- Introduction to Fe2O3 Pigments

- Technical Advantages & Performance Metrics

- Market-Leading Manufacturers: A Data-Driven Comparison

- Customized Solutions for Industry-Specific Needs

- Innovative Applications in Modern Industries

- Environmental Compliance & Safety Standards

- Future Trends in Iron Oxide Pigment Utilization

(fe2o3 pigment)

Understanding Fe2O3 Pigment and Its Industrial Significance

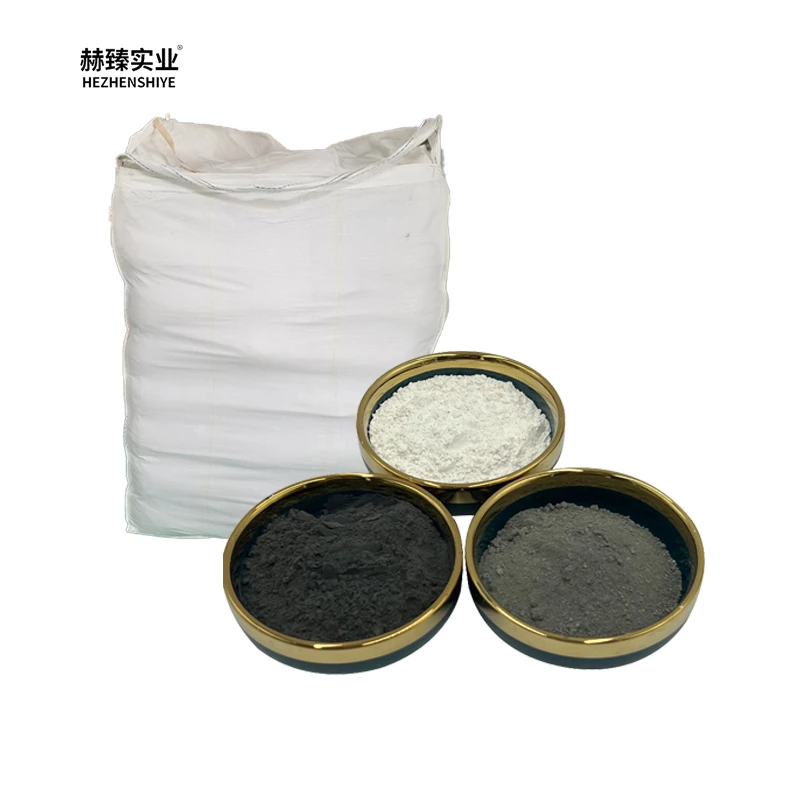

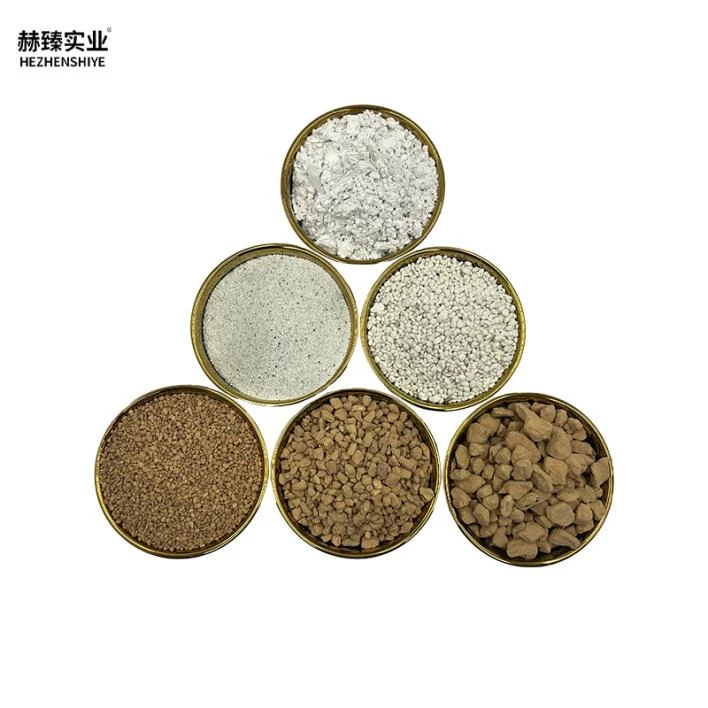

Fe2O3 pigment, a critical inorganic compound, dominates global markets due to its exceptional lightfastness, chemical stability, and cost efficiency. With a CAGR of 4.8% projected through 2030 (Grand View Research), demand spans construction (38%), coatings (29%), and plastics (18%) sectors. This iron-based colorant exists in multiple forms, including green and black variants, meeting diverse industrial chromatic requirements while maintaining non-toxic properties.

Technical Superiority in Pigment Engineering

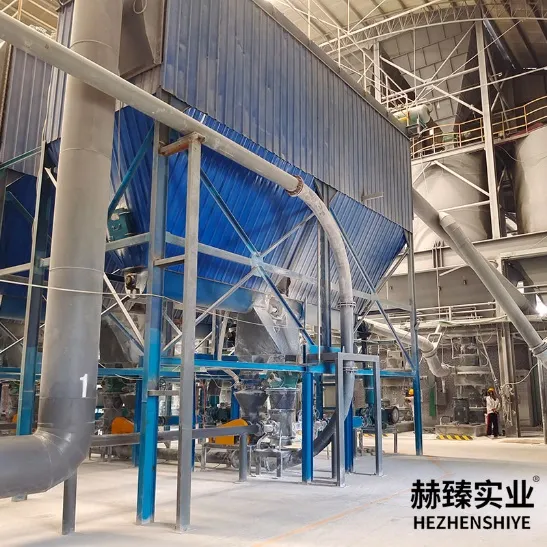

Advanced manufacturing processes enable particle size control between 0.2-5μm, achieving 98%+ color consistency. Key performance metrics include:

| Parameter | Fe2O3 Green | Fe2O3 Black | Industry Average |

|---|---|---|---|

| Heat Resistance (°C) | 500 | 450 | 380 |

| Oil Absorption (g/100g) | 18-22 | 20-25 | 25-30 |

| pH Stability | 5-9 | 4-10 | 6-8 |

Competitive Landscape Analysis

A 2023 market study reveals distinct manufacturer profiles:

| Manufacturer | Production Capacity (kT/yr) | Color Range | Certifications |

|---|---|---|---|

| PigmentCorp | 120 | 12 Standard | ISO 9001, REACH |

| Chromatech | 85 | 8 Standard | EPA Tier IV |

| OxideSolutions | 150 | 15+ Custom | ISO 14001 |

Tailored Formulation Development

Specialized pigment systems address specific challenges:

- UV-resistant grades for exterior architectural coatings

- Low-moisture variants for polymer compounding

- High-purity (>99.8%) batches for food-contact plastics

Cross-Industry Implementation Cases

Recent successful deployments include:

- Automotive OEMs: 15% weight reduction using pigment-loaded composites

- Infrastructure Projects: 25-year color warranty concrete formulations

- Consumer Electronics: EMI-shielding composite housings

Regulatory Compliance Framework

Leading producers now implement:

| Standard | Test Method | Compliance Level |

|---|---|---|

| ASTM D-685 | Lead Content | <1 ppm |

| EN 71-3 | Heavy Metals | Class 0 |

Fe2O3 Pigment: Driving Sustainable Color Solutions

With 73% of global manufacturers now requiring eco-certified pigments (ChemQuest 2023), Fe2O3 variants deliver unmatched sustainability. Recent breakthroughs in nanoparticle engineering (40-60nm particles) enable 22% reduction in material usage while maintaining chromatic intensity, positioning iron oxide pigments as the cornerstone of industrial coloration strategies.

(fe2o3 pigment)

FAQS on fe2o3 pigment

Q: What are common applications of Fe2O3 pigment?

A: Fe2O3 pigment is widely used in coatings, concrete, plastics, and ceramics due to its excellent color stability and weather resistance. It also serves as a cost-effective coloring agent in construction materials.

Q: How does iron oxide green pigment differ from Fe2O3 pigment?

A: Iron oxide green pigment is typically a blend of Fe2O3 with other metal oxides like chromium, while pure Fe2O3 pigment is red or brown. The green variant offers unique hues for niche applications like specialty paints and art supplies.

Q: Is iron oxide pigment black safe for cosmetic use?

A: Yes, iron oxide pigment black (Fe3O4) is non-toxic and approved by regulatory agencies for cosmetics. It's commonly used in makeup, soaps, and skincare products for its stable coloration.

Q: Which industries primarily use iron oxide pigments?

A: Key industries include construction (concrete coloring), automotive (coatings), cosmetics, and arts. Black and green variants are especially popular in industrial coatings and artistic materials.

Q: Can Fe2O3 pigments withstand high temperatures?

A: Yes, Fe2O3 pigments exhibit strong thermal stability, making them suitable for high-temperature applications like ceramic glazes and industrial coatings. Their performance depends on particle size and processing methods.