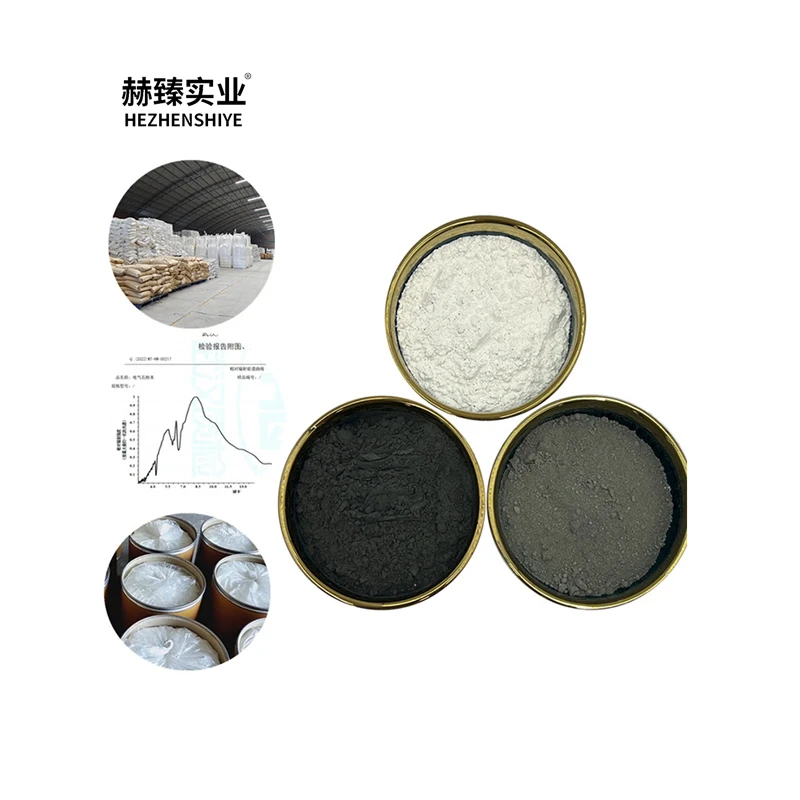

Kaolin powder for rubber industry cosmetics industry paper making products ceramics additive

2025.05.07

Kaolin is the lifeblood of the ceramics industry. In porcelain production, it serves as a fundamental raw material for making the body of porcelain items. Its high - quality properties contribute to the fine grained, smooth texture and high - strength characteristics of porcelain. The pure white color of kaolin also enhances the whiteness of porcelain, making it more aesthetically pleasing. For example, in the production of delicate porcelain tableware and decorative vases, kaolin plays a crucial role. In the manufacturing of ceramic tiles, kaolin is added to improve the tile's mechanical strength, ensuring durability during use. It also helps in achieving a smooth surface finish, which is essential for both the appearance and functionality of tiles, especially in high - traffic areas.

In the paper making process, kaolin is used in two main ways: as a filler and a coating. As a filler, kaolin is mixed with cellulose fibers. It helps to increase the opacity of the paper, making it less transparent and more suitable for printing. Kaolin also improves the paper's smoothness, which in turn enhances the printability. When used as a coating, it is applied to the paper surface along with an adhesive. This coating layer provides a glossy finish, improves color retention, and further enhances the paper's ability to hold ink, resulting in high - quality printed materials such as magazines, brochures, and high end packaging papers.

For the rubber industry, kaolin acts as a reinforcing filler. It significantly improves the mechanical properties of rubber, such as tensile strength, tear resistance, and abrasion resistance. By adding kaolin, rubber products like tires, conveyor belts, and seals can better withstand harsh operating conditions, extending their service life. In the plastics industry, kaolin is used as an additive to enhance the rigidity and dimensional stability of plastic products. It also improves the surface finish of plastics, making them more suitable for applications where appearance matters, such as in consumer electronics and automotive interior parts.

In cosmetics, kaolin is widely used for its absorbent and texture - improving properties. It is a common ingredient in face powders, where it helps to control oil on the skin, providing a matte finish. Kaolin also finds its way into facial masks, where it can draw out impurities from the pores, leaving the skin feeling clean and refreshed. In the pharmaceutical field, kaolin is used as an excipient in tablet formulations. It helps in binding the active ingredients together, ensuring the proper shape and integrity of tablets. Additionally, kaolin has some adsorbent properties, which can be useful in certain medications for treating digestive issues.