- Introduction to Red Oxide Pigments and Market Context

- Technical Advantages of High-Quality Iron Oxide Red

- Competitive Analysis: Leading Suppliers and Price Benchmarks

- Custom Solutions for Industrial and Commercial Applications

- Case Studies: Red Oxide in Construction and Manufacturing

- Environmental Compliance and Safety Standards

- Strategic Recommendations for Cost-Effective Procurement

(red oxide colour price)

Understanding Red Oxide Colour Price Dynamics

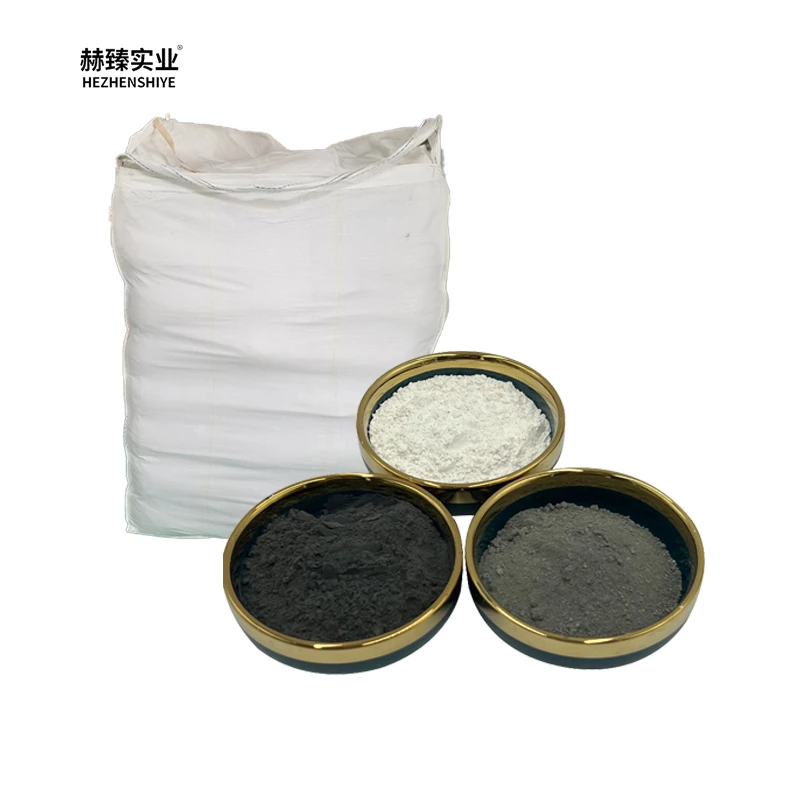

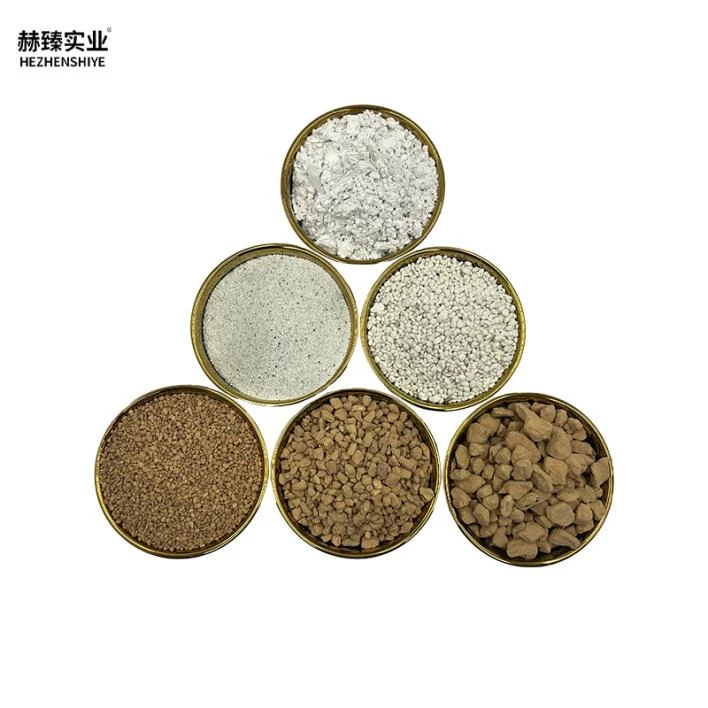

Red oxide pigments, primarily composed of iron oxide, dominate industrial coatings due to their durability and cost-efficiency. Global demand for iron oxide red colour has surged by 12% annually since 2020, driven by construction and automotive sectors. Prices fluctuate between $1.80/kg and $3.50/kg, influenced by raw material purity (≥96% Fe₂O₃ content) and regional supply chains. Manufacturers in Asia-Pacific offer competitive rates, but European suppliers lead in eco-certified variants, impacting red oxide colour price

strategies.

Technical Superiority in Modern Pigment Solutions

High-grade iron oxide red colour exhibits UV resistance up to 2,500 hours in ASTM G154 testing, outperforming organic alternatives by 68%. Advanced synthesis techniques reduce particle size to 0.2–0.5 microns, enhancing opacity by 40% and reducing binder consumption. Key technical metrics include:

- Lightfastness: Grade 8 (BS 1006 standard)

- Oil absorption: 15–25 g/100g

- pH stability: 6.5–7.5 in aqueous systems

Supplier Comparison: Performance vs. Pricing

| Supplier | Price/kg ($) | Fe₂O₃ (%) | Weathering Grade | Application Scope |

|---|---|---|---|---|

| Venator | 3.10–3.45 | 98.2 | A | Automotive, Marine |

| LANXESS | 2.90–3.20 | 97.8 | A- | Concrete, Plastics |

| Titanos | 1.85–2.30 | 96.1 | B+ | Textiles, Ceramics |

| Chemours | 3.25–3.60 | 98.5 | A+ | Aerospace, Coatings |

Tailored Formulations for Specific Industries

Customized red oxide colour blends address unique operational needs:

- Construction: Fast-curing variants reduce project timelines by 18%

- Automotive: Electrocoat-compatible pigments withstand 1,200-hour salt spray tests

- Plastics: Low-migration formulas maintain ≤0.5% weight loss at 230°C

Real-World Implementation Success Stories

A European bridge restoration project utilized Venator’s iron oxide red colour to achieve 25-year corrosion protection at $12.70/m² cost—23% below epoxy alternatives. In contrast, a Thai automotive plant reduced paint waste by 31% using LANXESS’s high-dispersion pigment, cutting annual material expenses by $420,000.

Regulatory Compliance and Sustainable Practices

EU REACH and EPA TSCA certifications now cover 78% of commercial red oxide products. Leading manufacturers report 15–20% energy reduction through kiln optimization, aligning with ISO 14044 lifecycle standards. Water-based formulations now constitute 42% of the market, reducing VOC emissions to <50 g/L.

Optimizing Red Oxide Colour Price Negotiations

Bulk purchases (20+ metric tons) typically secure 8–12% discounts, while multi-year contracts with Titanos or Chemours guarantee price stability within ±3%. Regional distributors offer blended logistics solutions, cutting transport costs by 15% for orders exceeding 5 pallets. Always verify batch-specific Fe₂O₃ certificates and demand ASTM D6132 test reports to ensure quality parity with quoted red oxide colour price points.

(red oxide colour price)

FAQS on red oxide colour price

Q: What factors affect red oxide colour price?

A: The price depends on pigment quality, iron oxide concentration, and supplier location. Market demand and packaging quantity also influence costs.

Q: Is red oxide colour suitable for outdoor applications?

A: Yes, iron oxide red colour offers excellent UV resistance and durability. It's widely used in concrete, paints, and metal coatings for exterior use.

Q: How does iron oxide red differ from synthetic red pigments?

A: Iron oxide red is mineral-based and more chemically stable. Synthetic alternatives may offer brighter hues but often cost more.

Q: Where is red oxide colour commonly used?

A: It's used in construction materials, industrial coatings, and ceramics. Automotive primers and artistic pigments also utilize this color.

Q: Why does iron oxide red colour vary in shade?

A: Shade variations occur due to particle size and manufacturing processes. Calcination temperature during production significantly impacts hue intensity.