Website: https://www.hezhenshiye.com

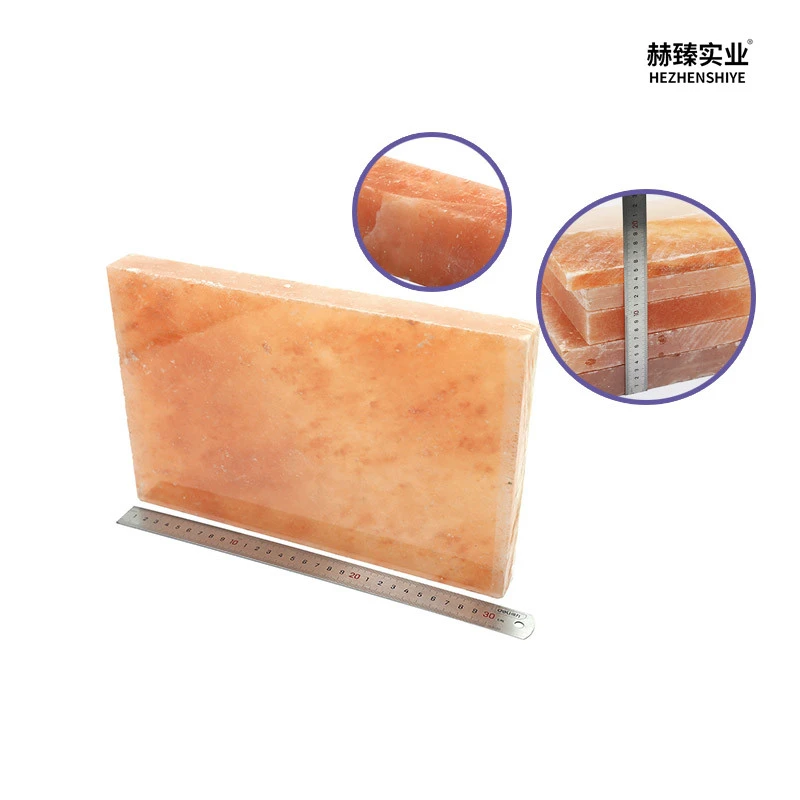

Product Details: Hezhen Kaolin ceramic coating binder filled with clay powder rubber refractory calcined wash kaolin

Phone (Main): 400-613-8488

Mobile: +8615633815566

Email: info@hezhensy.com

Address: No. 8 Xisha East Road, Shikan Village, Ciyu Town, Lingshou County, Shijiazhuang City, Hebei Province

Product Overview: Hezhen Kaolin Ceramic Coating Binder Filled with Clay Powder Rubber Refractory Calcined Wash Kaolin

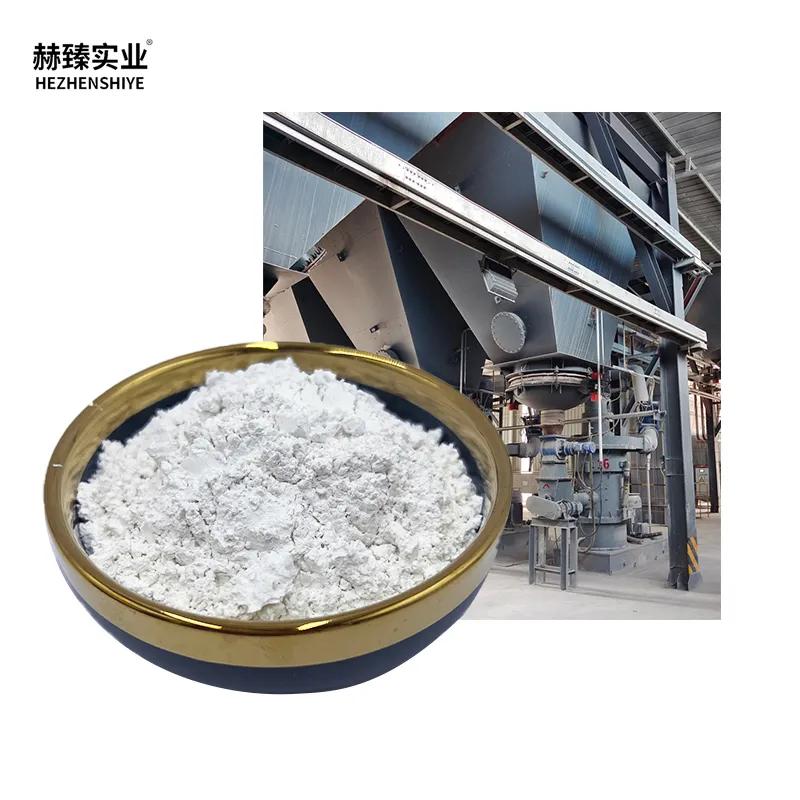

The Hezhen Kaolin ceramic coating binder filled with clay powder rubber refractory calcined wash kaolin is engineered with superior whiteness, optimized particle size, low iron content, high refractoriness, and excellent plasticity. It provides enhanced durability, insulation, and aesthetic finish in every application.

Industry Trends & Market Analysis

Core drivers include:

- Stricter technical standards for thermal insulation and mechanical strength

- Accelerating demand for sustainable, eco-friendly mineral binders

- Rising investments in high-tech ceramics, EV batteries, and flame-retardant rubber products

With its advanced processing and technical innovation, Hebei Hezhen Industry Co.,Ltd. delivers stable, globally-certified Hezhen Kaolin ceramic coating binder filled with clay powder rubber refractory calcined wash kaolin for global markets.

| Parameter | Typical Value | Test Standard | Industry Range | Advantage |

|---|---|---|---|---|

| Whiteness (R457, ISO) | 86%–92% | ISO 2469 | 80%–92% | Excellent Color Brightness |

| Particle Size (D50) | 2–4 μm | ASTM D7928 | 1–7 μm | Smooth Surface Finish |

| Moisture Content | <0.8% | ASTM D2216 | <1.5% | Improved Handling Stability |

| Iron Oxide (Fe2O3) | <0.65% | ISO 1248 | <1.2% | High Purity for Ceramics |

| pH Value (10% Slurry) | 5.8–7.2 | ASTM D1208 | 5.0–8.0 | Neutral - Easy Processing |

| Oil Absorption | 50–59 g/100g | ASTM D281 | 40–65 g/100g | Optimal Filler for Rubber |

| Refractoriness | >1750°C | ISO 1893 | 1650–1800°C | High-Temperature Resilience |

Core Application Scenarios

- Advanced Ceramic Coatings: As a high-purity binder and filler, the Hezhen Kaolin ceramic coating binder filled with clay powder rubber refractory calcined wash kaolin ensures uniform surface morphology, enhanced whiteness, mechanical strength, and improved glaze adhesion in tiles, sanitary ware, and tableware production industries.

- Rubber Compounding: Enables optimized tensile strength, abrasion resistance, and elastic recovery as a cost-effective mineral filler in tire, hose, mat, and sealant compounds.

- High-Temperature Refractories: Essential matrix binder in castables, bricks, crucibles, and kiln linings, the calcined kaolin delivers superior resistance to deformation, thermal cycling, and alkaline atmospheres.

- Paints & Industrial Coatings: As a functional pigment extender, offers improved coverage, hiding power, and rheological stability in water-based/solvent-based coatings.

- Plastics & Polymers: Reduces shrinkage and improves heat distortion resistance as an effective reinforcement mineral in high-performance polymer blends.

- Catalyst Carriers: Acts as a support for zeolites and fluid catalytic cracking (FCC) applications, owing to its unique negative charge and surface area.

Expertise, Authoritativeness & Trustworthiness (EEAT)

- Backed by ISO 9001 and REACH certifications (ISO, ECHA), Hebei Hezhen Industry Co.,Ltd. demonstrates consistent product quality and regulatory compliance, ensuring global trust.

- Referenced in technical papers, such as "Kaolin Applications in Ceramics" (Ceramics International, Elsevier), confirming superior performance of calcined wash kaolin as high-performance ceramic binders/fillers.

- Endorsed by user case studies on kaolin forums and industrial exhibitions (The Kaolin Forum).

- Harmonized with international quality and environmental standards, aligning with advanced process control and sustainable material sourcing, as highlighted in the Journal of Asian Ceramic Societies.

Technical Parameters & Trending Analysis (Visualization)

Professional FAQ: Hezhen Kaolin Ceramic Coating Binder

- 1. What is the main mineral composition of Hezhen Kaolin ceramic coating binder filled with clay powder rubber refractory calcined wash kaolin?

- It primarily consists of high-purity kaolinite (Al₂Si₂O₅(OH)₄), with minor quartz and trace mica, ensuring superior dispersion and low impurity profiles for ceramic and rubber applications.

- 2. What specification standards are used for size and purity control?

- Particle size distribution is measured by D50 (2–4 μm), and purity is guaranteed with Fe₂O₃ below 0.65% (ISO 1248). The product is certified under ISO 9001 for quality management, ensuring tight control over specification variances.

- 3. How does calcination affect kaolin binder properties?

- Calcination at >950°C restructures kaolinite, reducing moisture and increasing mechanical strength, brightness, and thermal stability—essential attributes for refractories and ceramic binders (See ResearchGate).

- 4. What installation standards should be followed for refractory and ceramic applications?

- Follow ASTM C401/C704 for refractory castables and EN 14411 for ceramic tiles. Proper mixing, compaction, and sintering are vital for maximizing the strength and lifecycle of products using Hezhen calcined wash kaolin.

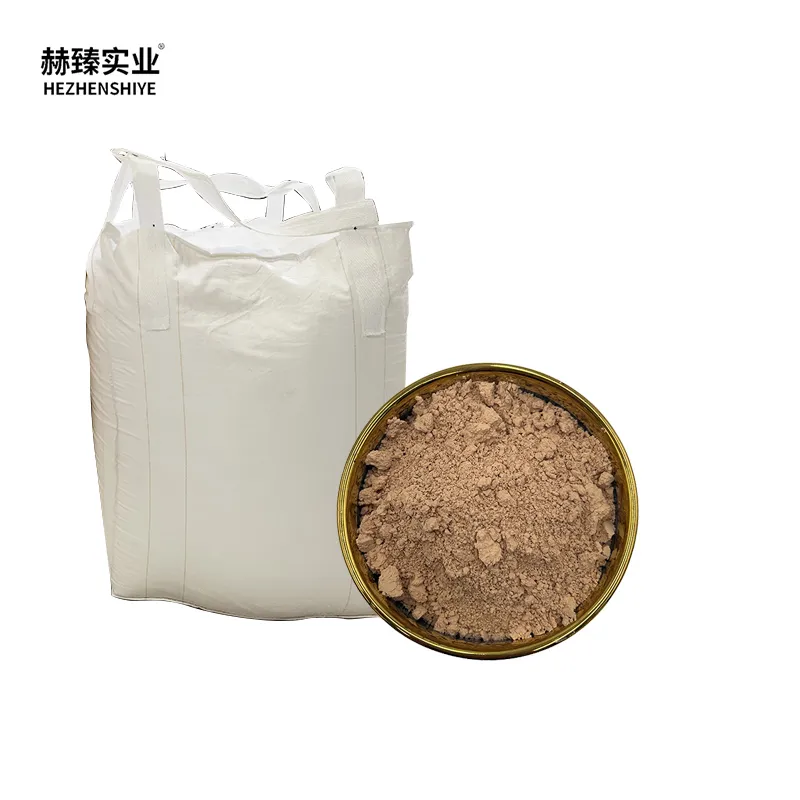

- 5. How is the product packaged and stored?

- Each batch of Hezhen Kaolin ceramic coating binder filled with clay powder rubber refractory calcined wash kaolin is delivered in 25kg or 1000kg jumbo bags, with moisture-proof liners. Storage should be in dry, shaded, and ventilated conditions to ensure optimal performance.

- 6. Can the product be customized for special applications?

- Yes, Hebei Hezhen offers tailorable D50, whiteness, and chemical parameters to suit specific needs in ceramics, advanced polymer compounding, or high-alumina refractory blends — contact us for customized solutions.

- 7. What are the main performance advantages compared to regular raw clays?

- Hezhen calcined kaolin stands out with higher whiteness, lower iron, superior thermal resilience, and unparalleled rheological properties, enabling elevated quality in final products and cost-effective processing.

Conclusion & Further Reading

The Hezhen Kaolin ceramic coating binder filled with clay powder rubber refractory calcined wash kaolin is a pivotal material solution for innovation in the global ceramics, refractories, and polymer/rubber sectors. Its unique blend of high purity, engineered particle size, exceptional whiteness, and certified performance creates safer, more durable, and competitive products.

Whether your focus is advanced ceramics, specialty rubber, or industrial coatings, Hebei Hezhen Industry Co.,Ltd. is committed to providing tailored, high-quality mineral binders. For technical consultation, samples, or custom applications, engage with the experts at Hezhen Kaolin ceramic coating binder filled with clay powder rubber refractory calcined wash kaolin.

[1] "Kaolin Market by Process, Application & Region", MarketsAndMarkets

[2] "Kaolin Applications in Ceramics", Ceramics International

[3] The Kaolin Forum, IMFORMED Industry Bulletin

[4] Y. Wei et al., "Effects of Calcined Kaolin Addition on Physical–Mechanical Properties of Alumina Ceramics", Journal of Asian Ceramic Societies

[5] Regulatory Overview, ECHA / REACH

[6] Product Standards of Kaolin and Clay, ISO International

[7] Properties of Calcined Kaolin, ResearchGate