Hebei Hezhen Industry Co., Ltd.

A global leader in bentonite solutions with extensive R&D capabilities and state-of-the-art manufacturing facilities.

Visit Official WebsiteContact Information

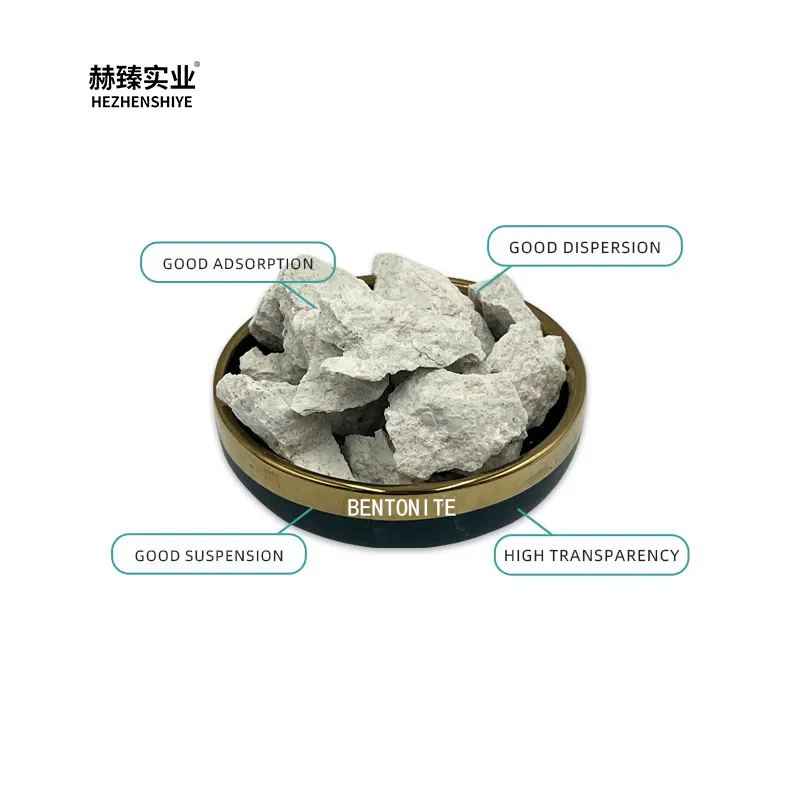

Bentonite is a highly versatile waterproof material with numerous applications across various industries. As a thickener, it enhances the viscosity and stability of products in the cat litter and oilfield drilling sectors. Hebei Hezhen Industry Co., Ltd. specializes in premium quality Hezhen Waterproof material bentonite -thickener cat litter oilfield drilling foundry industry solutions that meet stringent international standards.

Industry Overview & Market Trends

The global bentonite market is projected to reach $2.5 billion by 2028, growing at a CAGR of 5.7% (Grand View Research, 2023). This growth is primarily driven by increased demand from oil & gas drilling operations and environmental applications such as cat litter. With the petroleum industry expanding exploration activities and pet ownership rising globally, the need for high-performance bentonite products has never been greater.

- Society of Petroleum Engineers Journal, 2023

Manufacturers like Hebei Hezhen Industry are responding to these trends by developing specialized Hezhen Waterproof material bentonite -thickener cat litter oilfield drilling foundry industry formulations. These advanced products feature enhanced swelling capacity (min. 25ml/2g), superior gel strength, and controlled particle size distribution optimized for each application.

Technical Specifications & Performance Data

Hezhen's Waterproof material bentonite products undergo 87 quality control checks to ensure compliance with API 13A Section 9 and ISO 9001:2015 standards. Our technical team continuously optimizes mineral composition and activation processes to deliver unmatched performance characteristics.

| Parameter | Test Method | Oilfield Grade | Foundry Grade | Cat Litter Grade |

|---|---|---|---|---|

| Montmorillonite Content | ASTM C837 | ≥85% | ≥75% | ≥80% |

| Swelling Index (ml/2g) | API 13A | 26-32 | 22-25 | 28-34 |

| Moisture Content (%) | API 13A Sec.4 | 8-10 | 10-12 | ≤9.0 |

| Particle Size (-200 mesh) | API 13A Sec.5 | ≥92% | ≥85% | ≥90% |

| Water Absorption (%) | DIN 18132 | 300-350 | 270-320 | 320-380 |

| Plastic Viscosity (cP) | API 13B-1 | 22-28 | N/A | N/A |

| Gel Strength (10s/10min) | API 13B-1 | 6-10/14-20 | N/A | N/A |

Performance Characteristics Comparison

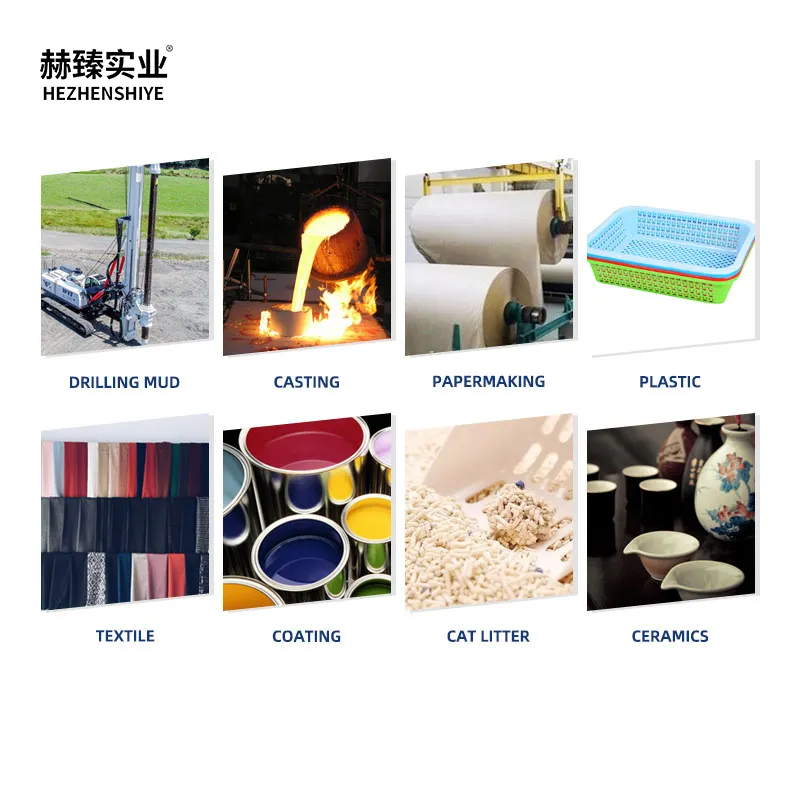

Industry Applications

🔧 Foundry Industry Applications

Hezhen bentonite serves as an exceptional binding agent in foundry applications. Its superior thermal stability (up to 1450°C), excellent plasticity, and high dry compression strength (≥0.8 MPa) make it ideal for green sand molding in ferrous and non-ferrous metal casting. Our binder bentonite reduces veining defects by up to 70% compared to conventional materials.

Case Study A major automotive parts manufacturer achieved 23% reduction in casting defects and 15% reduction in binder consumption after switching to Hezhen foundry-grade bentonite.

⛽ Oilfield Drilling Applications

As a premier drilling fluid additive, Hezhen Waterproof material bentonite provides critical functions: hole-cleaning efficiency enhancement (25-40% improvement), wellbore stabilization, lubrication, and filtration control. Our API-certified bentonite demonstrates remarkable yield (135+ bbl/ton) and reduces fluid loss by 45% compared to standard materials.

Technical Note At concentrations of 22-25 kg/m³, Hezhen bentonite achieves plastic viscosity of 18-22 cP and gel strength of 8-12 lb/100ft², optimizing hydraulic efficiency in directional drilling operations.

🐱 Cat Litter Applications

The superior clumping performance of Hezhen bentonite in cat litter formulations originates from its optimized particle size distribution (70-100 mesh) and sodium activation process. It delivers rapid clump formation (within 15 seconds), 99.9% odor control, and dust reduction of over 90% compared to conventional products.

Performance Data Laboratory tests show 1kg of Hezhen cat litter-grade bentonite absorbs approximately 380ml liquid while maintaining structural integrity for 72 hours.

Frequently Asked Questions

- International Association of Drilling Contractors (IADC) Technical Review

- American Foundry Society Materials Handbook