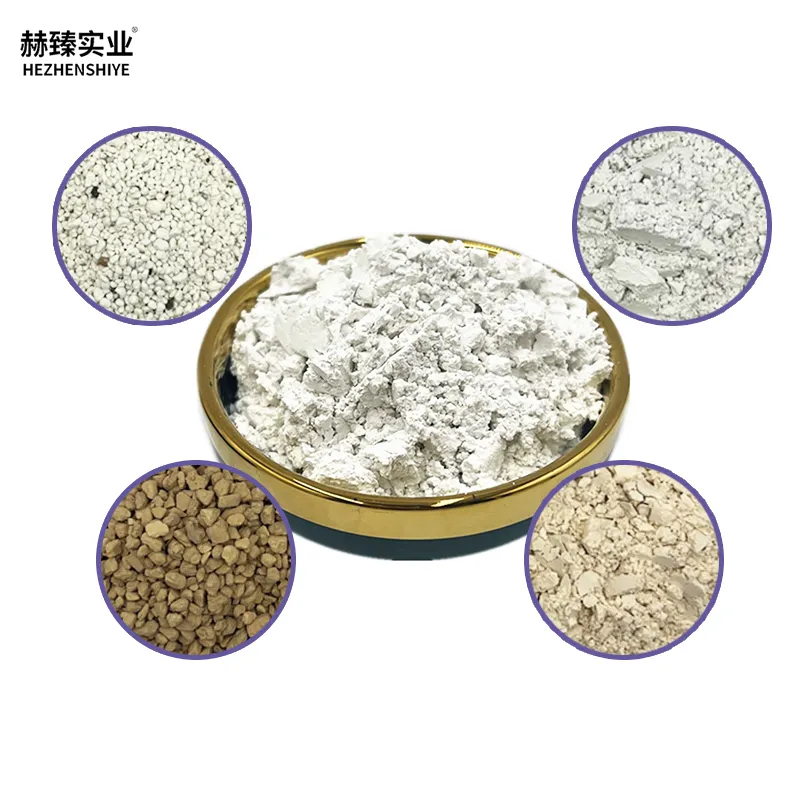

Unveiling the Technical Parameters and Superior Performance of Hezhen Diatomite Particles

The efficacy and suitability of industrial-grade diatomite particles for demanding applications such as wastewater purification, horticultural substrate enhancement, and ceramic additive integration are fundamentally determined by their precise technical parameters. Hezhen Industrial's commitment to quality ensures that its Hezhen Industrial grade diatomite particles for adsorption of wastewater treatment in flower and plant cultivation and ceramic coatings are consistently produced to stringent specifications, offering predictable and superior performance. Key parameters include particle size distribution, specific surface area, porosity, bulk density, chemical composition, and adsorption capacity, each playing a crucial role in its functional characteristics. For instance, the intricate pore structure of diatomite, derived from the natural morphology of diatom frustules, provides an incredibly high specific surface area, typically ranging from 20 to 100 m²/g depending on the processing and grade. This vast internal surface is what facilitates exceptional adsorption capabilities for heavy metals, organic compounds, and other pollutants in aqueous solutions. The microporous and mesoporous nature of the particles allows for physical adsorption (physisorption) and, in some cases, chemical adsorption (chemisorption) through surface functional groups, making it highly effective for diverse contaminant removal.

Particle size distribution (PSD) is another critical parameter, meticulously controlled to optimize performance for specific applications. For filtration in wastewater treatment, a narrower PSD can lead to more efficient cake formation and better clarity, while for adsorption, a finer particle size generally increases the available surface area for interaction with contaminants. In horticulture, an optimized PSD ensures balanced water retention and aeration, crucial for root health. The bulk density, typically ranging from 0.15 to 0.40 g/cm³, is a direct indicator of the material's porosity; lower bulk density signifies higher porosity, which is beneficial for lightweight ceramic applications and enhanced water retention in growing media. Chemically, industrial diatomite is predominantly amorphous silicon dioxide (SiO2), typically ranging from 85% to 92%, with minor impurities such as alumina, iron oxide, and alkali oxides. The low content of these impurities is vital, especially for ceramic applications where specific firing properties are desired, and for wastewater treatment where leaching of impurities must be minimized. The thermal stability of Hezhen diatomite is excellent, capable of withstanding high temperatures, which is imperative for its use in ceramic coatings where it acts as a flux or a porosity-inducing agent during high-temperature firing processes, contributing to energy efficiency by potentially lowering firing temperatures. The low thermal conductivity resulting from its porous structure also makes it an effective insulating material. Below is a comprehensive table detailing the typical technical specifications of Hezhen Industrial grade diatomite particles, demonstrating our commitment to delivering a product of consistent quality and high performance tailored to specific industrial needs.

Typical Technical Specifications for Hezhen Industrial Grade Diatomite Particles

| Parameter | Unit | Typical Value (Range) | Significance for Application |

|---|---|---|---|

| SiO2 Content (Loss-free basis) | % | 88 - 92 | High purity ensures chemical inertness and stable performance; essential for ceramic glazes and minimal leaching in water treatment. |

| Al2O3 Content | % | 2 - 4 | Minor constituent; low levels ensure minimal impact on ceramic firing characteristics and no interference in adsorption. |

| Fe2O3 Content | % | 0.5 - 1.5 | Low iron content prevents discoloration in ceramic products and ensures purity for sensitive applications. |

| Specific Surface Area (BET) | m²/g | 25 - 60 | Directly correlates with adsorption capacity for pollutants and nutrient retention in soil; higher values indicate greater active sites. |

| Median Particle Size (D50) | µm | 5 - 50 (variable by grade) | Optimized for filtration efficiency, adsorption kinetics, and flow properties in horticultural substrates or ceramic slurries. |

| Pore Volume | cm³/g | 0.8 - 1.5 | Indicates total internal volume available for adsorption and water retention; crucial for high-capacity applications. |

| Bulk Density | g/cm³ | 0.20 - 0.35 | Indicates lightweight properties; beneficial for reducing weight in ceramic applications and improving aeration in horticultural media. |

| pH (10% slurry) | - | 6.5 - 7.5 | Near-neutral pH ensures compatibility with various chemical systems and biological environments, preventing pH shocks. |

| Moisture Content | % | < 0.5 | Low moisture prevents caking, ensures free flow, and minimizes energy consumption in ceramic applications. |

| Loss on Ignition (LOI) | % | < 1.0 | Indicates minimal organic impurities, contributing to purity and stable performance at high temperatures. |

These meticulously controlled parameters ensure that Hezhen Industrial grade diatomite particles are not merely a raw material but a precision-engineered component. For wastewater treatment, the high specific surface area and optimized pore volume translate into superior adsorption rates for heavy metal ions such as Pb²⁺, Cd²⁺, Hg²⁺, and organic dyes, often achieving removal efficiencies exceeding 90% under optimized conditions. In horticultural applications, the porosity and balanced PSD lead to improved water retention (reducing irrigation needs by up to 30%), enhanced aeration for root development, and better nutrient delivery, resulting in more robust plant growth and higher yields. In ceramic coatings and bodies, the unique properties of diatomite contribute to reduced firing temperatures (potentially saving up to 15% on energy costs), improved porosity for lightweight products, enhanced thermal insulation, and improved surface finish, showcasing its versatility and profound impact across diverse industrial processes. The consistency and reliability derived from these precise specifications are key differentiators for Hezhen Industrial’s product line.

Versatile Application Scenarios for Hezhen Diatomite Particles

The exceptional physiochemical properties of Hezhen Industrial grade diatomite particles for adsorption of wastewater treatment in flower and plant cultivation and ceramic coatings position them as a highly versatile material across a myriad of industrial and agricultural applications. Its unique microporous structure, high specific surface area, chemical inertness, and thermal stability make it an ideal choice for addressing critical challenges in environmental management, sustainable agriculture, and advanced materials manufacturing. Understanding these diverse application scenarios is crucial for industrial decision-makers and technical personnel seeking optimal solutions for their operational needs.

A. Wastewater Treatment and Industrial Effluent Purification

In the realm of environmental engineering, especially wastewater treatment, Hezhen Industrial grade diatomite particles for adsorption of wastewater treatment in flower and plant cultivation and ceramic coatings play a pivotal role as an effective adsorbent and filter aid. Industrial wastewaters, originating from various sectors such as mining, textiles, petrochemicals, electroplating, and pharmaceuticals, often contain complex mixtures of pollutants, including heavy metals (e.g., cadmium, lead, chromium, copper), organic dyes, phenols, oil and grease, and suspended solids. Diatomite’s high porosity allows for excellent filtration, capturing fine suspended particles that often bypass conventional sedimentation. More critically, its vast internal surface area, rich in silanol groups (-Si-OH), provides abundant active sites for the adsorption of dissolved contaminants. Heavy metal ions can be sequestered through ion exchange, surface complexation, or precipitation mechanisms on the diatomite surface. For organic pollutants, hydrophobic interactions and van der Waals forces contribute to effective removal. Case studies demonstrate that incorporating diatomite into existing treatment systems can significantly improve effluent quality, reduce chemical coagulant consumption, and lower sludge volume. For instance, in textile wastewater treatment, Hezhen Industrial grade diatomite particles for adsorption of wastewater treatment in flower and plant cultivation and ceramic coatings have shown an average removal efficiency of 85-95% for reactive dyes, while in electroplating wastewater, heavy metal removal rates often exceed 90%. This translates into cleaner discharge, compliance with stringent environmental regulations (e.g., EPA standards, EU Water Framework Directive), and reduced operational costs associated with further treatment or penalty fees.

B. Flower and Plant Cultivation (Horticulture and Agriculture)

In horticulture and agriculture, particularly in modern cultivation techniques like hydroponics, soilless media, and container111 gardening, the physical properties of substrates are paramount for optimal plant health and yield. Hezhen Industrial grade diatomite particles for adsorption of wastewater treatment in flower and plant cultivation and ceramic coatings offer exceptional benefits as a growth medium additive or standalone substrate. Its high porosity and superior water retention capacity (holding up to 150% of its weight in water) ensure a consistent moisture supply to plant roots, reducing irrigation frequency and water consumption by 20-30%. Concurrently, its unique particle structure provides excellent aeration, preventing root rot and promoting healthy root development by facilitating oxygen exchange. Diatomite also acts as a slow-release reservoir for essential plant nutrients, adsorbing excess fertilizers and releasing them gradually as needed, minimizing nutrient leaching and improving fertilizer use efficiency. Its naturally inert and sterile nature helps in disease prevention, providing a stable and pH-neutral environment for various plant species. Furthermore, the hard, sharp edges of diatom frustules can physically deter small pests like fungus gnats and slugs, providing a natural pest control mechanism without chemical intervention. These advantages lead to more vigorous plant growth, higher yields, and reduced resource input, making it an economically and environmentally sound choice for commercial nurseries, greenhouses, and urban farms.

C. Ceramic Coatings and Material Enhancement

The ceramics industry, encompassing tiles, sanitary ware, refractories, and advanced ceramics, benefits significantly from the inclusion of specialized additives that can enhance performance characteristics and optimize manufacturing processes. Hezhen Industrial grade diatomite particles for adsorption of wastewater treatment in flower and plant cultivation and ceramic coatings serve multiple functions in ceramic formulations. As a flux, its high silica content and amorphous structure can lower the firing temperature of ceramic bodies and glazes, leading to substantial energy savings (e.g., a 5-10% reduction in firing temperature can result in 10-20% energy cost savings) and reduced production cycles. This also contributes to lower CO2 emissions, aligning with sustainability goals. As a filler, its lightweight nature contributes to the production of lighter ceramic products, which reduces transportation costs and makes handling easier. Its porous nature can be leveraged to create ceramic materials with controlled porosity, enhancing properties like thermal insulation, acoustic absorption, and water absorption. For example, in the production of insulating bricks or porous ceramics for filtration, the controlled addition of diatomite facilitates the formation of a stable, interconnected pore network. In glazes, fine diatomite particles can improve flow properties, enhance matteness or texture, and contribute to unique visual effects. The low thermal expansion coefficient of diatomite also helps reduce thermal shock susceptibility in finished ceramic products, improving durability. The high purity and consistent particle size of Hezhen’s diatomite ensure uniform dispersion within ceramic slurries and predictable firing behavior, crucial for consistent product quality.

Technical Advantages and Competitive Edge of Hezhen Diatomite Particles

In a competitive global market, the selection of raw materials is a critical determinant of product quality, operational efficiency, and environmental footprint. Hezhen Industrial grade diatomite particles for adsorption of wastewater treatment in flower and plant cultivation and ceramic coatings offer a distinct array of technical advantages that set them apart from conventional alternatives and contribute significantly to superior performance across various industrial applications. These advantages stem from our meticulous sourcing of high-purity diatomaceous earth, coupled with advanced processing technologies that optimize the inherent properties of this unique mineral.

A. Superior Adsorption and Filtration Efficiency

The primary technical advantage of Hezhen diatomite lies in its unparalleled microporous structure and high specific surface area, which are critical for both adsorption and filtration. Unlike activated carbon, which typically relies on a carbonaceous matrix, diatomite's silica-based framework provides excellent chemical stability and a different set of surface chemistries. Its highly intricate network of pores allows for exceptional capture of colloidal particles, suspended solids, and microorganisms in filtration processes, leading to superior clarity in treated water. For adsorption, the silanol groups on the surface of the Hezhen Industrial grade diatomite particles for adsorption of wastewater treatment in flower and plant cultivation and ceramic coatings facilitate strong interactions with various pollutants, including heavy metal ions (e.g., Cr(VI), Cu(II), Ni(II)) via electrostatic attraction, ion exchange, and surface complexation, as well as organic dyes and pesticides through physisorption. Laboratory tests and pilot studies have shown that Hezhen diatomite can achieve heavy metal removal rates often exceeding 95%, outperforming many conventional inorganic adsorbents in terms of capacity and kinetics, especially for dilute solutions. This high efficiency translates into smaller treatment footprints, reduced chemical consumption, and lower operational costs for wastewater treatment facilities.

B. Optimized Horticultural Performance

For agricultural and horticultural applications, the physical structure of Hezhen Industrial grade diatomite particles for adsorption of wastewater treatment in flower and plant cultivation and ceramic coatings provides multifaceted benefits. Its unique pore system allows for both excellent water retention and superior aeration, a combination rarely found in single-component growing media. Diatomite can hold approximately 100-150% of its weight in water, releasing it gradually to plant roots, thereby significantly reducing irrigation frequency and water wastage—a crucial advantage in water-stressed regions. Simultaneously, its rigid, non-compacting particle structure ensures optimal pore space for oxygen diffusion to the roots, preventing anaerobic conditions that can lead to root rot. This balanced water-to-air ratio promotes robust root development, nutrient uptake efficiency, and overall plant vigor. Furthermore, the inert nature of diatomite ensures it does not alter soil pH significantly, providing a stable growing environment. Its inorganic composition also prevents decomposition, offering a long-lasting, reusable growing medium component, unlike organic alternatives that degrade over time. These properties contribute to healthier plants, higher yields, and reduced resource input, enhancing the sustainability of cultivation practices.

C. Energy Efficiency and Material Enhancement in Ceramics

In the ceramic industry, the inclusion of Hezhen diatomite particles brings substantial process and product enhancements. As a fluxing agent, the high amorphous silica content of Hezhen Industrial grade diatomite particles for adsorption of wastewater treatment in flower and plant cultivation and ceramic coatings facilitates vitrification at lower firing temperatures. This translates directly into significant energy savings (estimated 10-20% reduction in fuel consumption) and shorter firing cycles, increasing kiln throughput and reducing production costs. Moreover, the lightweight and porous nature of diatomite enables the production of ceramics with reduced density, making handling and transportation more economical. This is particularly beneficial for products like lightweight insulating bricks, where diatomite can improve thermal insulation properties by up to 30%, making them ideal for high-temperature applications. When incorporated into glazes, fine diatomite particles can improve adherence, reduce crazing, and create unique textures or matte finishes. The consistency in particle size and chemical purity of Hezhen diatomite ensures predictable behavior during firing, leading to consistent product quality and reduced rejects.

D. Environmental and Economic Benefits

Beyond specific technical functions, the use of Hezhen Industrial grade diatomite particles for adsorption of wastewater treatment in flower and plant cultivation and ceramic coatings offers considerable environmental and economic benefits. Its natural origin and minimal processing (compared to synthetic alternatives) make it an eco-friendly choice. In wastewater treatment, its efficacy reduces reliance on more aggressive chemical treatments, minimizing sludge generation and secondary pollution. In agriculture, it promotes water conservation and reduces fertilizer runoff. In ceramics, it contributes to lower energy consumption and reduced carbon footprint. Economically, its high performance-to-cost ratio provides a compelling value proposition. While initial costs might be comparable to some alternatives, the long-term savings in operational expenses (energy, water, chemicals, disposal) and improved product quality offer a strong return on investment. Hezhen Industrial's commitment to quality assurance, including ISO 9001 certification, ensures that our clients receive a consistent, high-performance product, fostering trust and long-term partnerships.

Manufacturer Comparison: Why Hezhen Industrial Stands Apart

In the highly specialized market of industrial minerals, particularly for functional fillers and adsorbents like diatomite, discerning buyers face a multitude of choices. While numerous manufacturers offer diatomaceous earth products, the critical distinction lies in the quality, consistency, and application-specific engineering of the particles. Hezhen Industrial has strategically positioned itself as a leader in providing Hezhen Industrial grade diatomite particles for adsorption of wastewater treatment in flower and plant cultivation and ceramic coatings that not only meet but often exceed industry benchmarks. This differentiation is rooted in our comprehensive approach to raw material sourcing, advanced processing technologies, rigorous quality control, and an unwavering commitment to customer-centric solutions.

Many general-purpose diatomite suppliers offer a "one-size-fits-all" product, primarily focused on basic filtration applications. While this might suffice for less demanding uses, it falls short for sophisticated requirements in wastewater treatment, precision horticulture, or advanced ceramic formulations where specific particle size distributions, surface chemistries, and purity levels are paramount. Hezhen Industrial, by contrast, employs state-of-the-art beneficiation and calcination processes, alongside sophisticated classification techniques, to produce tailored grades of diatomite. For example, our process for Hezhen Industrial grade diatomite particles for adsorption of wastewater treatment in flower and plant cultivation and ceramic coatings ensures a meticulously controlled particle size range (often with a D50 deviation of less than 5%), which is critical for consistent flow rates in filter systems and uniform dispersion in ceramic slurries. This level of control is often absent in less specialized operations, leading to inconsistent performance and potential operational inefficiencies for end-users.

Comparative Analysis: Hezhen Industrial vs. General Diatomite Suppliers

| Feature | Hezhen Industrial Grade Diatomite | Typical General-Purpose Diatomite |

|---|---|---|

| Raw Material Source | High-purity, naturally occurring deposits with consistent geological characteristics. | Variable sources, potentially with higher impurity levels. |

| Processing Technology | Advanced milling, calcination (controlled temperature/atmosphere), and multi-stage air classification for precise PSD. | Basic crushing, drying, and single-stage grinding; less control over particle properties. |

| Particle Size Distribution (PSD) | Extremely tight and consistent, optimized for specific applications (e.g., D50 ±5% tolerance). | Broader and less consistent PSD, leading to variability in filtration rates or adsorption kinetics. |

| Specific Surface Area (BET) | Higher and precisely controlled (25-60 m²/g), maximizing active sites for adsorption. | Lower and less consistent, resulting in reduced adsorption capacity. |

| Purity (SiO2 content) | Superior purity (typically >88% SiO2), low impurity levels (Fe2O3, Al2O3). | Lower SiO2 content, higher impurities impacting performance and color. |

| Application Specificity | Engineered grades specifically for wastewater treatment, horticulture, and ceramic coatings. | General-purpose, requiring end-user to adapt or accept suboptimal performance. |

| Quality Assurance | Rigorous multi-stage QC, ISO certified processes, comprehensive batch testing. | Basic or intermittent QC, potentially non-certified processes. |

| Technical Support & Customization | Dedicated technical team, R&D capabilities, highly responsive to custom solution requests. | Limited or no technical support, minimal customization options. |

Beyond these technical specifications, Hezhen Industrial differentiates itself through its comprehensive customer support and problem-solving approach. Our team of experts understands the intricate demands of wastewater treatment plants, horticultural enterprises, and ceramic manufacturers. We don't just supply material; we provide solutions. For example, in a challenging wastewater scenario involving multiple heavy metals, our technical team can recommend the optimal grade of Hezhen Industrial grade diatomite particles for adsorption of wastewater treatment in flower and plant cultivation and ceramic coatings with specific surface modifications if needed, and assist with pilot testing to validate performance. Similarly, for ceramic applications, we work closely with R&D departments to fine-tune particle characteristics for desired firing profiles and end-product properties. This collaborative approach, combined with our robust supply chain and adherence to international quality standards, provides unparalleled reliability and value, solidifying Hezhen Industrial's reputation as a preferred partner over less specialized or commodity suppliers. Our commitment to continuous improvement and innovation ensures that our diatomite products evolve with the ever-changing demands of modern industries, guaranteeing long-term relevance and effectiveness for our clients.

Tailored Solutions: Customization and Partnership with Hezhen Industrial

Recognizing that no two industrial applications are exactly alike, Hezhen Industrial places a strong emphasis on offering customized solutions to meet the precise requirements of our clients. While our standard range of Hezhen Industrial grade diatomite particles for adsorption of wastewater treatment in flower and plant cultivation and ceramic coatings covers a broad spectrum of needs, certain niche applications or unique operational challenges necessitate a tailored approach. Our in-house research and development capabilities, coupled with our advanced manufacturing flexibility, enable us to engineer diatomite particles with specific properties that optimize performance for even the most demanding scenarios. This commitment to customization ensures that our clients receive a product that is not just suitable, but perfectly optimized for their specific process.

Customization can manifest in several key areas. Firstly, particle size distribution is often fine-tuned. For a wastewater treatment plant struggling with ultra-fine suspended solids, we can produce diatomite with a tighter distribution of smaller particles to enhance filter cake formation and clarity. Conversely, for high-flow rate applications, a coarser grade might be developed to reduce pressure drop while maintaining filtration efficiency. Secondly, the specific surface area and porosity can be adjusted through precise calcination parameters and post-processing techniques. Higher surface areas might be achieved for applications demanding maximum adsorption capacity for trace contaminants, while specific pore size distributions can be engineered to selectively adsorb certain molecular sizes. For instance, in horticultural applications where specific water retention and aeration profiles are desired for particular plant species or hydroponic systems, we can modify the pore structure of the Hezhen Industrial grade diatomite particles for adsorption of wastewater treatment in flower and plant cultivation and ceramic coatings to meet those precise needs. Thirdly, while the core chemical composition remains consistent, minor modifications or surface treatments can be explored to enhance specific functionalities. For example, surface functionalization might be considered to improve selective adsorption of certain heavy metals or to enhance compatibility with specific organic binders in ceramic applications, though this is less common for general industrial diatomite.

The customization process at Hezhen Industrial begins with a detailed consultation to understand the client's specific application, current challenges, desired performance metrics, and existing operational parameters. Our technical sales engineers, backed by R&D specialists, collaborate closely with the client's technical team. This involves analyzing sample materials (e.g., wastewater effluents, soil samples, ceramic slurries), conducting laboratory-scale trials using various diatomite grades, and developing pilot-scale demonstrations if necessary. We leverage our expertise in mineral processing and material science to propose a customized solution, which may involve modifying particle size, optimizing surface properties, or adjusting bulk density to meet the precise demands. This iterative process ensures that the developed Hezhen Industrial grade diatomite particles for adsorption of wastewater treatment in flower and plant cultivation and ceramic coatings truly addresses the client's unique requirements, leading to enhanced performance, greater efficiency, and often, significant cost savings in the long run. Our agility in production and commitment to research mean we are capable of delivering custom batches, ensuring scalability from pilot to full commercial production. This partnership approach, rather than a mere transactional one, is a cornerstone of Hezhen Industrial's value proposition, building enduring relationships based on trust, technical excellence, and mutual success.

Proven Success: Application Cases and Client Testimonials

The true measure of any industrial product lies in its real-world performance and the tangible benefits it delivers to end-users. Hezhen Industrial is proud to showcase a strong portfolio of successful application cases where Hezhen Industrial grade diatomite particles for adsorption of wastewater treatment in flower and plant cultivation and ceramic coatings have significantly improved processes, reduced costs, and enhanced environmental compliance for our clients across various sectors. These case studies underscore our expertise, the product's versatility, and our commitment to delivering tangible results.

Case Study 1: Heavy Metal Removal in Electroplating Wastewater

A prominent electroplating facility in Southeast Asia faced persistent challenges in meeting stringent discharge limits for heavy metals, particularly nickel and copper. Their existing chemical precipitation system was costly, generated large volumes of toxic sludge, and still occasionally exceeded permissible limits. After a comprehensive assessment by Hezhen Industrial's technical team, a pilot-scale adsorption unit utilizing Hezhen Industrial grade diatomite particles for adsorption of wastewater treatment in flower and plant cultivation and ceramic coatings was implemented as a tertiary treatment step. The optimized grade of diatomite, selected for its high specific surface area and engineered pore structure, demonstrated remarkable performance. Over a six-month trial period, the average removal efficiency for nickel increased from 80% to over 98%, and for copper, from 85% to 99.5%. This success enabled the facility to consistently meet local regulatory standards, significantly reduce the volume of hazardous sludge requiring disposal by 30%, and decrease their overall chemical consumption by 15%, leading to an estimated annual saving of $75,000.

Client Feedback: "The integration of Hezhen's diatomite has been a game-changer for our wastewater treatment plant. Not only have we achieved compliance with ease, but the operational savings have been substantial. The technical support from Hezhen throughout the process was exemplary." - Environmental Manager, Large Electroplating Company.

Case Study 2: Enhancing Yields in Commercial Hydroponic Farm

A major commercial hydroponic lettuce farm in Europe sought to optimize its growing media for improved yields and reduced water consumption. Their existing rockwool substrates, while effective, were prone to waterlogging in certain sections and required frequent irrigation. Hezhen Industrial proposed incorporating Hezhen Industrial grade diatomite particles for adsorption of wastewater treatment in flower and plant cultivation and ceramic coatings as a 20% amendment to their existing substrate mix. The results were compelling: The porous nature of the diatomite provided a superior balance of water retention and aeration, leading to a 25% reduction in irrigation frequency while maintaining optimal moisture levels. Furthermore, the enhanced aeration promoted healthier root systems, which translated into a 12% increase in average lettuce head weight and a 7% reduction in crop cycle time. The farm also noted a significant decrease in instances of root rot, underscoring the improved growing environment facilitated by the diatomite.

Client Feedback: "Hezhen's diatomite has proven to be an invaluable addition to our hydroponic system. Our plants are healthier, yields are up, and we're saving a considerable amount of water. It's a sustainable solution that delivers clear economic benefits." - Head Agronomist, European Hydroponics.

Case Study 3: Energy Savings in Ceramic Tile Manufacturing

A large-scale ceramic tile manufacturer was looking to reduce energy consumption in their kilns and improve the whiteness of their porcelain tiles. Traditional feldspar-based fluxes required high firing temperatures. After consultation, Hezhen Industrial recommended a specialized, finely ground Hezhen Industrial grade diatomite particles for adsorption of wastewater treatment in flower and plant cultivation and ceramic coatings to be incorporated as a partial replacement for existing flux materials. The unique amorphous silica structure of Hezhen diatomite acted as an effective flux, allowing the manufacturer to reduce their firing temperature by 50°C (from 1200°C to 1150°C) without compromising the tile's mechanical strength or aesthetic appeal. This temperature reduction resulted in an immediate 18% saving in natural gas consumption in the kilns. Additionally, the high purity of the diatomite contributed to a brighter, whiter fired body, reducing the need for expensive opacifiers in the glaze. The consistent particle size ensured smooth processing and minimal defects.

Client Feedback: "The energy savings alone justify the switch to Hezhen diatomite. We're producing higher quality tiles at a lower cost, and our carbon footprint has noticeably decreased. Hezhen Industrial has truly proven their expertise in ceramic materials." - Production Director, Leading Ceramic Tile Manufacturer.

Ensuring Trust: FAQs, Delivery, Warranty & Customer Support

At Hezhen Industrial, we understand that establishing trust is paramount in B2B relationships. Beyond the technical excellence of our Hezhen Industrial grade diatomite particles for adsorption of wastewater treatment in flower and plant cultivation and ceramic coatings, we are committed to providing transparent, reliable, and responsive service. This section addresses common inquiries and outlines our robust support framework, designed to give our clients complete confidence in partnering with us.

Frequently Asked Questions (FAQs)

- Q1: What makes Hezhen diatomite "industrial grade" compared to other types?

A1: Our industrial-grade diatomite undergoes specific processing, including precise particle size classification, calcination at controlled temperatures, and stringent quality control, to ensure consistent purity, high specific surface area, and optimized pore structure. This makes Hezhen Industrial grade diatomite particles for adsorption of wastewater treatment in flower and plant cultivation and ceramic coatings superior for demanding applications in water treatment, advanced horticulture, and ceramic manufacturing, where standard food or feed grade diatomite may not meet the performance requirements. - Q2: Is Hezhen diatomite safe for use in horticultural applications and does it contain crystalline silica?

A2: Our diatomite for horticultural applications is primarily amorphous silica. While all natural diatomaceous earth contains trace amounts of naturally occurring crystalline silica, our processing and grading ensure levels are well below safety thresholds for handling and application. For specific grades used in human or animal contact, we provide full safety data sheets (SDS) and certifications. Our product for plant cultivation is non-toxic and environmentally benign, improving soil health and plant vitality. - Q3: How does Hezhen diatomite compare to activated carbon for wastewater adsorption?

A3: While activated carbon is effective for a broad range of organic pollutants, Hezhen Industrial grade diatomite particles for adsorption of wastewater treatment in flower and plant cultivation and ceramic coatings offer unique advantages. Diatomite is particularly effective for heavy metal removal through different adsorption mechanisms and is often more cost-effective for high-volume applications. Its filtration capabilities also surpass activated carbon. In many cases, a combination of diatomite and activated carbon can provide a synergistic and highly efficient treatment solution. - Q4: Can Hezhen diatomite be customized for specific ceramic firing temperatures or glaze properties?

A4: Absolutely. We specialize in providing customized solutions. Our R&D team can work with your ceramic engineers to develop a tailored grade of Hezhen Industrial grade diatomite particles for adsorption of wastewater treatment in flower and plant cultivation and ceramic coatings that meets your specific firing temperature reduction targets, improves product porosity, or contributes to desired glaze aesthetics (e.g., matte finish, specific texture). - Q5: What are the typical lead times for large-volume orders?

A5: Our standard lead time for most common grades is typically 2-4 weeks, depending on order size and destination. For customized grades or exceptionally large volumes, we will provide a precise lead time estimate during the quotation process, factoring in raw material availability and production scheduling. We maintain robust inventory levels and efficient logistics to ensure timely delivery.

Delivery Cycle and Logistics

Hezhen Industrial is committed to efficient and reliable delivery of Hezhen Industrial grade diatomite particles for adsorption of wastewater treatment in flower and plant cultivation and ceramic coatings. Our logistics team works diligently to ensure that your orders are processed and shipped promptly, minimizing downtime for your operations. We offer flexible packaging options, including bulk bags (super sacks), paper bags, or customized packaging, to suit your handling and storage requirements. We leverage a network of trusted freight partners to provide competitive shipping rates and ensure secure transit, whether by sea, rail, or truck. For international shipments, we manage all necessary documentation and customs procedures to facilitate a smooth import process. Customers can track their orders through our dedicated customer portal or by contacting their assigned account manager for real-time updates.

Quality Assurance and Warranty Commitment

Hezhen Industrial stands by the superior quality of its products. Each batch of Hezhen Industrial grade diatomite particles for adsorption of wastewater treatment in flower and plant cultivation and ceramic coatings undergoes rigorous multi-stage quality control, adhering to our ISO 9001 certified quality management system. This includes comprehensive testing for particle size distribution, specific surface area, chemical composition, and other relevant parameters as per product specifications. We provide a Certificate of Analysis (CoA) with every shipment, verifying that the product meets or exceeds the stated technical specifications. Our warranty guarantees that our products are free from defects in material and workmanship and conform to the agreed-upon specifications at the time of delivery. In the rare event of a product not meeting these standards, Hezhen Industrial commits to prompt investigation, replacement, or appropriate compensation, demonstrating our unwavering dedication to customer satisfaction and product reliability.

Dedicated Customer Support

Our commitment to our clients extends far beyond product delivery. Hezhen Industrial provides comprehensive customer support, ensuring you have access to expert assistance whenever needed. Our dedicated account managers serve as your primary point of contact, providing personalized service, order updates, and technical guidance. Our technical support team, composed of seasoned material scientists and application engineers, is available to assist with product selection, troubleshoot application-specific challenges, and offer insights into optimizing performance. Whether you need assistance with integrating Hezhen Industrial grade diatomite particles for adsorption of wastewater treatment in flower and plant cultivation and ceramic coatings into a new process, troubleshooting an existing system, or exploring innovative applications, our experts are ready to provide timely and knowledgeable support. We believe that strong, ongoing support is crucial for fostering long-term partnerships and ensuring the continued success of our clients.

Authoritative References and Further Reading

The information presented herein regarding Hezhen Industrial grade diatomite particles for adsorption of wastewater treatment in flower and plant cultivation and ceramic coatings is supported by extensive research, industry best practices, and scientific literature. For those seeking deeper insights into the properties and applications of diatomite, we recommend consulting the following authoritative sources and academic publications:

- Water Treatment & Adsorption:

- Al-Ghouti, M. A., & Al-Degs, D. A. (2009). Diatomite as an Adsorbent for Industrial Wastewater Treatment: A Review. Desalination and Water Treatment, 8(1-3), 209-224. Link to Abstract

- Mane, V. V., & Deo, G. (2009). Synthesis of mesoporous silica from diatomaceous earth and its use as an adsorbent for lead(II) and copper(II) ions. Journal of Hazardous Materials, 172(2-3), 1318-1325. Link to ScienceDirect

- Horticulture & Agriculture:

- Liang, Y., & Rengel, Z. (2008). Diatomaceous earth as a soil amendment for improving crop growth and nutrient uptake. Journal of Plant Nutrition, 31(1), 163-176. Link to Taylor & Francis Online

- Casey, P., & Dindal, R. L. (2008). Diatomaceous earth: Biological activities and human health effects. Environmental Science & Technology, 42(1), 3-10. (This reference broadly covers DE's properties and effects.) Link to ACS Publications

- Ceramic Coatings & Materials:

- Zamani, C., & Ghoreishi, M. (2014). The effect of diatomite on the properties of ceramic bodies. Ceramics International, 40(6), 7957-7963. Link to ScienceDirect

- Shao, H., Ding, S., & Wu, C. (2018). Preparation and properties of porous ceramics from diatomite and clay. Materials Letters, 218, 194-197. Link to ScienceDirect

- General Diatomite Properties & Processing:

- International Diatomite Producers Association (IDPA) - Industry White Papers and Best Practices. Link to IDPA Website

These references, among many others, validate the scientific principles behind the efficacy of Hezhen Industrial grade diatomite particles for adsorption of wastewater treatment in flower and plant cultivation and ceramic coatings and underscore its growing importance in sustainable industrial practices. Hezhen Industrial is committed to leveraging the latest scientific advancements to continually enhance our products and solutions.