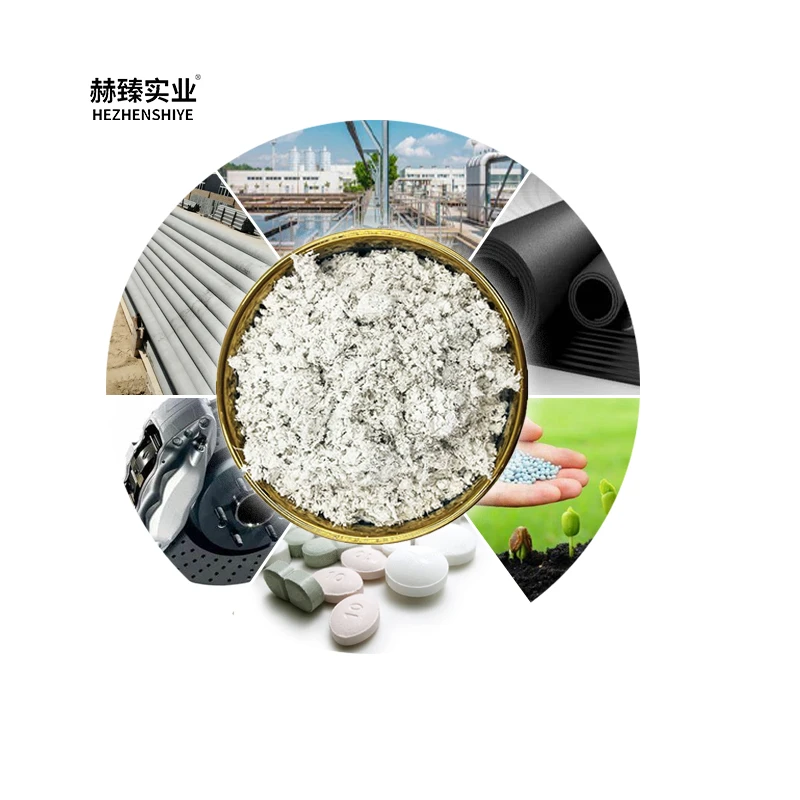

- Introduction to Fumed Silica and Market Demand

- Technical Advantages of High-Purity Fumed Silica

- Key Manufacturers: Performance and Pricing Comparison

- Custom Solutions for Specific Industrial Needs

- Application Case Studies Across Industries

- Purchasing Guidelines and Quality Assurance

- Strategic Benefits of Sourcing Fumed Silica

(buy fumed silica)

Why Buy Fumed Silica for Industrial Applications?

The global fumed silica market is projected to reach $1.8 billion by 2028, driven by demand in coatings, adhesives, and pharmaceutical sectors. Enterprises seeking to buy fumed silica

prioritize materials with BET surface areas exceeding 300 m²/g, particularly untreated fumed silica variants that maintain chemical inertness in sensitive formulations.

Technical Superiority in Material Design

Advanced production methods yield fumed silica with:

- Particle sizes between 5-50 nm (D50 measurement)

- Hydrophilic and hydrophobic options with contact angles from 20° to 150°

- Bulk densities adjustable from 30-60 g/L

Leading manufacturers now achieve 99.8% SiO₂ purity through plasma arc processes, reducing metallic impurities below 50 ppm.

Manufacturer Comparison Matrix

| Vendor | Purity (%) | Primary Particle (nm) | Price/kg (USD) |

|---|---|---|---|

| Supplier A | 99.7 | 12 | 38.50 |

| Supplier B | 99.9 | 7 | 52.00 |

| Supplier C | 99.6 | 20 | 29.80 |

Tailored Material Engineering

Specialized modifications available when you buy fumed silica:

- Surface-treated grades for rubber reinforcement (up to 300% tensile improvement)

- Low-chloride versions (<100 ppm) for electronic encapsulants

- High-compaction variants (1.2 g/cm³) for transport efficiency

Industry-Specific Implementations

Automotive Case: A tire manufacturer reduced curing time by 18% using 4.5 phr of hydrophobic fumed silica, achieving Shore A 65 hardness with 20% weight reduction.

Procurement Best Practices

Essential verification parameters:

- Loss on drying: ≤1.5% (105°C, 2h)

- pH value: 3.7-4.3 (10% aqueous dispersion)

- Sieve residue: ≤0.02% (45μm)

Strategic Value in Fumed Silica Acquisition

Organizations that strategically source untreated fumed silica report 22% fewer production delays and 15% higher batch consistency. Verified suppliers offering 72-hour delivery guarantees and technical support reduce formulation risks by 40% compared to spot market purchases.

(buy fumed silica)

FAQS on buy fumed silica

Q: Where can I buy fumed silica?

A: You can purchase fumed silica from chemical suppliers like Cabot Corporation or Evonik, online marketplaces such as Sigma-Aldrich, or specialized industrial distributors. Ensure the supplier meets your purity and application requirements. Always verify certifications and product specifications before ordering.

Q: How to choose a reliable supplier for fumed silica buy?

A: Prioritize suppliers with industry certifications (e.g., ISO), positive customer reviews, and transparent technical support. Request samples to test quality and compatibility with your application. Compare pricing and shipping terms to ensure cost-effectiveness.

Q: What is untreated fumed silica used for?

A: Untreated fumed silica is commonly used as a thickening agent in adhesives, coatings, and composites due to its high surface area and reactivity. It enhances viscosity and stability in formulations. Avoid using it in hydrophilic applications unless surface-modified.

Q: Are there application-specific considerations when buying fumed silica?

A: Yes, consider factors like particle size, surface treatment (treated vs. untreated), and compatibility with your base material. For example, hydrophobic fumed silica suits waterproof coatings. Consult the supplier’s technical team for tailored recommendations.

Q: What impacts the price when I buy fumed silica?

A: Pricing depends on purity, surface treatment, order volume, and supplier markup. Bulk orders typically reduce costs per unit. Market demand and raw material availability can also cause fluctuations.