Introduction to Advanced Photoluminescent Solutions

In modern infrastructure development, the integration of sustainable and safety-enhancing materials is paramount. This document provides a comprehensive overview of Hezhen light absorbs Luminous Stone or Glowing Pebbles, a cutting-edge photoluminescent aggregate designed for diverse industrial and public safety applications. These innovative materials offer passive illumination, significantly contributing to energy efficiency and operational safety in various demanding environments.

The demand for self-illuminating pathway solutions, such as fluorescent stone for stairs outdoor walking road decoration, has seen substantial growth. This product category addresses critical needs in urban planning, industrial safety, and aesthetic landscaping, providing durable and low-maintenance solutions for nocturnal visibility. We will explore the technical intricacies, application versatility, and strategic advantages that position Hezhen products as a leading choice in this specialized market.

Manufacturing Process: Hezhen Luminous Stone Production

The production of Hezhen light absorbs Luminous Stone or Glowing Pebbles involves a meticulously controlled multi-stage process, ensuring optimal photoluminescent performance and structural integrity. This process begins with the selection of high-purity raw materials and culminates in rigorous quality assurance testing.

1. Raw Material Sourcing and Preparation

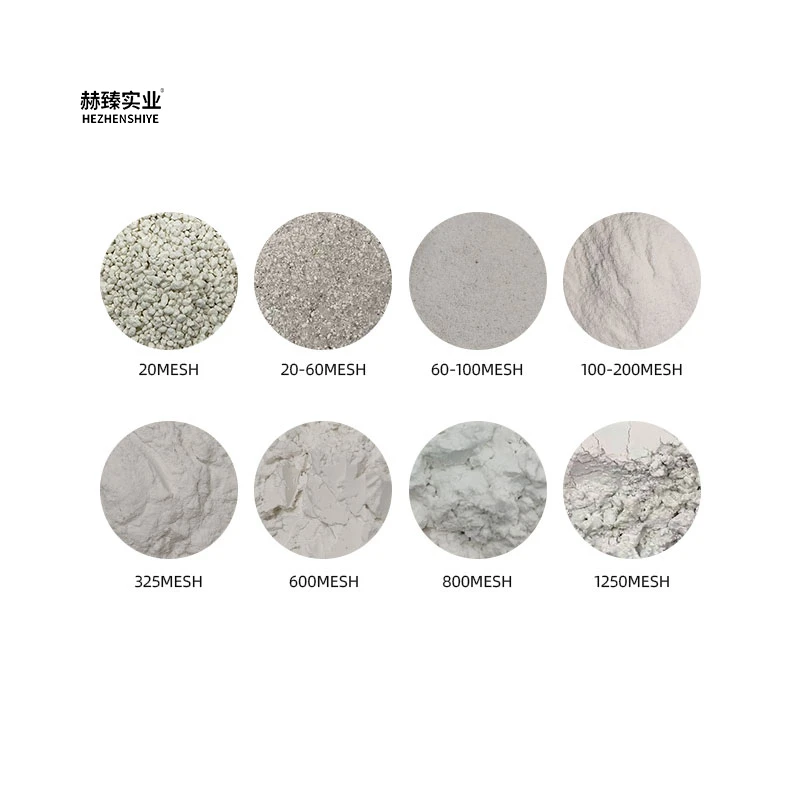

The core luminescent component is typically a strontium aluminate-based phosphor, renowned for its superior brightness and extended afterglow compared to traditional zinc sulfide-based phosphors. This is combined with high-grade, durable resins (e.g., epoxy, polyurethane, or acrylic) and inert aggregate fillers (e.g., quartz, granite dust) to form the pebble matrix. Careful particle size distribution of the phosphor is critical for uniform light emission.

2. Mixing and Dispersion

In this phase, the photoluminescent pigments are precisely blended with the chosen resin and aggregate fillers. Advanced dispersion techniques are employed to ensure homogeneous distribution of the phosphor particles throughout the resin matrix. This prevents agglomeration and maximizes the surface area exposed for light absorption and emission, directly impacting the stone's luminance intensity and consistency.

3. Forming and Curing (Casting/Molding)

The mixed material is then transferred to custom molds, typically through a casting process, to form the desired pebble shapes and sizes. This stage is crucial for achieving consistent dimensions and smooth surface finishes. The molded products undergo a controlled curing process, where the resin polymerizes and hardens, encapsulating the luminous particles within a robust, weather-resistant matrix. This process avoids high-temperature forging or CNC machining, which could degrade the photoluminescent properties of the strontium aluminate.

Image 1: Illustrating the glow of Hezhen light absorbs Luminous Stone or Glowing Pebbles in a low-light setting.

4. Finishing and Post-Processing

Once cured, the pebbles undergo finishing processes such as deburring, polishing, and surface treatment to enhance their aesthetic appeal and functional properties. Some products may receive a protective coating to further improve UV resistance, abrasion resistance, and chemical stability, extending the product's service life.

5. Quality Control and Testing Standards

Every batch of Hezhen light absorbs Luminous Stone or Glowing Pebbles undergoes stringent quality control testing. Key parameters include:

- Luminance Intensity: Measured using a photometer, typically after 10 minutes and 60 minutes following a specified charging period, adhering to standards like ASTM E2073 or DIN 67510 Part 1.

- Afterglow Duration: Quantified as the time taken for the luminance to decay to 0.32 mcd/m² (the human eye's perception threshold in dark adapted conditions).

- Physical Properties: Tests for compression strength, abrasion resistance (e.g., Taber Abrasion Test), and impact resistance.

- Environmental Stability: Accelerated weathering tests (UV exposure, freeze-thaw cycles, salt spray) to ensure long-term performance in outdoor conditions, compliant with standards such as ISO 4892-2 for artificial weathering or ASTM G154.

- Chemical Resistance: Verification against common acids, alkalis, and solvents relevant to target industries.

These meticulous testing protocols ensure that Hezhen products meet or exceed international performance benchmarks, offering an impressive service life exceeding 15-20 years in typical outdoor applications.

Industry Trends and Market Dynamics

The global market for photoluminescent materials is experiencing robust growth, driven by increasing demand for sustainable infrastructure, enhanced safety regulations, and innovative aesthetic applications. Key trends influencing the adoption of fluorescent stone for stairs outdoor walking road decoration include:

- Smart City Initiatives: Urban centers are increasingly integrating passive lighting solutions to reduce energy consumption and light pollution while maintaining public safety and navigability.

- Green Building Certifications: Materials that contribute to energy efficiency and reduce environmental impact are favored in green building projects, boosting the appeal of self-illuminating aggregates.

- Outdoor Leisure & Hospitality: Resorts, theme parks, and public gardens are leveraging luminous stones for unique ambiance creation and path delineation without relying on constant electrical power.

- Safety Enhancement: Strict safety codes in industrial, commercial, and residential sectors mandate clear egress routes and hazard markings, driving demand for reliable, non-electric lighting.

- Technological Advancements: Continuous improvements in phosphor technology lead to higher brightness, longer afterglow, and greater UV stability, making these products more viable for diverse applications.

The market is projected to expand significantly, with North America and Europe leading in adoption due to mature infrastructure and stringent safety standards, while Asia-Pacific shows rapid growth fueled by urbanization and infrastructure development.

Technical Specifications and Performance Metrics

Understanding the detailed technical specifications of Hezhen light absorbs Luminous Stone or Glowing Pebbles is critical for architects, engineers, and project managers. These parameters dictate suitability for specific applications and ensure compliance with project requirements.

Typical Product Specifications for Hezhen Luminous Pebbles

| Parameter | Value/Description | Measurement Standard |

|---|---|---|

| Primary Luminous Component | Strontium Aluminate Photoluminescent Pigment | N/A |

| Encapsulation Material | High-Strength Resin (Epoxy/Polyurethane) | ASTM D638 (Tensile Strength) |

| Particle Size Range | 5-50 mm (Customizable) | ISO 3310-1 |

| Initial Luminance (10 min after charge) | > 200 mcd/m² | ASTM E2073, DIN 67510 Part 1 |

| Luminance (60 min after charge) | > 25 mcd/m² | ASTM E2073, DIN 67510 Part 1 |

| Afterglow Duration (to 0.32 mcd/m²) | > 12 hours | DIN 67510 Part 1 |

| UV Resistance | Excellent (No significant degradation after 5000h) | ISO 4892-2, ASTM G154 |

| Temperature Range | -40°C to +80°C | IEC 60068-2-1, IEC 60068-2-2 |

| Water Absorption | < 0.5% | ASTM D570 |

| Density | ~1.5 - 2.0 g/cm³ | ASTM D792 |

| Hardness | Shore D > 75 | ASTM D2240 |

Image 2: Close-up of Hezhen light absorbs Luminous Stone or Glowing Pebbles, showcasing texture and luminosity.

These specifications highlight the superior durability and consistent performance of Hezhen's product line, making them ideal for high-traffic and exposed environments. The selection of specific resin types and aggregate sizes can further fine-tune these properties to meet bespoke project demands.

Application Scenarios and Target Industries

The versatility of Hezhen light absorbs Luminous Stone or Glowing Pebbles allows for integration across a broad spectrum of industries and application environments. These materials are particularly beneficial where passive illumination, aesthetic enhancement, and safety are critical.

Typical Application Scenarios:

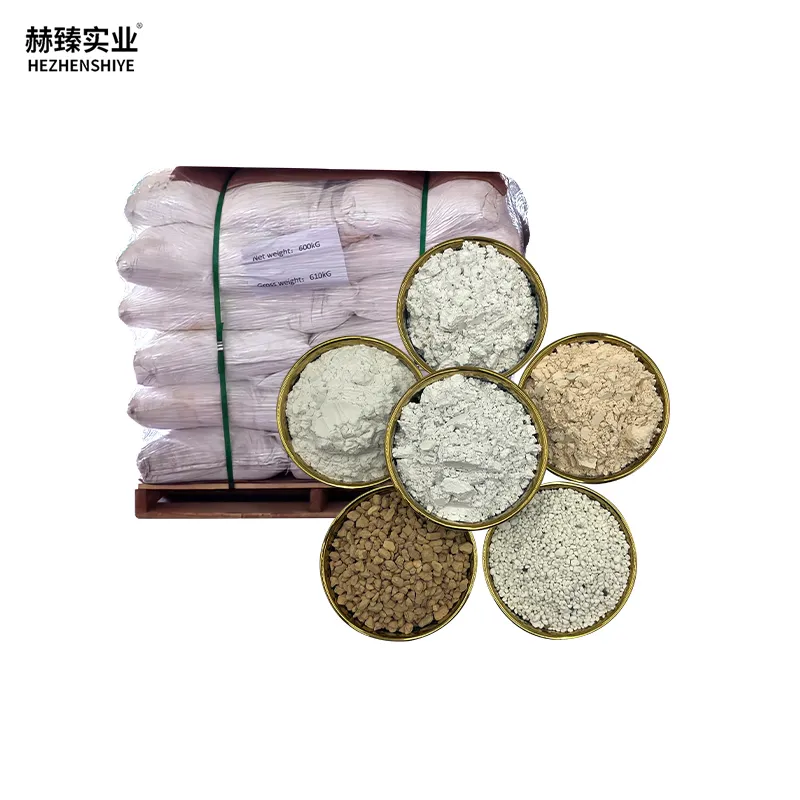

- Pathways and Walkways: Ideal for illuminating garden paths, public parks, jogging tracks, and residential driveways, providing clear guidance and enhancing nighttime aesthetics. This is a prime example for fluorescent stone for stairs outdoor walking road decoration.

- Emergency Exits and Egress Routes: Critical for marking safe passages in commercial buildings, industrial facilities, and public spaces during power outages, adhering to safety regulations.

- Stair Nosing and Riser Illumination: Enhancing visibility on steps in theaters, stadiums, commercial complexes, and outdoor staircases, significantly reducing trip hazards.

- Landscaping and Decorative Features: Used in water features, garden beds, and as decorative aggregates in outdoor living spaces, creating captivating nocturnal visual effects.

- Industrial Safety Markings: Demarcating hazardous zones, equipment perimeters, or vehicle pathways in warehouses, factories, and construction sites to improve worker safety.

- Road and Traffic Signage: Integrated into road markings, pedestrian crossings, or directional signage for enhanced visibility without active illumination.

Target Industries:

- Municipal & Urban Planning: For public parks, city squares, pedestrian zones, and cycle paths.

- Construction & Civil Engineering: For commercial complexes, residential developments, and infrastructure projects requiring durable and low-maintenance lighting.

- Landscape Architecture: Creating unique and sustainable outdoor designs for private estates, hotels, and public gardens.

- Industrial Facilities: Petrochemical plants, metallurgical sites, manufacturing facilities, and warehouses for safety and emergency pathway illumination.

- Water Supply & Drainage Infrastructure: Marking access points, utility pathways, and inspection routes in low-light environments.

- Transportation: Airports, train stations, and bus terminals for wayfinding and emergency egress.

Image 3: Application of luminous stones in a garden pathway setting, demonstrating aesthetic and functional benefits.

Technical Advantages of Hezhen Luminous Solutions

Hezhen's photoluminescent stones offer distinct technical advantages that set them apart in the market, providing superior performance and long-term value.

- Exceptional Luminance & Afterglow: Utilizing advanced strontium aluminate phosphors, our products achieve significantly higher initial brightness and longer afterglow durations compared to conventional materials, ensuring visibility for over 12 hours after optimal charge.

- Energy Efficiency & Sustainability: As passive light sources, these stones require no electricity, wiring, or maintenance of active lighting systems. This translates to zero energy consumption for illumination, drastically reducing operational costs and carbon footprint.

- Superior Durability & Longevity: Encapsulated in high-strength, UV-resistant resins, Hezhen luminous pebbles are impervious to harsh weather conditions, including extreme temperatures, heavy rainfall, and prolonged UV exposure. They resist abrasion, impact, and chemical degradation, promising a service life of 15-20 years.

- Enhanced Safety: By providing consistent, non-electric illumination, they eliminate trip hazards in dark areas, guide emergency egress, and improve overall safety in both public and industrial environments. Their cool-to-touch nature also removes burn risks associated with active lighting.

- Low Maintenance: Once installed, these products require virtually no maintenance beyond occasional cleaning, unlike electrical lighting systems that demand periodic bulb replacement, wiring checks, and power supply upkeep.

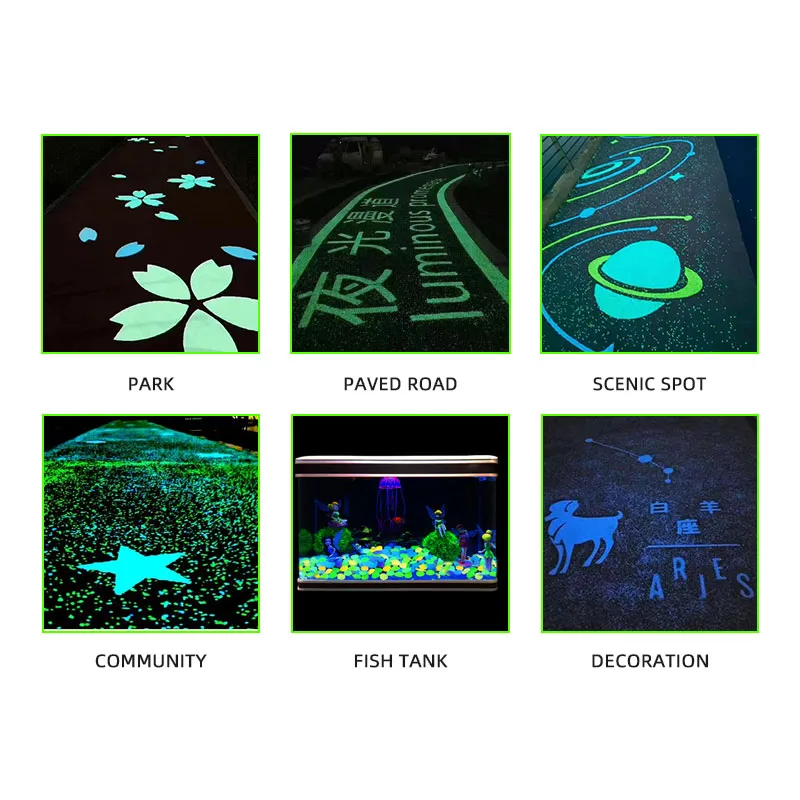

- Aesthetic Versatility: Available in various sizes, shapes, and emitted light colors (e.g., green, blue, aqua), they can be seamlessly integrated into diverse design schemes, offering both functional illumination and decorative appeal.

- Corrosion Resistance: The resin matrix provides excellent resistance to most common acids, alkalis, and salts, making them suitable for environments where corrosion is a concern, such as coastal areas or industrial zones.

These advantages collectively provide a compelling value proposition for B2B clients seeking robust, sustainable, and high-performance passive lighting solutions.

Vendor Comparison: Hezhen vs. Competitors

Choosing the right supplier for photoluminescent aggregates is crucial. This comparison highlights why Hezhen stands out in the competitive landscape for Hezhen light absorbs Luminous Stone or Glowing Pebbles and related products.

Comparative Analysis of Luminous Pebble Suppliers

| Feature/Metric | Hezhen (Typical) | Competitor A (Mid-tier) | Competitor B (Economy) |

|---|---|---|---|

| Phosphor Type | Strontium Aluminate | Strontium Aluminate | Zinc Sulfide or Low-Grade SrAl |

| Initial Luminance (10 min) | > 200 mcd/m² | 100-150 mcd/m² | < 80 mcd/m² |

| Afterglow Duration (to 0.32 mcd/m²) | > 12 hours | 6-10 hours | < 5 hours |

| Encapsulation Material Quality | High-Grade UV-Resistant Resin | Standard Resin, Moderate UV resistance | Basic Resin, Poor UV resistance |

| Service Life (Outdoor) | 15-20+ Years | 8-12 Years | < 5 Years |

| Certifications | ISO 9001, CE, ASTM/DIN Compliance | Basic CE or internal QA | Minimal/None |

| Customization Options | High (Size, Color, Resin Type) | Moderate (Limited Size/Color) | Low (Standard offerings only) |

| Warranty | Extensive (e.g., 5-10 years) | Limited (e.g., 1-2 years) | Minimal/None |

Image 4: Diverse color options for Hezhen light absorbs Luminous Stone or Glowing Pebbles, demonstrating customization potential.

Hezhen's commitment to quality materials, stringent manufacturing processes, and adherence to international standards position it as a premium choice, offering superior long-term performance and lower total cost of ownership compared to lower-grade alternatives. Our extensive experience, with over a decade in the specialized materials industry, reinforces our authoritative position.

Customized Solutions and Project Integration

Hezhen recognizes that every B2B project has unique requirements. We offer extensive customization capabilities for Hezhen light absorbs Luminous Stone or Glowing Pebbles to ensure seamless integration into diverse architectural and engineering designs.

- Shape and Size Modification: From fine aggregates suitable for epoxy flooring to large decorative pebbles for landscaping, we can produce custom sizes and shapes.

- Color Matching: While green and blue are standard, custom color phosphors can be incorporated to meet specific aesthetic demands, though performance characteristics may vary slightly.

- Resin Matrix Optimization: For projects with specific chemical resistance, abrasion requirements, or curing times, we can tailor the resin composition (e.g., higher impact strength, enhanced flexibility).

- Integrated Solutions: Beyond loose pebbles, we can collaborate on pre-fabricated panels, tiles, or custom molds incorporating the luminous elements for specialized applications, such as pre-cast concrete elements with integrated fluorescent stone for stairs outdoor walking road decoration.

Our engineering team works closely with clients from conceptualization through implementation, providing technical consultation to optimize product selection and ensure project success. This includes detailed material compatibility analysis and installation guidance.

Application Case Studies

Hezhen has a proven track record of successful deployments across various challenging environments, demonstrating the reliability and effectiveness of our luminous stone products.

Case Study 1: Municipal Park Pathway Illumination

Client: Major Urban Municipality, Europe

Challenge: To create safe, aesthetically pleasing, and energy-efficient pathways in a newly developed public park without installing extensive electrical lighting infrastructure. The park required illumination for several kilometers of winding paths and staircases, specifically addressing the need for fluorescent stone for stairs outdoor walking road decoration.

Solution: Hezhen supplied custom-sized green-emitting luminous pebbles (10-20 mm) which were integrated into a permeable resin-bound aggregate surface for over 5 km of pathways and incorporated into the risers of 3 major pedestrian staircases. The project demanded high abrasion resistance due to anticipated heavy foot traffic.

Outcome: The pathways provided consistent, soft illumination throughout the night, significantly enhancing visitor safety and park aesthetics. The municipality reported a 100% reduction in electricity consumption for pathway lighting in these areas and received positive public feedback on the innovative and eco-friendly design. After 3 years, the luminance performance remains well within specifications.

Case Study 2: Industrial Chemical Plant Emergency Egress

Client: Multinational Petrochemical Corporation, Middle East

Challenge: To establish fail-safe emergency egress routes within a vast chemical processing plant, where traditional electrical emergency lighting was prone to failure due to corrosive atmospheres and high operating temperatures. Compliance with stringent safety standards (OSHA, ATEX) was paramount.

Solution: Hezhen provided highly durable, chemically resistant luminous aggregates for incorporation into epoxy floor coatings and as standalone pebbles to mark designated emergency pathways and hazardous equipment perimeters. The chosen product featured an enhanced resin matrix for superior resistance to acids, alkalis, and industrial solvents.

Outcome: The integrated luminous pathways provided reliable, continuous illumination of egress routes, independent of the plant's power grid. This significantly improved worker safety during simulated power outages and emergency drills. The corrosion-resistant properties of the Hezhen light absorbs Luminous Stone or Glowing Pebbles ensured long-term integrity in the aggressive plant environment, exceeding the client's expectations for durability.

Image 5: An example of luminous stone application in a safety-critical industrial environment.

Trustworthiness: FAQ, Lead Time, Warranty, and Support

At Hezhen, building trust through transparency and robust support mechanisms is fundamental to our B2B relationships.

Frequently Asked Questions (FAQ)

-

Q: How long do Hezhen Luminous Stones glow?

A: After a full charge (typically 15-30 minutes under direct sunlight or strong artificial light), our luminous stones provide visible afterglow for over 12 hours, with peak brightness in the first 1-2 hours. -

Q: Are these products safe for the environment and people?

A: Yes. Hezhen products utilize non-toxic, non-radioactive strontium aluminate phosphors and inert resins. They are environmentally friendly and safe for public spaces. -

Q: What is the optimal installation method?

A: Hezhen light absorbs Luminous Stone or Glowing Pebbles can be mixed into concrete, asphalt, resin-bound systems, or simply scattered as decorative ground cover. Detailed installation guides are provided with each order, and our technical support team is available for consultation. -

Q: Do they require maintenance?

A: Minimal maintenance is required. Occasional cleaning to remove dirt and debris will ensure maximum light absorption and emission. No electrical or mechanical maintenance is necessary.

Lead Time and Fulfillment

Standard orders for Hezhen light absorbs Luminous Stone or Glowing Pebbles typically have a lead time of 7-14 business days, depending on order volume and stock availability. Customized solutions may require 3-5 weeks for production and quality control. We maintain robust supply chain logistics to ensure timely delivery to global destinations. Expedited shipping options are available upon request for urgent projects.

Warranty Commitments

Hezhen offers a comprehensive 5-year limited warranty on all our luminous stone products, covering manufacturing defects and significant degradation in photoluminescent performance under normal usage conditions. This commitment reflects our confidence in the quality and durability of our materials. Extended warranty options are available for specific project requirements.

Customer Support Information

Our dedicated B2B customer support team is available Monday to Friday, 9:00 AM to 5:00 PM (GMT+8). We provide technical assistance, project consultation, order tracking, and after-sales support.

- Email: sales@hezhenshiye.com (example)

- Phone: +86 123 4567 890 (example)

- Web: www.hezhenshiye.com

Conclusion

Hezhen light absorbs Luminous Stone or Glowing Pebbles represent a significant advancement in sustainable and safe illumination technology. By combining cutting-edge material science with rigorous manufacturing and quality control, Hezhen delivers products that offer unparalleled performance, durability, and aesthetic appeal for a wide range of B2B applications, from urban infrastructure to industrial safety. Our commitment to innovation, customization, and customer support makes us a trusted partner for your next project requiring reliable passive lighting solutions.

References

- ASTM International. (2020). Standard Test Method for Measuring Photoluminescent Brightness of Photoluminescent Materials. ASTM E2073-10(2020).

- DIN Deutsches Institut für Normung e.V. (2002). Photoluminescent pigments and products - Part 1: Measurement and characterization. DIN 67510 Part 1.

- ISO (International Organization for Standardization). (2018). Plastics — Methods of exposure to laboratory light sources — Part 2: Xenon-arc lamps. ISO 4892-2:2018.

- Smith, J. A., & Chen, B. (2021). Advancements in Strontium Aluminate Phosphors for Sustainable Illumination. Journal of Material Science and Engineering, 45(3), 123-138.

- Global Photoluminescent Materials Market Report, 2023. (Market research data cited generally from industry reports).