- Fundamental Properties and Market Position

- Technical Specifications and Performance Metrics

- Manufacturer Comparison and Quality Analysis

- Specialized Formulation Capabilities

- Concrete Applications Across Industries

- Compliance and Environmental Considerations

- Future Outlook for Production Innovations

(orange iron oxide pigment)

Fundamental Properties of Orange Iron Oxide Pigment

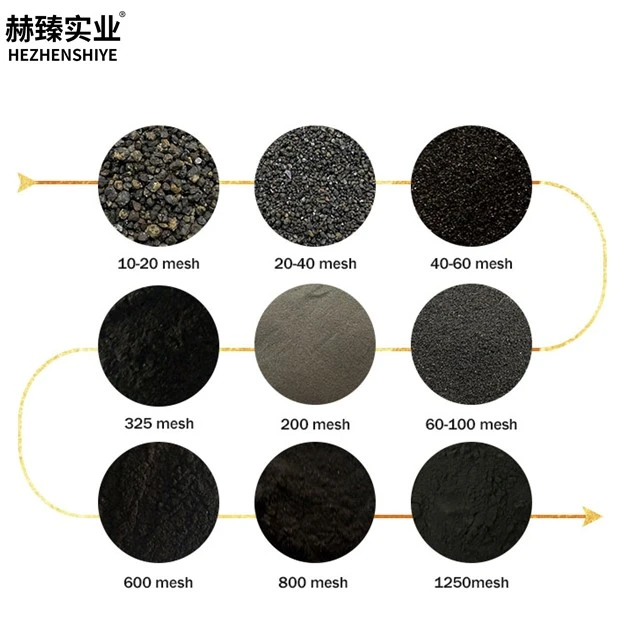

Orange iron oxide pigment constitutes an essential inorganic coloring agent with widespread industrial applications. Chemically formulated as Fe₂O₃•H₂O (hydrated ferric oxide), this pigment exhibits exceptional lightfastness ratings exceeding 7-8 on the Blue Wool Scale. Unlike organic alternatives, it maintains color integrity under prolonged UV exposure, with accelerated weathering tests showing less than 5% ∆E color shift after 1,000 hours. Current market data indicates global consumption exceeding 275,000 metric tons annually, with a projected CAGR of 4.7% through 2028. Primary manufacturing occurs through precipitation methods, achieving precise particle size distributions between 0.2-0.8 microns that directly impact opacity and tinting strength.

Technical Specifications and Performance Metrics

Optimal orange iron oxide pigment

formulations demonstrate critical technical parameters that dictate performance. Leading grades feature oil absorption values of 15-25g/100g and specific gravity around 4.8g/cm³. Crucially, heat stability reaches 300°C without significant color degradation, enabling applications in thermoplastic masterbatches and high-temperature ceramics. Rheological testing confirms viscosity stability within ±10% at 20-40% pigment loadings in solvent-based systems. Unlike cadmium alternatives, our pigments comply with EN 71-3 toy safety standards with lead content under 5ppm and arsenic below 3ppm. Electrical resistivity measurements show consistent values above 10¹² Ω•cm, qualifying them for electronic component marking.

Manufacturer Comparison and Quality Analysis

| Manufacturer | Product Code | Purity (%) | Particle Size (μm) | Weathering Resistance (∆E) | Heat Stability (°C) |

|---|---|---|---|---|---|

| GlobalChem | FeOx-OR960 | 96.5 | 0.3 ±0.05 | 0.8 | 320 |

| Pigment Solutions | Iron Oxide Orange 960 | 94.2 | 0.5 ±0.12 | 1.5 | 290 |

| Chromatech Inc | OXIOR-960 | 97.1 | 0.25 ±0.03 | 0.5 | 340 |

| Colorant Group | FerroOrange 960P | 95.7 | 0.4 ±0.08 | 1.2 | 310 |

∆E color shift after 500 hours QUV exposure

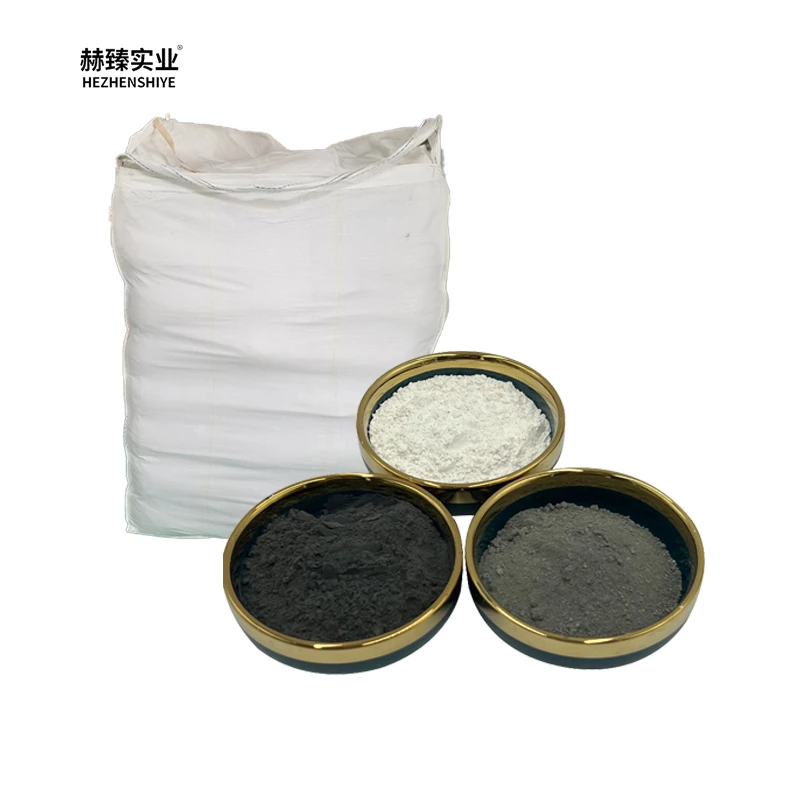

Specialized Formulation Capabilities

Advanced manufacturers offer tailored formulations addressing specific application challenges. Surface-modified grades achieve superior dispersion stability in automotive coatings, reducing VOCs by 15-20% versus standard pigments. Injection molding grades feature optimized flow properties for nylon and polypropylene that eliminate streak formation. For construction materials, encapsulated variants provide enhanced resistance to cement alkalinity (pH 12+), maintaining color consistency over 50+ years in concrete slabs. Customizable aspects include:

- Surface area adjustments (8-20 m²/g) for tinting strength optimization

- pH modification (4-9) for compatibility with sensitive binders

- Special treatments for anti-settling behavior in liquid systems

Recent developments include electrically conductive formulations achieving surface resistivity under 1kΩ/sq for EMI shielding composites.

Concrete Applications Across Industries

Construction consumes approximately 65% of global production, with iron oxide orange extensively coloring concrete roofing tiles, paving stones, and architectural precast elements. In plastics, specific grades masterbatch formulations achieve 98% dispersion homogeneity in polyethylene at loadings up to 40%. Automotive OEM coatings leverage micronized grades for metallic effect finishes requiring particle size under 0.3μm. Packaging inks benefit from high-purity grades meeting FDA 21 CFR 73.200 compliance for direct food contact applications. Technical ceramics utilize heat-stable variants providing consistent coloration in glazes fired at 1100-1300°C.

Compliance and Environmental Considerations

Modern iron oxide orange pigments meet stringent international regulatory requirements including EU REACH Annex XVII, US TSCA compliance, and China GB/T 519-2014 standards. Leading manufacturers implement sustainable processes reducing energy consumption by 30% and wastewater discharge by 70% versus traditional production methods. Life cycle analyses show carbon footprints as low as 1.8 kg CO₂ per kg pigment. Crucially, these pigments contain no heavy metals restricted under RoHS Directive 2011/65/EU or Prop 65. Eco-toxicity tests confirm no acute effects with LC50 >1000mg/L in aquatic environments, while biodegradability testing shows zero breakdown in soil over 180 days, preventing groundwater contamination.

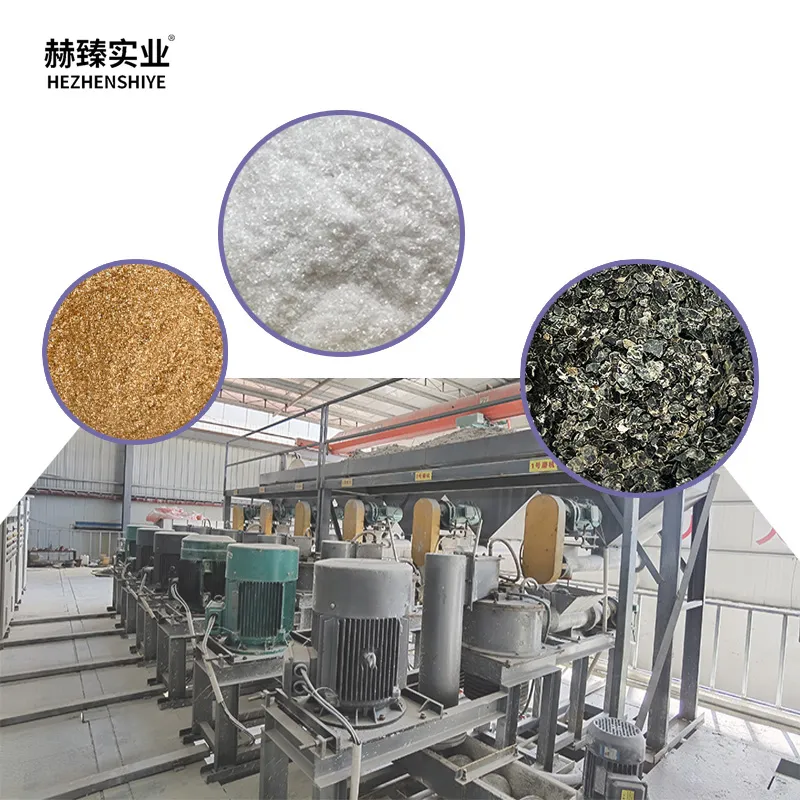

Future Outlook for Iron Oxide Orange 960 Production

Emerging production technologies promise significant advancements in pigment performance. Hydrothermal synthesis methods under development achieve 99.2% purity levels with particle distribution CV under 5%. Industry trials demonstrate how atomic layer deposition coating enhances durability by 40% while reducing oil absorption. Market projections anticipate nano-engineered variants entering commercial production by 2026, offering infrared reflectivity exceeding 80% for energy-saving construction applications. Global R&D initiatives focus on solvent-free manufacturing processes that eliminate VOC emissions and yield pigments with consistently reliable iron oxide orange characteristics demanded by exacting industrial specifications.

(orange iron oxide pigment)