Wollastonite Powder High Aspect Ratio Ceramic Filler for Tile Production Improve Mechanical Strength Reduce Firing Shrinkage Enhance Glaze Adhesion

2025.07.31

Wollastonite powder-based ceramics, such as floor and wall tiles, require a balance of strength, durability, and aesthetic appeal to meet market demands. Wollastonite powder has emerged as a critical ceramic filler, particularly in tile production, due to its unique acicular structure and chemical properties that enhance both manufacturing efficiency and end-product performance.

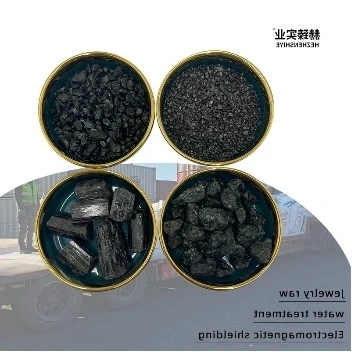

The high aspect ratio (length-to-diameter ratio) of premium wollastonite powder is key to its effectiveness in ceramic formulations. When mixed into tile bodies, these needle-like particles interlock within the ceramic matrix, creating a reinforced structure that significantly improves mechanical strength. This results in tiles with higher impact resistance and flexural strength, reducing breakage during transportation, installation, and daily use—an essential quality for commercial and residential applications alike.

Firing shrinkage is a major challenge in ceramic production, often leading to warping or dimensional inconsistencies. Wollastonite powder mitigates this by reducing the overall shrinkage rate of the tile body during kiln firing. Its low thermal expansion coefficient helps maintain the tile’s shape at high temperatures (typically 1000–1200°C), ensuring uniform dimensions across production batches. This not only reduces waste from defective pieces but also streamlines the manufacturing process by minimizing the need for post-firing adjustments.

In glaze applications, wollastonite powder enhances adhesion between the glaze layer and the ceramic body. Its chemical compatibility with common glaze components (such as feldspar, silica, and oxides) promotes better bonding, preventing glaze cracking or peeling—a common issue in tiles exposed to temperature fluctuations or moisture. Additionally, wollastonite’s high whiteness contributes to brighter, more vibrant glaze colors, allowing manufacturers to achieve consistent aesthetic results without relying on excessive pigmentation.

Industrial-grade wollastonite powder for ceramics undergoes rigorous processing to ensure low impurity levels, particularly iron and titanium, which can cause discoloration. Particle size distribution is also tightly controlled: finer grades (typically 325–1250 mesh) are used for glaze formulations to ensure smooth application, while coarser grades may be incorporated into tile bodies for structural reinforcement. Suppliers often provide technical data on oil absorption and pH levels to help ceramic producers optimize their formulations, ensuring compatibility with existing production lines.

Cost efficiency is another advantage of incorporating wollastonite powder into ceramic tile production. By reducing the need for expensive additives like zirconium silicate (used for whiteness) and lowering firing temperatures through improved thermal conductivity, wollastonite helps manufacturers cut energy and material costs. Its abundance and widespread availability further support its use as a cost-effective alternative to traditional ceramic fillers.