Présentation du produit

White carbon black is a general term for white powdered X-ray amorphous silicic acid and silicate products. The following is a detailed introduction of white carbon black:

1.Definition and chemical composition

Definition: White carbon black, chemically known as silica (SiO₂), is a white, non-toxic, amorphous powder that is a highly dispersed nanoscale nonmetallic material. It is named because of its white appearance and can be used as a substitute for carbon black.

Chemical composition: white carbon black is a porous substance, and its composition can be expressed by SiO₂·nH₂O, where nH₂O is in the form of a surface hydroxyl group.

2.Physical and chemical properties

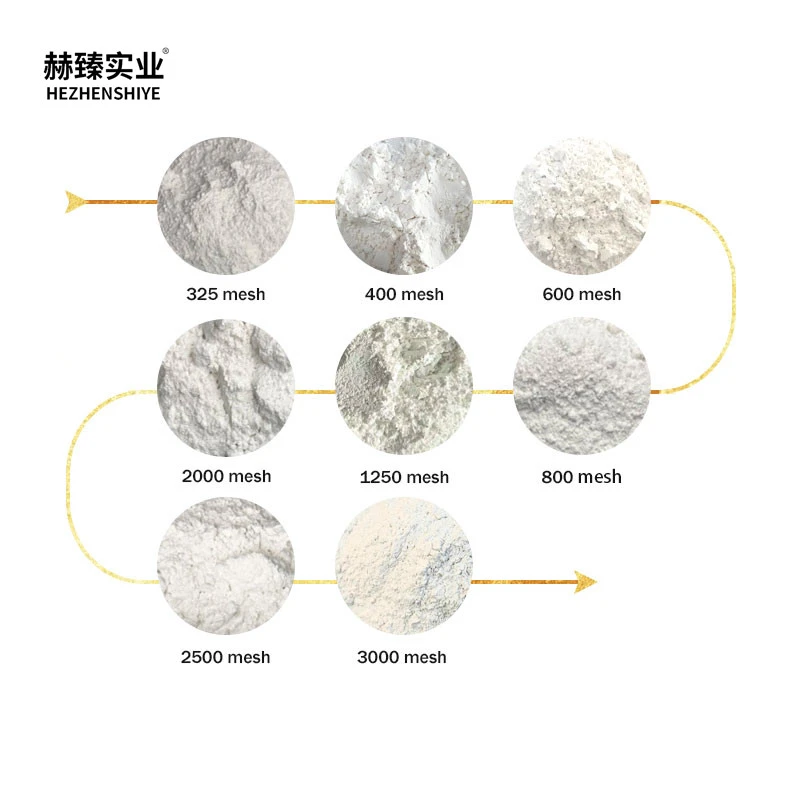

Physical properties: silica crystal is a hard, brittle, non-conductive, refractory (melting point 1710℃) and insoluble in water colorless solid. Its apparent density is 0.128g/cm³.

Chemical properties: silica black is an anhydride of silicic acid and cannot react with water to produce silicic acid. Because the silicon-oxygen bond is strong, the chemical properties are very stable. At high temperature, it can react with basic oxide, alkali, soda ash and so on to form silicate. White carbon black does not react with ordinary acids, has good acid resistance, but can be corroded by hydrofluoric acid.

3. Production methods

Precipitation method: Reaction of sodium silicate solution with acid to form silica colloid, after drying and sintering, white carbon black is obtained. It is divided into traditional precipitation method and special precipitation method, the former refers to the silica produced by sulfuric acid, hydrochloric acid, CO₂ and water glass as the basic raw materials, the latter refers to the silica produced by special methods such as super gravity technology, sol-gel method, chemical crystal method, secondary crystallization method or reversed-phase micelle microemulsion method.

Vapor phase method: silane or siloxane is decomposed at high temperature to generate silicon nanoparticles, which are collected and dried to obtain white carbon black. Fumed white carbon black is all nano silica, the purity of the product can reach 99%, the particle size can reach 10~20nm, but the preparation process is complex and expensive.

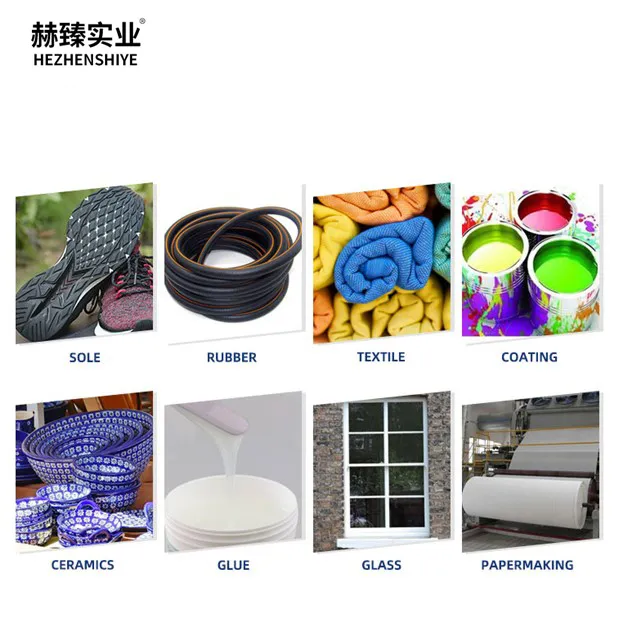

4. Application field

Rubber industry: rubber reinforcing agent is its largest downstream application, the amount accounts for more than 75% of the total amount, to improve the strength of rubber, wear resistance, aging resistance and other properties.

Coating industry: Used to prepare high-performance coatings, improve the adhesion, hardness, wear resistance and other properties of the coating.

Plastics industry: as a plastic filler, improve the strength of plastics, wear resistance, aging resistance and other properties.

Catalyst carrier: with large specific surface area and activity, it can be used as a catalyst carrier to improve the performance of the catalyst.

Environmental protection: Used as an adsorbent to effectively remove harmful substances from water, and can also be used in photocatalytic reactions to degrade pollutants in air and water.

Biomedical: With good biocompatibility, it can be used to prepare biomedical materials, such as scaffolds, bone replacement materials, and drug carriers.

Food processing: As a food additive, improve the taste and stability of food.

Paper industry: can improve the whiteness, smoothness and gloss of paper, improve the printing performance of paper.

Ink industry: It can improve the hiding power, adhesion and stability of ink, and improve the printing performance of ink.

Cosmetics industry: It can improve the fineness, stability and sense of use of cosmetics, regulate skin oil secretion, and improve skin quality.

Pharmaceutical industry: Used in the preparation of pharmaceutical preparations, it can improve the dispersion, stability and bioavailability of drugs, and reduce the side effects of drugs.

5. Market trends

With the recovery of market demand and the recovery of the price system, the market size of precipitated white carbon black in China has returned to an upward trend, and it is expected to maintain a continuous upward trend.

The market sales of highly dispersed white carbon black production enterprises with strong research and development ability and leading products will be further expanded. In the carbon black industry, brand awareness and reputation is one of the key factors for manufacturers to compete.

| Numéro de dossier | 112945-52-5 |

| Lieu d'origine | Chine |

| Couleur | Blanc |

| Forme | Poudre |

| Pureté | 95-99% |

| Grade | qualité industrielle |

| Emballer | 10-25 kg/sac, emballage personnalisé |

| Quantité minimale de commande | 1 kg |

Bannière PDF

Bannière PDF Obtenir un devis

Obtenir un devis