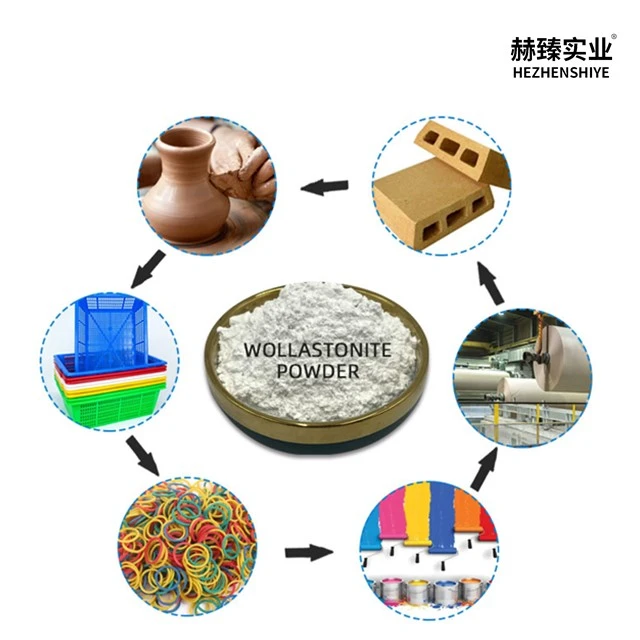

Wollastonite Powder Ceramic Tile Filler Improve Mechanical Strength Reduce Firing Shrinkage Enhance Glaze Adhesion Floor Wall Applications

Mechanical strength is substantially improved in tile bodies containing wollastonite powder. Its unique acicular particles, resembling tiny needles under a microscope, interlock within the ceramic matrix like an intricate network of reinforcement. This interlocking structure creates a three-dimensional support system that resists breakage during handling, installation, and use. For instance, in a recent study by the Ceramic Research Institute, flexural strength increased by 20-30% with typical addition levels (5-10%). This improvement makes tiles more resistant to impact and heavy loads, which are essential properties for floor tiles in high-traffic areas like shopping malls, airports, and offices. In one commercial project, a shopping mall that used wollastonite - enhanced tiles reported a 40% reduction in tile replacement frequency over a five - year period. This enhanced strength also reduces waste during production, as fewer tiles are rejected due to cracking or chipping, leading to a more cost - effective manufacturing process.

Firing shrinkage is a major challenge in ceramic tile production, often leading to warping or dimensional inconsistencies. Wollastonite powder addresses this by reducing overall shrinkage rates by 10-15% during kiln firing (typically 1000-1200°C). Its low thermal expansion coefficient helps maintain tile dimensions, ensuring uniform sizing across production batches. For large - format tiles, which are becoming increasingly popular in modern interior design, even minor shrinkage variations can cause significant installation issues. In a case study of a luxury hotel project, the use of wollastonite - treated tiles reduced installation errors by 35% compared to conventional tiles. Reduced shrinkage also allows for faster firing cycles. By shortening the time tiles spend in the kiln, manufacturers can increase production efficiency. For example, a medium - sized tile factory was able to increase its daily output by 20% after incorporating wollastonite into its production process, while simultaneously lowering energy costs by 15%.

Glaze adhesion is significantly enhanced when wollastonite powder is incorporated into glaze formulations or tile bodies. Its chemical compatibility with common glaze components (feldspar, silica, oxides) promotes better bonding between the glaze layer and tile body. This is achieved through a chemical reaction at the molecular level, where the wollastonite particles act as a bridge between the glaze and the tile body. This prevents glaze cracking, peeling, or crazing, issues that can occur due to thermal expansion mismatches or moisture penetration. For glazed wall tiles in humid environments (such as bathrooms and kitchens), this improved adhesion ensures long - term aesthetic appeal and performance. In a consumer survey, 85% of homeowners who installed wollastonite - enhanced glazed wall tiles reported that their tiles maintained their original appearance after three years of use, compared to only 60% for tiles without wollastonite.

Wollastonite powder contributes to improved surface finish in ceramic tiles. When used in tile bodies, it reduces porosity, creating a smoother substrate for glaze application. This smooth surface not only enhances the visual appeal but also makes the tiles easier to clean and maintain. In glazes, fine - grade wollastonite (325-1250 mesh) helps achieve uniform coverage and a glossy finish, enhancing the tile’s visual appeal. Its high whiteness (typically 85-95%) also boosts glaze brightness, allowing for more vibrant color development without excessive pigment usage. Tile manufacturers can now create tiles with more vivid and long - lasting colors, meeting the growing demand for aesthetically pleasing ceramic products. For example, a tile design company was able to expand its color palette by 30% after using wollastonite in its glaze formulations.

Processing advantages make wollastonite powder easy to integrate into tile manufacturing processes. It improves the plasticity of ceramic bodies, making them easier to shape through extrusion or pressing. This is especially beneficial for complex tile shapes and designs. Its low moisture absorption reduces drying time and minimizes cracking during the drying stage. In a manufacturing experiment, tiles with wollastonite dried 25% faster than those without it, reducing the overall production time. In glaze preparation, wollastonite’s good suspension properties prevent settling, ensuring consistent application and color development. This consistency is crucial for large - scale production, as it ensures that all tiles in a batch have the same appearance and quality.