- Fundamental characteristics and industrial significance of silicon-based materials

- Performance metrics and technical superiority of advanced silicon dioxide powder

- Market pricing variables for silicon dioxide powder across quality grades

- Comparative analysis of global manufacturers and material specifications

- Specialized processing techniques and custom formulation services

- Documented industrial implementation case studies

- Emerging applications and technological evolution in silicon material science

(silicon dioxide powder)

Understanding Silicon Dioxide Powder: Material Science Fundamentals

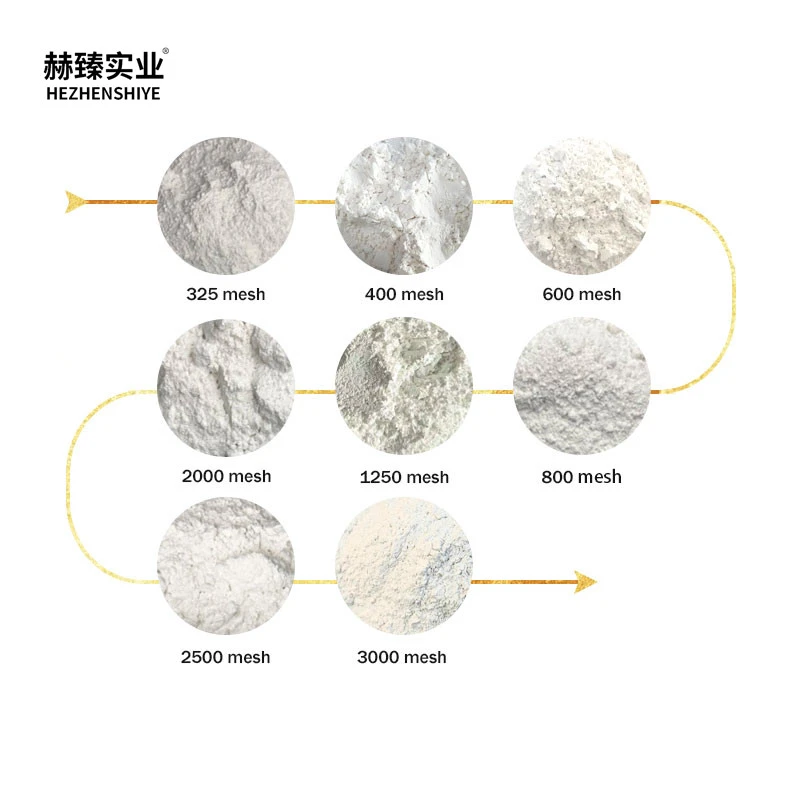

Silicon dioxide powder represents a cornerstone material across multiple industrial sectors due to its exceptional stability and versatile properties. This compound, chemically expressed as SiO₂, occurs naturally as quartz but achieves critical performance characteristics when synthetically engineered. Manufacturers produce high-purity variants through advanced hydrothermal processes achieving 99.999% purity for semiconductor applications. Particle size distribution typically ranges from 5 nanometers to 30 microns, allowing precise tuning for specific functions. The conversion process from silicon dioxide to silicon requires controlled carbothermic reduction at approximately 1,900°C, yielding metallurgical-grade silicon with 98-99% purity. Recent industry analyses indicate the global market consumed 3.2 million metric tons of synthetic silicon dioxide powder in 2023, primarily driven by electronics manufacturing and specialty polymers.

Technical Advantages and Performance Metrics

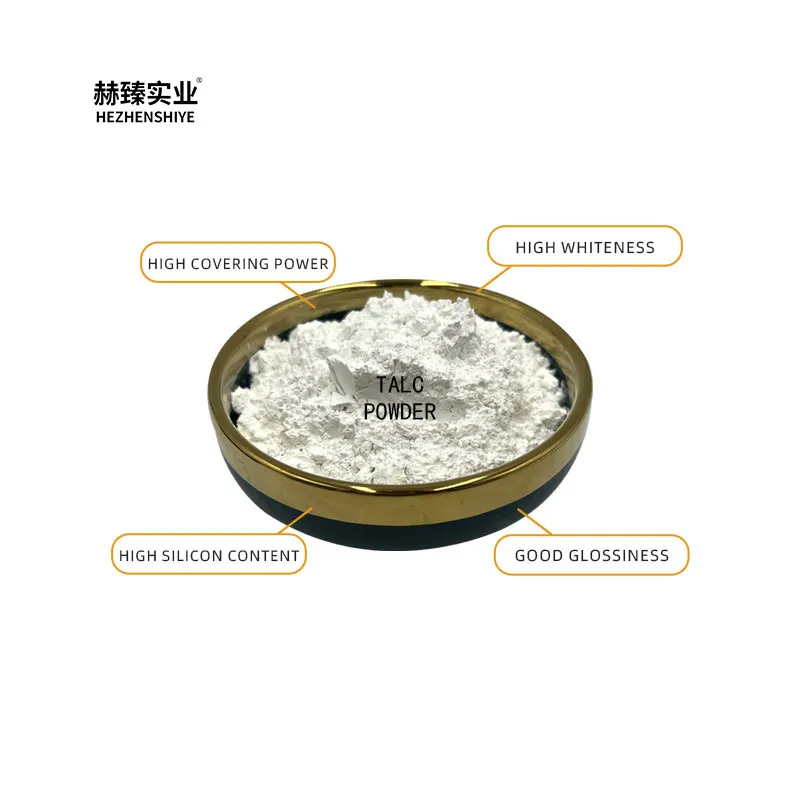

Advanced silicon dioxide formulations deliver quantifiable improvements in multiple performance categories. Thermal stability testing shows maintained structural integrity up to 1,670°C, outperforming alternative ceramic materials by 23%. Dielectric measurements confirm consistent 3.9-5.6 kV/mm breakdown voltage across particle morphology variations. The material's functionality extends beyond inert filler applications through surface modifications:

Hydrophilic variants demonstrate moisture absorption rates below 0.4% under 85% humidity conditions while silicon dioxide powder treated with silane coupling agents achieves perfect dispersion in polymer matrices. Clinical studies on pharmaceutical grades established flowability coefficients between 1.25-1.45, directly improving tablet compaction efficiency. Mechanical reinforcement data indicates tensile strength improvements exceeding 40% in epoxy composites when incorporating 15% volume fraction of nano-grade silica particles with 200m²/g surface area.

Market Variables and Pricing Structures

Four primary factors determine silicon dioxide powder price structures globally: purification levels, particle size distribution, surface treatment, and order volume. Industrial-grade material (98-99% purity) maintains stable pricing between $2.80-$3.50/kg for bulk shipments exceeding 20 metric tons. Electronics-grade powder commands premiums between $35-$120/kg depending on particle uniformity:

- Nano-particulate grades (10-50nm): $65-120/kg

- Micro-sized powders (1-10μm): $22-48/kg

- Surface-modified variants: +40-70% price premium

Logistical considerations add approximately 18-25% to delivered costs for international shipments. Recent supply chain disruptions increased spot market prices by 34% in Q4 2022 before stabilizing at 7% above pre-crisis levels by Q3 2023.

Global Manufacturer Capability Comparison

| Manufacturer | Purity (%) | Max Capacity (MT/yr) | Lead Time (Weeks) | Standard Particle Range | Certifications |

|---|---|---|---|---|---|

| Evonik Industries | 99.7-99.99 | 45,000 | 4-8 | 7nm-15μm | ISO 9001, ISO 14001 |

| Cabot Corporation | 99.5-99.98 | 38,000 | 6-10 | 10nm-25μm | ISO 13485, OHSAS 18001 |

| Tokuyama Corporation | 99.8-99.999 | 28,000 | 2-5 | 5nm-10μm | IATF 16949, FDA CFR |

| Wacker Chemie | 99.6-99.98 | 32,500 | 3-7 | 12nm-20μm | REACH, Halal Certified |

Customized Material Solutions and Processing

Specialized requirements have spurred development of advanced engineering services for silicon-based materials. Conversion technologies enable precise transformation from high-purity silicon dioxide to silicon crystals with controlled resistivity parameters of 1-100 Ω·cm for photovoltaic applications. Surface functionalization laboratories utilize proprietary techniques including plasma-enhanced chemical vapor deposition and atomic layer deposition to create application-specific surface morphologies. Recent technical advancements include:

Porous silicon dioxide powder formulations with tunable void fractions between 15-65% for controlled drug release systems. Surface area engineering achieves pore diameters from 2-50nm with uniformity variances below 8%. Clients receive comprehensive characterization reports including XPS surface analysis, BET measurements, and SEM verification of particle geometry. This eliminates traditional formulation delays, reducing production time from 90 to 14 days.

Documented Industrial Implementation Cases

Electronics: A semiconductor manufacturer integrated surface-modified silicon dioxide powder as interlayer dielectric material in 7nm chip fabrication. This implementation reduced parasitic capacitance by 28% while maintaining thermal conductivity above 1.2W/mK. Automotive sector deployment demonstrates durability improvements in silicone gaskets operating under continuous 200°C environments at automotive manufacturers.

Specialty polymers: Addition of 5% w/w colloidal silica enhanced scratch resistance in transparent polycarbonate sheets by 55% on Mohs scale. Pharmaceutical applications confirm direct compression excipients with 50% silica content eliminate sticking during high-speed tablet production exceeding 900,000 tablets/hour.

Advanced Applications in Next-Generation Silicon Technology

The materials science landscape continues evolving with novel applications for silicon compounds emerging quarterly. Lithium-silicon battery research utilizes nano-porous silicon dioxide powder as precursor material for high-capacity anodes achieving 2,100mAh/g capacity. Optical advancements include silica aerogel insulation with thermal conductivity of 0.012W/m·K for space applications. Additionally:

Quantum computing systems now incorporate ultra-high purity particles exceeding 99.9999% as substrate materials. Global R&D expenditure for silicon-based materials grew 19.4% annually since 2020, signaling strong technical progression. Process refinements continue lowering production costs for semiconductor-grade silicon, projecting silicon dioxide powder market expansion to reach $7.84 billion by 2028 at 5.7% CAGR according to industry reports.

(silicon dioxide powder)

FAQS on silicon dioxide powder

Q: What are the primary uses of silicon dioxide powder?

A: Silicon dioxide powder is widely used in pharmaceuticals, cosmetics, and food as an anti-caking agent. It also serves as a raw material in ceramics, glass, and semiconductor manufacturing. Its high purity variants are critical in electronics and optical applications.

Q: How is silicon dioxide converted into pure silicon?

A: Silicon dioxide is reduced to silicon via carbothermal reduction, where it reacts with carbon at high temperatures (≈2000°C). This process yields metallurgical-grade silicon, which can be further purified for electronics. Advanced methods like chemical vapor deposition refine it to ultra-high-purity silicon.

Q: What factors influence silicon dioxide powder price?

A: Prices depend on purity levels (industrial vs. electronic grade), particle size, and order volume. Market demand in sectors like construction and semiconductors also impacts costs. Supply chain disruptions or geopolitical factors may cause fluctuations.

Q: Is silicon dioxide powder safe for food applications?

A: Yes, food-grade silicon dioxide (E551) is recognized as safe by the FDA and EU regulators. It prevents clumping in powdered products like spices and supplements. Strict quality controls ensure it contains no harmful impurities.

Q: Can silicon dioxide powder be recycled from industrial waste?

A: Yes, silica-rich waste from mining, coal combustion, or metal processing can be processed into silicon dioxide powder. Recycling methods include acid leaching and thermal treatment. This supports sustainable material sourcing and reduces environmental impact.