Calcium Carbonate Powder stands as a core and indispensable component in diverse construction materials, exerting a profound and irreplaceable role in boosting the overall performance of these materials across multiple dimensions. The construction industry, as a cornerstone of global development, has long been in pursuit of materials that strike a perfect balance between exceptional durability and economic cost-effectiveness, and calcium carbonate powder emerges as a standout solution that impeccably fulfills these dual demands. When integrated into concrete, a fundamental material in construction, calcium carbonate powder meticulously adjusts the particle size distribution of the concrete mixture. This adjustment is not merely superficial; it optimizes the packing density of solid particles within the mixture, effectively minimizing voids between aggregates and cement particles. The resultant compact structure not only substantially enhances the compressive strength of the concrete—enabling it to bear heavier loads in structures like high-rise buildings and large-span bridges—but also drastically reduces permeability. This reduced permeability acts as a robust barrier, preventing water, chloride ions, and other harmful chemical substances from seeping into the concrete matrix. Over extended periods, such seepage often leads to internal corrosion of steel reinforcements and degradation of the concrete itself. By inhibiting this process, calcium carbonate powder significantly extends the service life of buildings and structures. Consequently, the frequency of maintenance, repairs, and even full-scale reconstructions is markedly reduced, translating to substantial savings in both economic resources and labor inputs for construction projects.

In the production of various wall materials, ranging from widely used cement bricks to high-performance autoclaved aerated concrete blocks that are gaining popularity in modern construction, calcium carbonate powder assumes the role of a critical additive with precise regulatory functions. It plays a key part in fine-tuning the setting time of raw material mixtures, a factor that directly influences the production efficiency and final quality of wall materials. By controlling the setting rate, calcium carbonate powder ensures that the wall materials form a uniform internal structure during curing, free from defects such as internal cracks or uneven density. This uniform structure in turn endows the wall materials with excellent mechanical properties, including sufficient flexural strength and impact resistance, making them capable of withstanding external forces encountered during transportation and construction. A notable advantage of wall materials incorporating an appropriate proportion of calcium carbonate powder is their reduced weight compared to traditional wall materials that lack this additive. This lightweight characteristic does not come at the expense of strength; instead, it achieves a harmonious combination of lightness and sturdiness. For construction projects, this translates to a significant reduction in the load borne by building foundations. Lighter wall materials mean that foundation designs can be more optimized, reducing the amount of concrete and steel used in foundation construction, which in turn cuts down on project costs. Furthermore, the lightweight feature simplifies the entire transportation and construction process. During transportation, more wall materials can be loaded per trip, lowering transportation costs and reducing carbon emissions associated with logistics. On construction sites, workers can handle and install the lighter materials more easily and efficiently, shortening the construction period and improving overall work productivity.

Sustainable development has evolved into a core and non-negotiable focus in the global construction industry, as the sector strives to minimize its environmental footprint while meeting the growing demand for infrastructure. In this context, calcium carbonate powder makes a substantial and multifaceted contribution to advancing this overarching goal. As a naturally occurring mineral, calcium carbonate is widely distributed and abundant across the globe, with reserves that can support long-term industrial use. Unlike some rare or synthetic raw materials, its mining and processing processes generate relatively low environmental impact. Modern mining practices for calcium carbonate prioritize environmental protection, including measures such as land reclamation after mining and dust control during extraction, further mitigating any potential ecological disturbances. When compared to other industrial raw materials like certain metal ores or synthetic additives, the energy consumption and pollutant emissions associated with calcium carbonate mining and processing are significantly lower. The integration of calcium carbonate powder into construction materials also plays a pivotal role in reducing dependence on non-renewable resources. It can partially replace materials that are either scarce or require exorbitant amounts of energy to produce, such as some types of fine aggregates or specialized cementitious materials. This substitution not only conserves valuable non-renewable resources but also reduces the overall energy consumption of the construction material production chain. Additionally, construction materials infused with calcium carbonate powder exhibit superior thermal insulation performance. This attribute is particularly valuable in building construction, as it creates a more effective thermal barrier between the interior and exterior of buildings. In cold climates, this means less heat is lost from the interior to the outside, reducing the energy required for heating systems. In hot climates, it prevents excessive heat from entering the building, lowering the energy consumption of air-conditioning systems. This reduction in energy use for heating and cooling directly aligns with global efforts to achieve energy saving and emission reduction targets, helping to curb greenhouse gas emissions and combat climate change.

Urban infrastructure construction, which encompasses vital facilities such as roads, bridges, tunnels, and municipal pipelines, reaps substantial benefits from the widespread application of calcium carbonate powder. Roads, in particular, endure constant wear and tear from heavy traffic and exposure to harsh environmental conditions, and calcium carbonate powder proves to be a game-changer in enhancing their performance. Asphalt mixtures incorporating calcium carbonate powder exhibit significantly improved wear resistance, as the powder reinforces the asphalt matrix and reduces the abrasion caused by vehicle tires. Additionally, the powder enhances the anti-aging properties of the asphalt, slowing down the degradation process caused by prolonged exposure to sunlight, oxygen, and temperature fluctuations. As a result, these roads can withstand the pressure of heavy traffic loads—including large trucks and buses—and endure extreme weather conditions such as scorching high temperatures in summer and freezing cold in winter without sustaining significant damage like potholes, cracks, or surface peeling. Bridges and tunnels, which demand unparalleled structural stability to ensure public safety, rely on concrete mixed with calcium carbonate powder to enhance their durability against corrosion. Rainwater, especially in areas with high levels of air pollution, often contains acidic substances and harmful pollutants that can corrode the concrete and the underlying steel reinforcements. Calcium carbonate powder modifies the concrete's pore structure and chemical composition, creating a more corrosion-resistant barrier that prevents these harmful substances from penetrating deep into the structure. This significantly extends the service life of bridges and tunnels, reducing the need for costly maintenance and repair work. Beyond urban areas, rural renovation projects also leverage the advantages of calcium carbonate powder. In the construction of village roads, the powder enhances the durability of local road materials, allowing them to withstand the passage of agricultural vehicles and harsh rural environmental conditions. In the construction of residential houses and public facilities like village community centers and schools, calcium carbonate-infused materials improve the structural stability and thermal insulation of these buildings, enhancing the living and working conditions of rural residents. Throughout all these applications, calcium carbonate powder adheres to strict environmental protection standards, ensuring that rural development does not come at the expense of the local ecosystem.

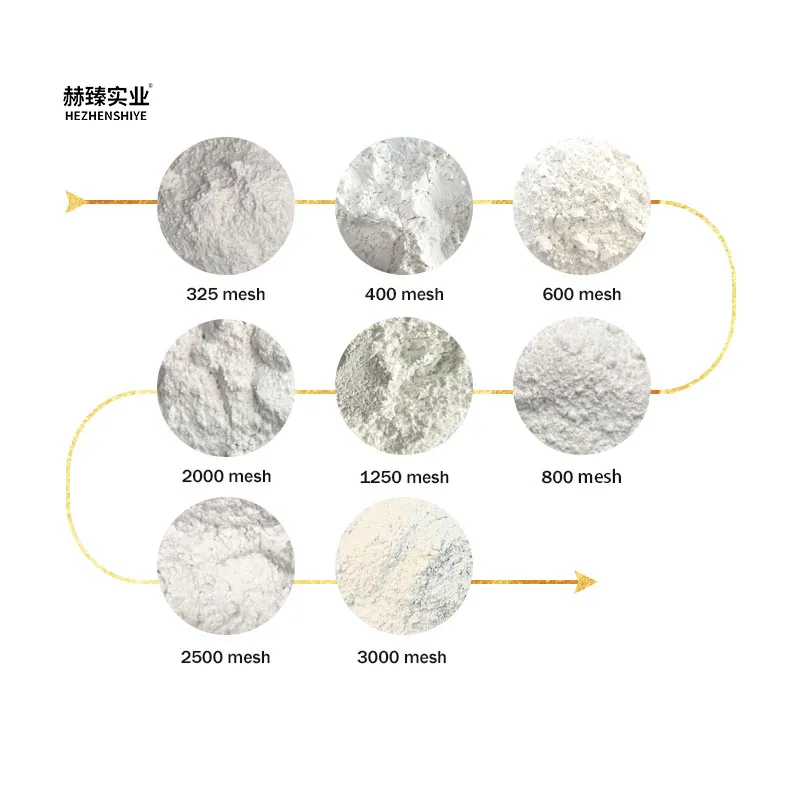

Calcium Carbonate Powder demonstrates remarkable adaptability across a wide array of construction scenarios, thanks to its adjustable properties and compatibility with different material formulations. In regions characterized by high humidity, such as tropical and subtropical areas or areas with frequent rainfall, construction materials containing calcium carbonate powder exhibit superior moisture resistance. The compact structure induced by the powder minimizes the material's water absorption rate, preventing moisture from infiltrating the interior of walls, floors, or other structures. This not only inhibits the growth of mold and mildew—common issues in humid environments that can compromise indoor air quality and material integrity—but also prevents material deterioration such as warping, swelling, or rotting, ensuring the long-term stability of the construction. In cold regions where freezing and thawing cycles are a persistent challenge, materials infused with calcium carbonate powder gain enhanced frost resistance. The powder reduces the porosity of the material, limiting the amount of water that can seep in and freeze. When water freezes, it expands, which can cause cracks in construction materials. By minimizing this water absorption and expanding space, calcium carbonate powder helps avoid cracking caused by repeated freezing and thawing cycles, making the materials suitable for use in cold northern climates and high-altitude areas. Moreover, calcium carbonate powder can be processed into a diverse range of particle sizes through specialized grinding and classification technologies, allowing it to meet the specific requirements of various construction materials. Fine-grained calcium carbonate powder, with particle sizes ranging from a few micrometers to tens of micrometers, is ideal for producing high-performance concrete used in high-rise buildings and precision engineering, as well as decorative materials like wall putty and decorative stones, where a smooth surface and uniform texture are essential. Coarse-grained calcium carbonate powder, on the other hand, is well-suited for road construction as a component of asphalt mixtures or as a filling material for foundations, where its strength and stability contribute to the overall structural integrity of the project. With the continuous advancement of processing technologies, such as the development of ultra-fine grinding and surface modification techniques, calcium carbonate powder is poised to play an even more pivotal role in the construction industry.

Banner PDF

Banner PDF Get A Quote

Get A Quote