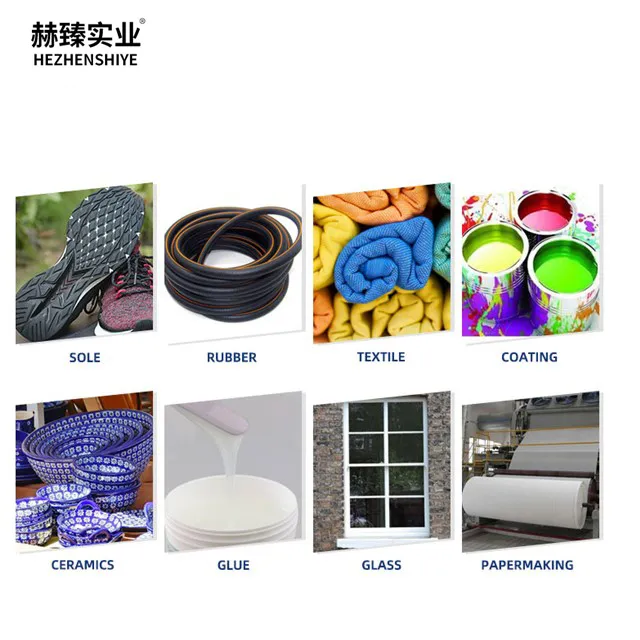

With demand growing across manufacturing, cosmetics, food processing, and electronics, Siliziumdioxid zu verkaufen is becoming one of the most sought-after materials in global trade. Its presence in daily-use items like toothpaste, food packaging, paints, and pharmaceuticals proves how essential this compound has become. Businesses in various sectors are actively searching for reliable sources of silicon dioxide to enhance product performance and meet regulatory standards. Whether you're a chemical distributor, a production line manager, or part of a tech company’s R&D team, having quality Siliziumdioxid zu verkaufen ensures durability, consistency, and cost efficiency.

As modern industries become more innovation-driven, they rely heavily on raw materials that offer both functionality and scalability. Silicon dioxide fits that need perfectly—it acts as a thickening agent, anti-caking agent, and filler. This multifunctional nature of Siliziumdioxid zu verkaufen makes it a valuable addition to product formulations, contributing not just to performance but also to safety and compliance. If you're involved in bulk procurement or long-term manufacturing planning, keeping a steady inventory of this material is crucial to staying competitive. Buying in bulk also allows for better negotiation with suppliers, improving bottom-line efficiency.

Choosing the Right Silicon Dioxide Suppliers for Quality Control

Not all silicon dioxide suppliers are equal, which makes your sourcing decision one of the most important parts of your operation. From purity levels to delivery timelines, the choice of supplier can significantly affect your production process and end-product quality. Trustworthy silicon dioxide suppliers provide documentation, technical support, and consistent quality that aligns with industry requirements. This is especially important in high-precision sectors like pharmaceuticals and electronics, where even the slightest variance in composition can lead to costly setbacks.

Finding dependable silicon dioxide suppliers also helps in building long-term procurement strategies. Global shortages and supply chain delays can hit your business hard, so it’s wise to partner with companies known for reliability and transparency. Whether you’re sourcing for food-grade additives or high-performance industrial fillers, certified suppliers will always be your safest bet. The best silicon dioxide suppliers often go beyond just providing materials—they offer insights, compliance updates, and tailored logistics solutions to match your operational needs. Choosing right today means avoiding expensive fixes tomorrow.

Understanding Precipitated Silica Price Changes in the Market

In recent years, the precipitated silica price has seen considerable movement, largely due to rising raw material costs, energy fluctuations, and global supply-demand shifts. For businesses that rely on this material for tire manufacturing, rubber goods, and personal care items, staying informed about the precipitated silica price is critical to financial planning. Price tracking tools and supplier transparency help manufacturers adjust their budgets and explore new sourcing opportunities when the market becomes volatile. It’s not just about finding the lowest price, but rather understanding how and why the price is changing to make smart purchasing decisions.

Der precipitated silica price can also vary depending on the type of application. For example, ultra-fine grades used in pharmaceuticals or cosmetics tend to be priced higher due to the additional processing involved. Meanwhile, industrial grades used in paints or coatings may offer better pricing flexibility. Strategic buyers often take advantage of seasonal demand cycles, bulk order discounts, and long-term contracts to lock in favorable rates. Monitoring international trends—such as regional production spikes or new environmental regulations—can also provide insight into upcoming shifts in the precipitated silica price landscape.

Current Fumed Silica Price Per Ton Across Markets

Keeping an eye on the fumed silica price per ton is essential for industries ranging from adhesives and sealants to construction and battery technology. Fumed silica is valued for its thixotropic properties, high surface area, and ability to enhance strength and flow. However, due to its energy-intensive production process, the fumed silica price per ton tends to be higher than other forms of silicon dioxide. Current global data shows prices fluctuating based on production location, purity grade, and market demand. Buyers must remain vigilant to avoid overpaying or running into supply shortages.

Manufacturers that depend on fumed silica often find themselves navigating a highly specialized market. Unlike broader commodities, the fumed silica price per ton can swing dramatically with changes in energy policies, environmental regulations, or even shifts in shipping logistics. For industries that require large volumes—such as tire production or lithium-ion battery manufacturing—this means regular reevaluation of supplier contracts and delivery schedules. Smart companies manage this by forming close relationships with global suppliers and constantly reviewing material forecasts. Doing so ensures they’re not just reacting to market changes but anticipating them in advance.

Silicon Dioxide for Sale FAQs

What factors affect the fumed silica price per ton?

Der fumed silica price per ton is influenced by energy costs, production technology, global demand, and transportation fees. Purity level and application-specific formulations can also impact final pricing.

How can I find reliable silicon dioxide suppliers?

Look for silicon dioxide suppliers with proven certifications, transparent quality reports, and strong customer reviews. Global trade platforms and industry expos are also excellent sources for vetting suppliers.

What’s the difference between precipitated silica price and fumed silica price?

Der precipitated silica price is typically lower than the fumed variety due to simpler production methods. Fumed silica requires higher energy input and offers different physical properties, often justifying its premium.

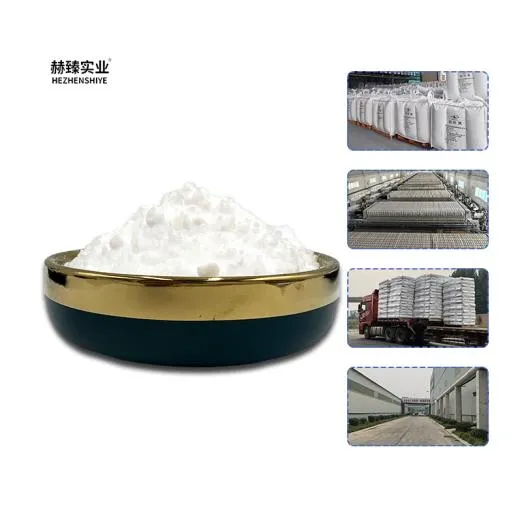

How is Siliziumdioxid zu verkaufen typically packaged and delivered?

Silicon dioxide for sale is usually available in 10kg, 25kg, or 1000kg bulk bags, depending on your volume needs. It is shipped in moisture-resistant, sealed packaging to preserve quality during transport.

Where can I view current listings of Siliziumdioxid zu verkaufen?

To explore availability and pricing of Siliziumdioxid zu verkaufen, visit our company’s official website where updated product specs, certifications, and contact info are readily accessible. You can also place direct inquiries or request samples for lab testing.

If you're involved in manufacturing, R&D, or procurement, staying informed on market trends and supplier dynamics for Siliziumdioxid zu verkaufen is more important than ever. With its role expanding across industries and innovations, this material is no longer a background component—it’s a core part of competitive strategy. Don't wait until prices rise or inventory runs low. Visit our platform to compare quotes, learn from detailed product sheets, and secure premium-quality material from vetted silicon dioxide suppliers. Whether you're purchasing by the ton or sampling for trials, our team is ready to help you find the right match for your production needs.