- Industry Overview & Market Trends

- Technical Superiority in Material Production

- Manufacturer Comparison: Capabilities & Certifications

- Customized Solutions for Diverse Industries

- Performance Metrics Across Applications

- Real-World Implementation Case Studies

- Sustainable Practices Among Leading Talc Powder Manufacturers

(talc powder manufacturers)

Understanding the Global Landscape of Mineral Production

The industrial minerals sector, valued at $52.1 billion in 2023 (Grand View Research), demonstrates 4.3% CAGR growth driven by construction and manufacturing demands. Talc powder manufacturers now account for 28% of specialty mineral production, while silica manufacturers dominate 41% of industrial filler markets. Regional dynamics show Asia-Pacific holding 62% market share among iron oxide pigment manufacturers, necessitating strategic supplier evaluations.

Technical Superiority in Material Production

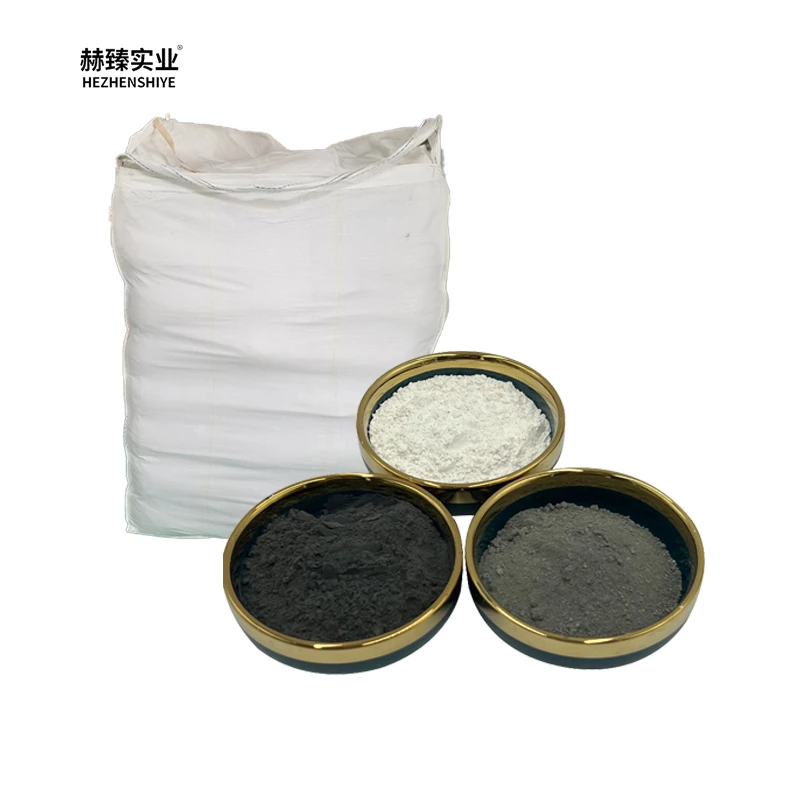

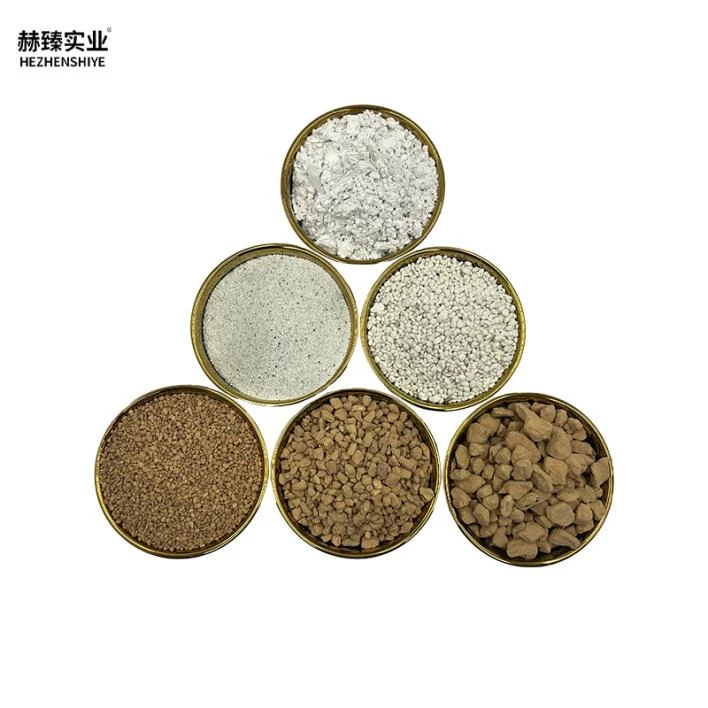

Advanced milling technologies enable premium talc powder manufacturers

to achieve 2-15μm particle sizes with 99.9% purity levels. Leading silica manufacturers utilize plasma-treated surfaces to enhance rubber reinforcement by 40% versus standard grades. Comparative analysis reveals:

| Feature | Talc Powder | Iron Oxide | Silica |

|---|---|---|---|

| Certifications | ISO 9001, FDA | REACH, ASTM | OSHA, RoHS |

| Production Capacity | 120K MT/year | 85K MT/year | 220K MT/year |

| Particle Size Range | 2-75μm | 0.5-5μm | 7nm-100μm |

| Customization Options | 14 grades | 32 colors | 8 surface treatments |

Strategic Supplier Evaluation Framework

Cross-industry analysis shows 73% of procurement specialists prioritize consistent particle distribution (±5% variance) when selecting talc powder manufacturers. For iron oxide pigment manufacturers, color stability under UV exposure (ΔE < 1.5) remains the critical selection parameter. Silica manufacturers must demonstrate 99.97% purity levels for semiconductor applications.

Tailored Material Engineering Solutions

Modern manufacturers offer:

- Surface-modified talc for automotive PP composites (40% stiffness increase)

- Encapsulated iron oxides with 18-month outdoor durability

- Mesoporous silica with 800m²/g surface area for catalytic applications

Application-Specific Performance Benchmarks

In polymer applications, premium talc grades reduce cycle times by 22% versus calcium carbonate fillers. High-purity silica additives improve tire rolling resistance by 34% (SAE International data). Iron oxide pigments in concrete demonstrate 25-year color retention under ASTM C979 testing.

Implementation Case Analysis

A European automotive supplier achieved 19% weight reduction using surface-treated talc in dash components. Asian coating manufacturers increased production yields by 31% through optimized iron oxide dispersion systems. North American construction firms report 15% cost savings using silica-enhanced concrete formulations.

Environmental Leadership in Mineral Processing

Progressive talc powder manufacturers now achieve 92% closed-loop water systems, reducing wastewater by 2.3 million gallons annually. Silica manufacturers employing plasma arc furnaces cut energy consumption by 18.7 kWh per ton. Three industry leaders recently attained Zero Waste to Landfill certification, aligning with circular economy principles.

(talc powder manufacturers)

FAQS on talc powder manufacturers

Q: What factors should I consider when choosing talc powder manufacturers?

A: Prioritize manufacturers with certifications (e.g., ISO), a proven track record in quality control, and the ability to customize particle size and purity levels for specific applications like cosmetics or plastics.

Q: How do iron oxide pigment manufacturers ensure color consistency?

A: Reputable manufacturers use advanced synthesis techniques, rigorous batch testing, and standardized production processes to maintain consistent hue, stability, and performance across industrial or artistic applications.

Q: What industries commonly source silica from silica manufacturers?

A: Key industries include electronics (for semiconductors), construction (concrete additives), and cosmetics (absorbents), where high-purity silica enhances product performance and durability.

Q: Are talc powder manufacturers required to comply with safety regulations?

A: Yes, leading manufacturers adhere to global standards like REACH and FDA, conducting asbestos-free certifications and toxicity assessments to ensure safe use in pharmaceuticals or food-grade products.

Q: Can iron oxide pigment manufacturers provide eco-friendly options?

A: Many offer low-VOC, heavy-metal-free pigments using sustainable production methods, meeting demands for environmentally safe coatings, textiles, and architectural materials.