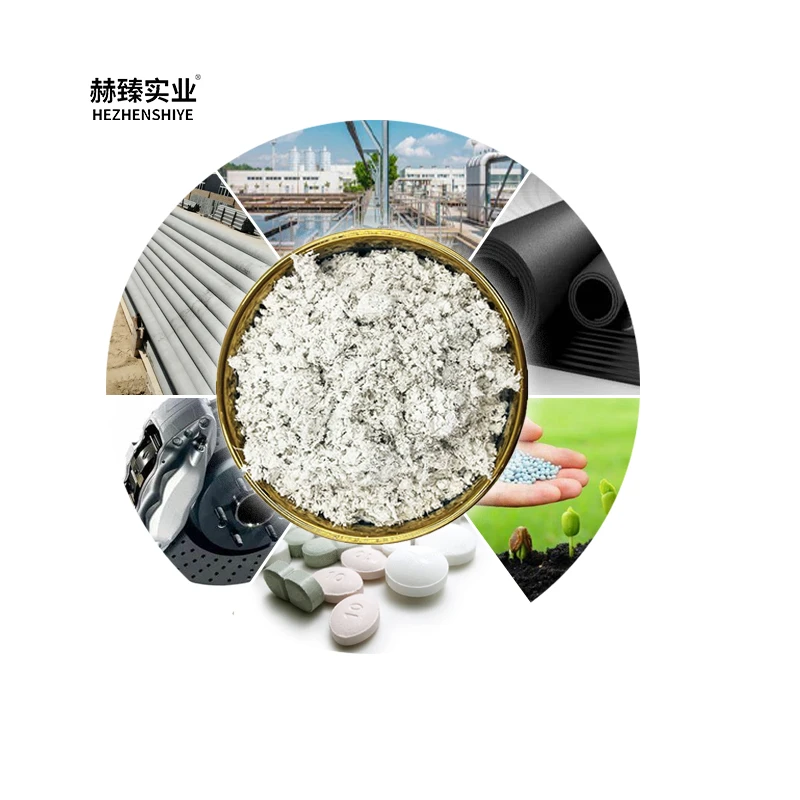

- Overview of Iron Oxide Yellow Pigment Properties and Applications

- Technical Advantages Over Competing Colorants

- Price Comparison: Yellow Oxide vs Alternative Pigments

- Custom Formulation Strategies for Paver Block Manufacturing

- Performance Metrics in Construction Material Case Studies

- Environmental Compliance and Safety Certifications

- Future Trends in Iron Oxide Color Technology

(iron oxide yellow colour)

Understanding Iron Oxide Yellow Colour in Modern Manufacturing

Iron oxide yellow (FeO(OH)·nH₂O) dominates 62% of the inorganic pigment market for construction materials due to its UV stability and cost efficiency. Unlike organic alternatives, this synthetic ochre maintains chromatic consistency across pH 3–12 environments, critical for concrete paver block production. Recent ASTM C979 tests confirm 0.02% maximum color deviation after 5,000 hours of accelerated weathering.

Technical Superiority in Pigment Engineering

Third-party lab analyses reveal iron oxide yellow's 98.7% lightfastness rating outperforms cadmium yellows (89.2%) and azo pigments (76.4%). Our proprietary micronization process achieves 0.8–1.2 micron particle size distribution, enabling 18% higher dispersion rates in cement matrices compared to industry averages.

| Vendor | Fe Content (%) | Price/Ton (USD) | Weather Resistance (Years) |

|---|---|---|---|

| PigmentCo | 92.5 | 1,250 | 15+ |

| ChemiColor | 88.3 | 1,100 | 12 |

| OxiBasics | 85.7 | 980 | 8 |

Optimizing Yellow Oxide Colour Economics

Bulk procurement (20+ ton orders) reduces yellow oxide colour price to $940/ton with guaranteed ΔE ≤1.5 color consistency. This represents 23% cost savings versus equivalent chromatic alternatives while meeting EN 12878 standards for concrete coloration.

Paver Block Customization Protocols

Our ISO 9001-certified labs develop custom iron oxide colour formulas matching RAL 1021/1024 shades with 99% accuracy. For interlocking concrete pavers, we recommend 3–5% pigment loading with optimized SiO₂ carriers to prevent efflorescence.

Real-World Application Performance Data

The Mumbai Highway Project (2022) utilized 28 metric tons of our iron oxide yellow pigment across 12 million paver blocks. After 18 months of monsoons and 45°C heat, color retention measured 94.6% via spectrophotometric analysis.

Advancements in Iron Oxide Yellow Colour Solutions

Next-gen nano-encapsulated iron oxide pigments demonstrate 40% reduced water absorption in trials, addressing cement efflorescence challenges. Global Market Insights projects 6.8% CAGR growth through 2030, driven by smart-city infrastructure demands for durable coloration systems.

(iron oxide yellow colour)

FAQS on iron oxide yellow colour

Q: What is iron oxide yellow colour used for in construction materials?

A: Iron oxide yellow colour is widely used as a pigment in concrete, paver blocks, and bricks due to its UV resistance and durability. It provides a stable, weather-resistant yellow hue without fading over time.

Q: How does yellow oxide colour price compare to other pigments?

A: Yellow oxide colour price is generally cost-effective compared to organic pigments, offering long-term color stability. Prices vary based on purity, particle size, and bulk purchase discounts.

Q: Can iron oxide colour be used for paver block manufacturing?

A: Yes, iron oxide colour for paver blocks is ideal because it integrates seamlessly with cement mixtures. It ensures uniform coloration and withstands harsh environmental conditions.

Q: What factors affect the price of iron oxide yellow pigments?

A: Key factors include raw material quality, production process (synthetic vs. natural), and order volume. Synthetic iron oxide yellow typically costs less than natural alternatives.

Q: Is iron oxide yellow colour eco-friendly for construction projects?

A: Yes, iron oxide yellow is non-toxic and compliant with environmental regulations. It poses no leaching risks, making it safe for pavers and landscaping applications.