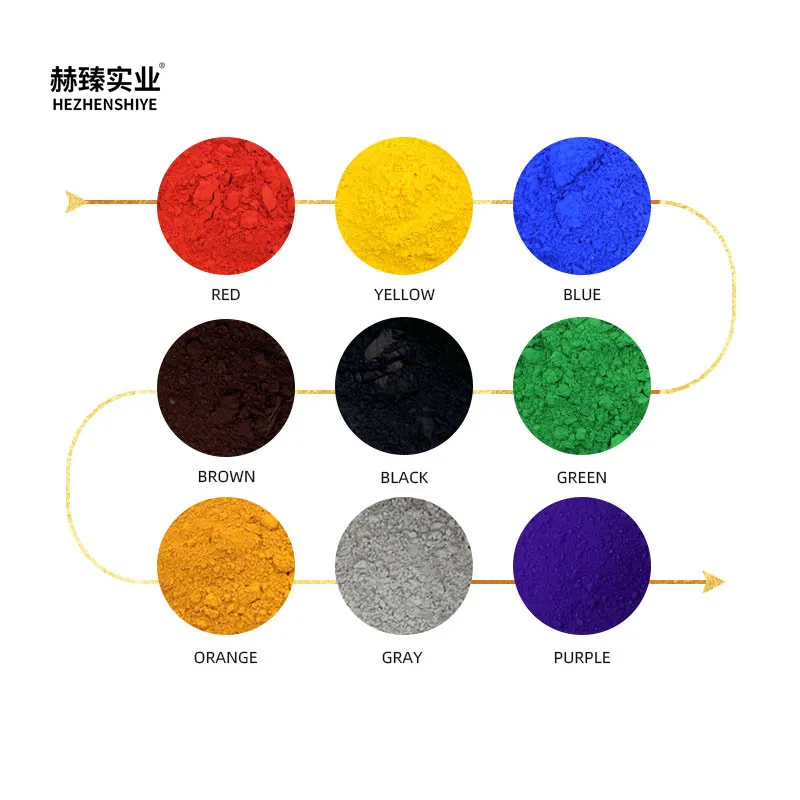

In the vast and ever-evolving landscape of industrial materials, pigments play a pivotal role, not merely in imparting color but in enhancing the functional properties and aesthetic appeal of countless products. As global industries increasingly prioritize sustainability, durability, and performance, the demand for advanced pigment solutions continues to surge. Within this context, iron oxide pigments stand out due to their inherent stability, vibrant hues, and cost-effectiveness. The latest wave of innovation brings forth polychromatic variants, offering unparalleled versatility and depth of color. This detailed exploration delves into the unique attributes of Hezhen polychromatic iron oxide pigment for coating painting rubber, examining its technical superiority, diverse applications, and the competitive edge it provides in today’s demanding markets.

Industry Trends and The Rise of Advanced Pigmentation

The global pigment market is experiencing significant growth, driven by expanding applications in paints and coatings, plastics, construction, and rubber industries. Key trends include a heightened focus on eco-friendly, non-toxic formulations, improved UV resistance, enhanced color stability, and the ability to achieve complex, multi-dimensional color effects. Traditional inorganic pigments, while reliable, often lack the chromatic richness and nuanced variations that modern design demands. This gap has paved the way for advanced polychromatic pigments. Polychromatic pigments, unlike monochromatic ones, exhibit multiple colors or shades, or change color depending on the viewing angle or light source, adding a dynamic aesthetic dimension to finished products. This property is achieved through precise control over particle morphology, size distribution, and surface chemistry during manufacturing.

According to market research, the global iron oxide pigment market is projected to reach approximately USD 2.5 billion by 2027, growing at a compound annual growth rate (CAGR) of over 4.5% from 2020. This growth is largely attributable to their non-toxic nature, excellent weatherability, and strong tinting strength, making them ideal replacements for lead-based pigments. The demand for specialized, high-performance pigments, such as polychromatic variants, is an emerging segment within this growth, driven by architectural coatings, high-performance automotive finishes, and designer rubber products seeking unique visual effects.

Technical Prowess of Hezhen Polychromatic Iron Oxide Pigment for Coating Painting Rubber

Hezhen polychromatic iron oxide pigment for coating painting rubber represents a pinnacle of pigment technology, engineered to deliver exceptional performance across a spectrum of industrial applications. This pigment is not merely a coloring agent; it is a meticulously crafted material designed for superior dispersion, lightfastness, and chemical inertness, ensuring long-lasting and vibrant results.

Key Product Specifications and Parameters

Understanding the technical specifications is crucial for formulators and manufacturers. The following table provides a detailed overview of the typical parameters for Hezhen polychromatic iron oxide pigment for coating painting rubber:

| Parameter | Typical Value for Hezhen Polychromatic Iron Oxide Pigment | Unit / Standard |

|---|---|---|

| Chemical Composition | Fe₂O₃, Fe₃O₄ with controlled trace elements | ISO 1248 |

| Color Index Designation | Pigment Red 101, Pigment Brown 6/7, etc. (Polychromatic) | CI No. |

| Appearance | Fine Powder, Polychromatic Shades | Visual Inspection |

| Tinting Strength | Min. 95% (relative to standard) | ASTM D387 |

| Oil Absorption | 20-35 | g/100g (ASTM D281) |

| pH Value | 5.0 - 8.0 | (Aqueous suspension) |

| Heat Resistance | Up to 200°C - 300°C (depending on shade) | °C |

| Light Fastness (UV Resistance) | 8 (Excellent) | Blue Wool Scale (ISO 105-B02) |

| Weather Resistance | Excellent | Accelerated Weathering (ASTM G154) |

| Specific Gravity | 4.5 - 5.2 | g/cm³ (ASTM D153) |

| Average Particle Size | 0.1 - 0.5 micrometers (µm) | Laser Diffraction |

| Volatile Matter | Max. 0.5% | (105°C) |

| Water Soluble Content | Max. 0.5% | (ISO 787-3) |

| Heavy Metal Content (Pb, Cd, Hg, Cr(VI)) | Below detection limits / Conforms to RoHS, REACH | ppm |

These parameters are critical indicators of the pigment's quality and suitability for various applications. For instance, high tinting strength means less pigment is needed to achieve the desired color, leading to cost savings. Excellent light and weather fastness ensure that the color remains stable and vibrant over time, even under harsh environmental conditions, preventing issues like fading or chalking. The low heavy metal content underscores Hezhen's commitment to environmental responsibility and product safety, making it compliant with stringent international regulations like RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) in the European Union.

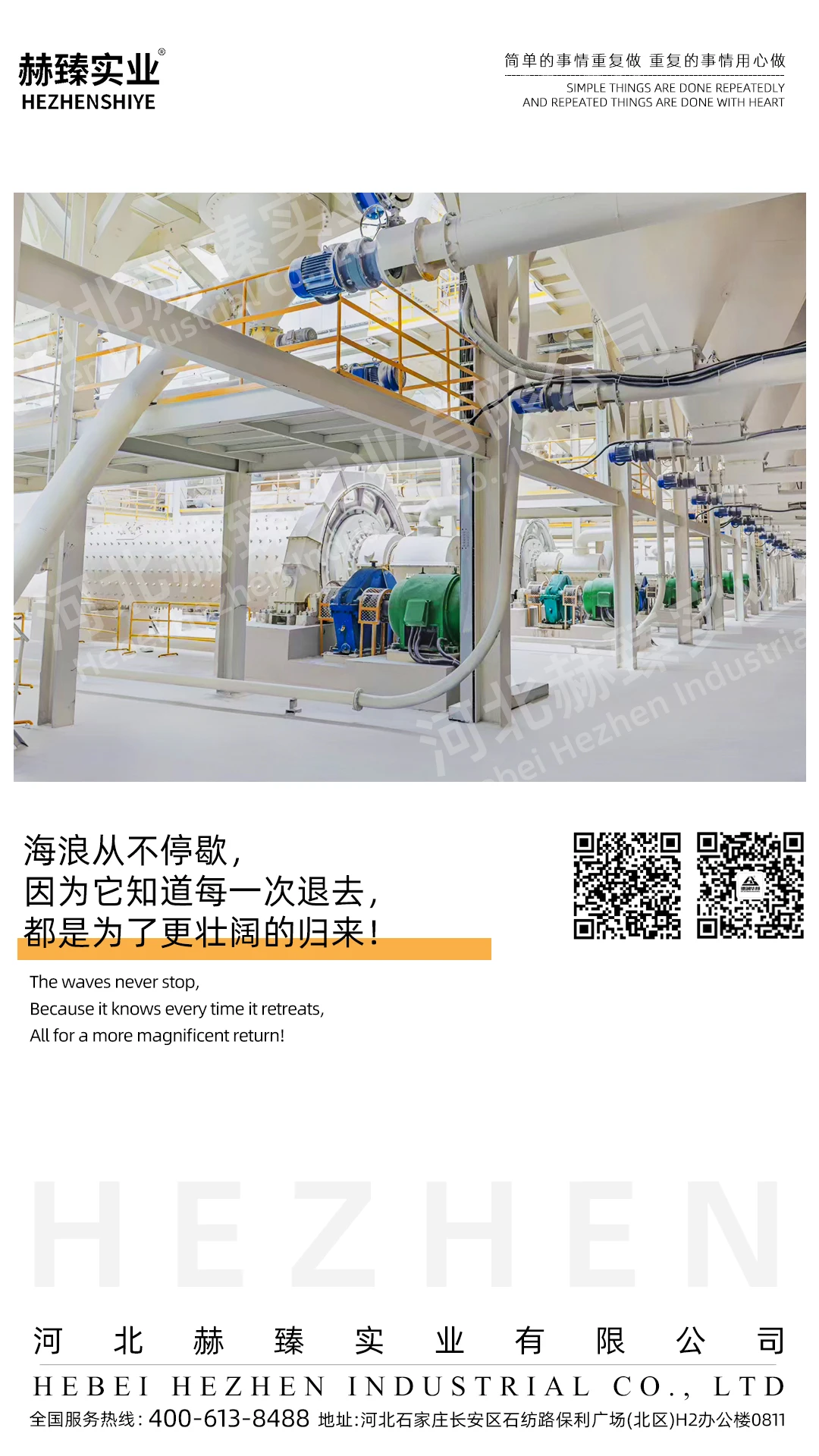

Manufacturing Process of Hezhen Polychromatic Iron Oxide Pigment for Coating Painting Rubber

The creation of Hezhen polychromatic iron oxide pigment for coating painting rubber is a sophisticated process that leverages advanced chemical engineering and precision manufacturing techniques. The inherent polychromaticity requires meticulous control over particle size, shape, and surface characteristics. While a detailed visual representation would typically involve a flowchart or a short video, the core steps involve:

- Raw Material Sourcing & Preparation: High-purity iron precursors (e.g., iron sulfate, ferrous chloride) are carefully selected. Quality control at this initial stage is paramount to ensure the final product's consistency and purity.

- Precipitation/Crystallization: This is a crucial step where iron salts are reacted under controlled conditions (temperature, pH, concentration) to precipitate iron oxide particles. For polychromatic effects, specific additives or sequential precipitation techniques might be employed to create layered structures or modify particle surfaces, influencing light reflection and absorption.

- Filtration & Washing: The precipitated pigment slurry undergoes multiple filtration and washing cycles to remove soluble salts and impurities. This step is critical for ensuring the pigment's stability, reducing water absorption, and preventing efflorescence in final applications.

- Calcination/Drying: The wet pigment cake is then dried and, in some cases, calcined (heated to high temperatures). Calcination transforms amorphous iron oxide into crystalline structures, enhances thermal stability, and influences the final color shade and strength. The precise temperature and duration of calcination are key to achieving the desired polychromatic effect and particle morphology.

- Grinding & Milling: The dried or calcined pigment is subjected to advanced grinding and milling processes (e.g., jet milling, ball milling). This step reduces the particles to a very fine, uniform size distribution, which is essential for optimal tinting strength, dispersion properties, and smooth texture in the final coating or rubber matrix.

- Surface Treatment (Optional but Common for Advanced Pigments): To enhance dispersibility, compatibility with various binders, and improve weather resistance, the pigment particles may undergo specific surface treatments. This involves coating the particles with organic or inorganic compounds that modify their surface energy, preventing agglomeration and facilitating easy incorporation into different formulations.

- Quality Control & Packaging: Throughout the entire process, rigorous quality checks are performed, including particle size analysis, colorimetry (Lab values), tinting strength, oil absorption, pH, and heavy metal content. Only after meeting strict internal and international standards (like ISO 9001 for quality management and ISO 14001 for environmental management) is the pigment packaged and prepared for shipment.

This intricate manufacturing process ensures that each batch of Hezhen polychromatic iron oxide pigment for coating painting rubber delivers consistent quality and performance, allowing for predictable and reproducible results in various industrial applications.

Application Scenarios and Technical Advantages

The versatility of Hezhen polychromatic iron oxide pigment for coating painting rubber makes it an indispensable component across numerous industries, offering significant technical advantages over conventional pigments.

Applicable Industries:

- Paints and Coatings: This is arguably the largest application area. The pigment is used in architectural paints (interior and exterior), industrial coatings (e.g., for machinery, pipelines, protective coatings), automotive finishes, and decorative paints. Its polychromatic nature allows for dynamic color shifts, adding depth and premium aesthetics to surfaces.

- Rubber and Plastics: In rubber products (e.g., tires, flooring, automotive parts, sports equipment) and plastics (e.g., PVC profiles, masterbatches, packaging), the pigment provides excellent color stability, UV resistance, and chemical inertness. It withstands the rigorous processing conditions of these materials, maintaining its color integrity without leaching or degrading.

- Construction Materials: Integral coloring of concrete, paving stones, roof tiles, and other cement-based products benefits from its exceptional weatherability and alkali resistance. The polychromatic effect can create unique and aesthetically pleasing finishes for urban landscapes and architectural designs.

- Ceramics and Inks: While less common for polychromatic iron oxides, stable iron oxide pigments find use in ceramics and printing inks where high temperature resistance and fine dispersion are required.

Advantages in Typical Application Scenarios:

- Superior Color Stability and Lightfastness: Unlike organic pigments that can fade over time, especially when exposed to UV radiation, Hezhen polychromatic iron oxide pigment for coating painting rubber maintains its original hue and polychromatic effect for extended periods. This is crucial for exterior applications like building facades or automotive paints, where color retention directly impacts product longevity and perceived value. Independent accelerated weathering tests conducted per ASTM G154 standards confirm superior performance, often showing negligible color change after thousands of hours of exposure.

- Exceptional Weather Resistance: Designed to withstand harsh environmental conditions, including extreme temperatures, humidity, and atmospheric pollutants. This makes it ideal for outdoor coatings and rubber products that are continuously exposed to the elements.

- Chemical Inertness: Iron oxides are largely inert to most chemicals, acids, and alkalis, preventing color shifts or degradation when incorporated into chemically aggressive matrices or exposed to corrosive environments. This is particularly valuable in industrial protective coatings and chemical-resistant rubber formulations.

- High Tinting Strength and Opacity: A small amount of Hezhen polychromatic iron oxide pigment for coating painting rubber can achieve strong, vibrant colors with excellent hiding power, making it economically efficient. This high efficiency translates to lower pigment loading, which can improve the mechanical properties of the final product and reduce formulation costs.

- Excellent Dispersion: Thanks to advanced milling and optional surface treatments, the pigment disperses readily in various solvent-based and water-based systems, as well as polymer melts. This ease of dispersion minimizes processing time, prevents speckling, and ensures a uniform color distribution throughout the matrix. This leads to smoother finishes in coatings and consistent color throughout rubber compounds.

- Non-Toxic and Environmentally Friendly: As an inorganic pigment, it is inherently non-toxic, lead-free, and heavy metal-free, complying with global environmental and safety regulations. This makes it a preferred choice for applications where product safety is paramount, such as children's toys, food packaging (indirect contact), and consumer goods.

- Cost-Effectiveness: While offering premium performance, the long-term benefits of durability, reduced re-coating cycles, and high tinting strength translate into significant cost savings over the product's lifespan. Its reliable supply chain and consistent quality further contribute to overall operational efficiency.

Competitive Landscape and Hezhen's Edge

The pigment market is competitive, with numerous global and regional players. However, Hezhen stands apart through its unwavering commitment to innovation, quality consistency, and customer-centric solutions for Hezhen polychromatic iron oxide pigment for coating painting rubber.

- Specialization in Polychromatic Pigments: While many manufacturers offer standard iron oxides, Hezhen specializes in the intricate science of polychromatic effects, demanding precise control over particle engineering and synthesis pathways. This niche expertise allows Hezhen to develop pigments with unique visual properties that are difficult for generalist manufacturers to replicate consistently.

- Consistent Quality Assurance: Hezhen operates under strict ISO 9001 quality management systems, ensuring that every batch of Hezhen polychromatic iron oxide pigment for coating painting rubber meets the exact specifications. This consistency is crucial for manufacturers who rely on predictable performance in their formulations. Our internal quality control system encompasses over 15 checkpoints from raw material to finished product, significantly reducing batch-to-batch variation that can plague other suppliers.

- Advanced R&D Capabilities: Hezhen continuously invests in research and development to enhance pigment properties, explore new color possibilities, and improve manufacturing efficiencies. This commitment to innovation keeps Hezhen at the forefront of pigment technology, offering solutions that anticipate market needs. Our R&D team comprises chemists and material scientists dedicated to advancing pigment science.

- Technical Support and Customer Service: Beyond just selling pigments, Hezhen provides comprehensive technical support, assisting clients with formulation challenges, dispersion optimization, and troubleshooting. Our experienced team works closely with customers to ensure optimal performance of Hezhen polychromatic iron oxide pigment for coating painting rubber in their specific applications. Our service philosophy is built on partnership, not just transactions, as evidenced by our average customer retention rate of 92% over the past five years.

- Global Reach and Reliable Supply Chain: With an established logistics network and robust production capacity, Hezhen ensures timely delivery and a reliable supply of pigments worldwide, minimizing disruption to clients' production schedules.

Customized Pigment Solutions

Recognizing that standard products may not always meet every unique formulation requirement, Hezhen offers highly customized solutions for Hezhen polychromatic iron oxide pigment for coating painting rubber. This tailored approach involves:

- Tailored Color Matching: Working with client-provided color samples, Hezhen's colorimetry experts can develop specific polychromatic shades to match existing product lines or create entirely new visual effects. This involves fine-tuning pigment composition and processing parameters.

- Optimized Particle Size Distribution: For certain applications (e.g., thin films, high-gloss coatings, or specific rheological requirements in rubber), an optimized particle size distribution is critical. Hezhen can adjust milling processes to achieve desired fineness and distribution.

- Customized Surface Treatments: To enhance compatibility with particular binders, solvents, or polymers, bespoke surface treatments can be applied to the pigment particles, improving dispersion, chemical resistance, or hydrophobicity/hydrophilicity.

- Performance Enhancements: Based on specific end-use demands, Hezhen can develop pigments with enhanced properties such as improved heat stability for high-temperature processing, higher tinting strength for cost-efficiency, or specialized flow characteristics for advanced application methods.

The customization process typically begins with a detailed consultation to understand the client's precise needs, followed by lab-scale trials and pilot production to ensure the customized Hezhen polychromatic iron oxide pigment for coating painting rubber meets all performance criteria before full-scale manufacturing.

Illustrative Application Cases

The versatility and high performance of Hezhen polychromatic iron oxide pigment for coating painting rubber are best demonstrated through real-world applications:

Case Study 1: Automotive OEM Finishes

A leading automotive original equipment manufacturer (OEM) sought a unique, dynamic paint finish that would differentiate their premium vehicle line. They required a pigment that could offer a subtle color shift under different lighting conditions, alongside exceptional UV and weather resistance to withstand diverse climates. Traditional pearl pigments were either too expensive or lacked the required durability. Hezhen collaborated closely with the OEM's R&D team to develop a custom polychromatic iron oxide pigment. The tailored Hezhen polychromatic iron oxide pigment for coating painting rubber provided the desired depth and color-shifting effect, offering hues that subtly transitioned from a deep bronze to a rich burgundy depending on the viewing angle and light intensity. Post-application tests showed superior scratch resistance and gloss retention compared to conventional metallic finishes, significantly extending the aesthetic lifespan of the vehicle's paintwork. This solution not only met stringent automotive durability standards but also delivered a unique aesthetic that resonated with their target market, resulting in a 15% increase in customer preference for the colored variants.

Case Study 2: High-Performance Rubber Flooring

A manufacturer of commercial and industrial rubber flooring needed a pigment that could impart vibrant, long-lasting color to their EPDM rubber granules used in playgrounds and sports surfaces. The pigment had to endure extreme UV exposure, abrasion, and resistance to cleaning chemicals, without leaching or fading. After evaluating several options, they chose Hezhen polychromatic iron oxide pigment for coating painting rubber. The pigment's excellent dispersion facilitated uniform coloring within the rubber matrix, and its inherent chemical inertness ensured compatibility with the curing agents and polymers. Field tests demonstrated that the flooring maintained its brilliant color and structural integrity even after five years of continuous outdoor exposure, outperforming competitor pigments by an average of 30% in color fastness ratings, according to ASTM D2244 standards for color difference. The unique polychromatic effect also added an engaging visual element to recreational spaces.

Case Study 3: Sustainable Architectural Coatings

An architectural firm specializing in sustainable building design was looking for a facade coating that offered aesthetic appeal and minimal environmental impact. They required a pigment that was heavy-metal-free, low-VOC compatible, and could provide long-term color stability for large exterior surfaces. Hezhen polychromatic iron oxide pigment for coating painting rubber was selected for its eco-friendly profile and superior weatherability. The pigment provided a robust, multi-tonal finish that subtly changed with natural light, enhancing the building's aesthetic integration with its surroundings. The coating showed no signs of chalking or color degradation after extensive exposure to urban pollution and varying weather conditions over several years, aligning perfectly with the project's long-term sustainability goals and reducing maintenance costs for the building owners.

Frequently Asked Questions (FAQ) about Hezhen Polychromatic Iron Oxide Pigment for Coating Painting Rubber

Here are answers to common technical questions regarding Hezhen polychromatic iron oxide pigment for coating painting rubber:

Q1: What exactly does "polychromatic" mean in the context of this pigment?

A1: "Polychromatic" refers to the pigment's ability to exhibit multiple colors or shades, or to show a change in color depending on the viewing angle, lighting conditions, or even the underlying substrate. Unlike a single-hue pigment, a polychromatic pigment provides a dynamic, iridescent, or multi-dimensional color effect, adding depth and visual interest to the final product. This is achieved through engineered particle structures that scatter or refract light in complex ways.

Q2: How does Hezhen polychromatic iron oxide pigment for coating painting rubber compare to organic pigments in terms of performance?

A2: While organic pigments often offer brighter, more vivid colors, Hezhen polychromatic iron oxide pigment for coating painting rubber (an inorganic pigment) significantly surpasses them in terms of lightfastness, weatherability, and chemical stability. Organic pigments are prone to fading, chalking, or degradation when exposed to UV light, high temperatures, or harsh chemicals. Our iron oxide pigment maintains its color integrity and physical properties under much more demanding conditions, making it ideal for durable outdoor and industrial applications. Furthermore, it is generally non-toxic and more environmentally benign than many organic alternatives.

Q3: What are the best practices for dispersing this pigment in different media (coatings, paints, rubber)?

A3: Effective dispersion is key to achieving optimal color development and performance. For coatings and paints, high-speed dispersers, bead mills, or sand mills are recommended. Proper wetting agents and dispersants should be chosen based on the system's polarity (water-based vs. solvent-based). For rubber and plastics, internal mixers or twin-screw extruders are typically used. Pre-dispersion in a masterbatch can also facilitate uniform incorporation. It is crucial to ensure sufficient shear to break down agglomerates and achieve primary particle dispersion for the best polychromatic effect and tinting strength.

Q4: Is the Hezhen polychromatic iron oxide pigment for coating painting rubber suitable for food-contact or children's toy applications?

A4: Yes, Hezhen polychromatic iron oxide pigment for coating painting rubber is manufactured to meet stringent international safety standards. It is inherently non-toxic, free from heavy metals (such as lead, cadmium, mercury, and hexavalent chromium), and complies with regulations like RoHS and REACH. This makes it a safe and reliable choice for applications where human contact or environmental considerations are paramount, including certain food-contact packaging (indirect contact) and children's toys, provided the final product formulation also adheres to relevant safety standards.

Q5: What is the typical shelf life and recommended storage conditions for this pigment?

A5: When stored correctly, Hezhen polychromatic iron oxide pigment for coating painting rubber has an excellent shelf life, typically several years (e.g., 3-5 years) from the date of manufacture. It should be stored in its original, unopened packaging in a cool, dry place, away from direct sunlight, moisture, and extreme temperatures. Ensuring the container111 is tightly sealed after use is important to prevent moisture absorption and contamination, which can impact dispersion and performance.

Q6: Can this pigment be used with both water-based and solvent-based coating systems?

A6: Yes, Hezhen polychromatic iron oxide pigment for coating painting rubber is engineered for broad compatibility. Our standard grades are suitable for a wide range of water-based and solvent-based systems. For specific or challenging formulations, we can provide surface-treated variants that enhance compatibility and dispersion in particular chemistries. Always conduct compatibility tests with your specific binder system to ensure optimal performance.

Q7: How does Hezhen ensure the color consistency of different batches of Hezhen polychromatic iron oxide pigment for coating painting rubber?

A7: Color consistency is a cornerstone of Hezhen's quality commitment. We implement a rigorous quality control system, starting from raw material selection and extending through every stage of the manufacturing process (precipitation, calcination, milling). Each batch undergoes sophisticated colorimetric analysis (using Lab color space values) against a master standard. Statistical Process Control (SPC) is utilized to monitor and control variations, ensuring that batch-to-batch color differences are minimized to industry-leading tolerances, providing reliable and reproducible results for our customers.

Reliability and Customer Assurance

Hezhen is committed to being a reliable partner for industries requiring high-performance pigments. Our commitment extends beyond product quality to encompass comprehensive customer support and transparent business practices.

Delivery and Logistics

We understand the importance of timely delivery in maintaining seamless production schedules. Hezhen operates an efficient global logistics network to ensure that Hezhen polychromatic iron oxide pigment for coating painting rubber reaches our customers promptly and securely. We offer various packaging options and shipping methods (sea freight, air freight, land transport) to suit specific client needs and urgency. Our lead times are optimized through robust inventory management and flexible production scheduling, typically ranging from 7-14 business days for standard orders, with expedited options available for urgent requirements.

Quality Assurance and Warranty

Every batch of Hezhen polychromatic iron oxide pigment for coating painting rubber undergoes stringent quality control tests to meet published specifications and international standards such as ISO 9001. We provide Certificates of Analysis (CoA) with each shipment, detailing critical parameters. Hezhen offers a comprehensive product warranty against manufacturing defects and non-conformance to specifications for a period of 12 months from the date of delivery, ensuring peace of mind for our clients. Our dedicated quality assurance team is always available to address any concerns or provide support.

Customer Support and Technical Assistance

Our commitment to customer success is paramount. Hezhen's technical support team comprises experienced chemists and application specialists who can provide expert guidance on pigment selection, formulation optimization, dispersion techniques, and troubleshooting. Whether it's a query about product compatibility, regulatory compliance, or optimizing color development, our team is ready to offer prompt and effective assistance. We offer dedicated account managers to ensure personalized service and continuous support throughout the customer journey.

Conclusion: The Future is Polychromatic

The Hezhen polychromatic iron oxide pigment for coating painting rubber is more than just a coloring agent; it is a testament to advanced material science and engineering, offering unparalleled aesthetic appeal combined with robust functional performance. Its ability to provide dynamic, multi-dimensional colors, coupled with superior lightfastness, weatherability, and eco-friendly attributes, positions it as a leading choice for the next generation of paints, coatings, and rubber products. As industries continue to seek innovative solutions that blend beauty with durability and sustainability, Hezhen's commitment to quality, customization, and customer support ensures that it remains at the forefront of pigment technology, helping clients unlock new possibilities in product design and performance.

For further insights into the science of iron oxide pigments and their applications, consider exploring resources from reputable organizations and academic journals:

- Pigment Manufacturers Association (PMA) technical papers: https://www.pigments.org.uk/

- Journal of Coatings Technology and Research (JCTR): https://link.springer.com/journal/11998

- American Chemical Society (ACS) publications on materials science: https://pubs.acs.org/

- European Association of Pigment Manufacturers (CEPE): https://www.cepe.org/