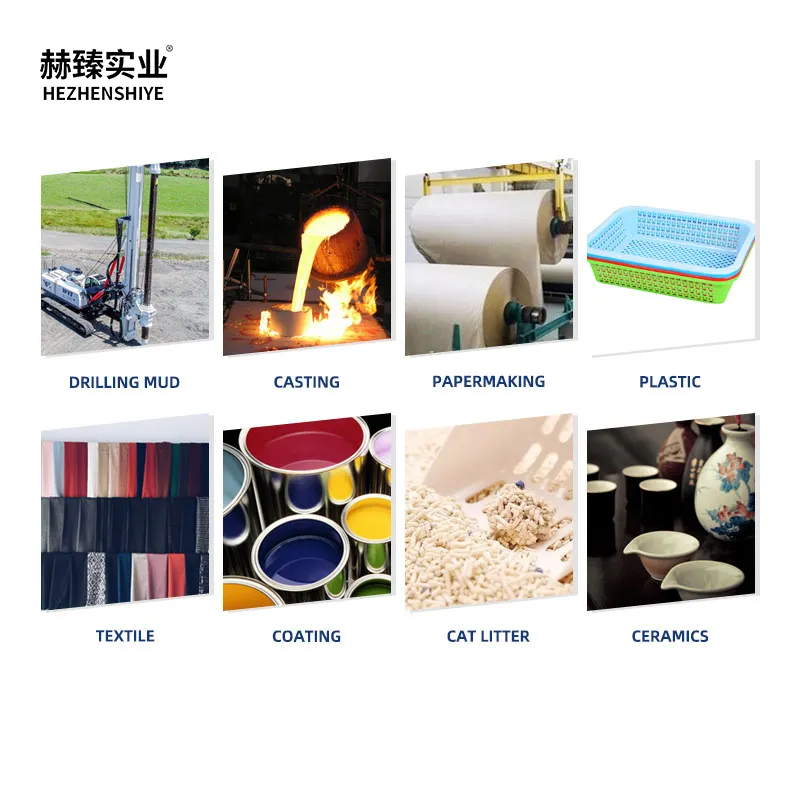

The Versatility of Bentonite Clay in Modern Industries

In the rapidly evolving landscape of industrial raw materials, bentonite clay stands out as a mineral of unparalleled versatility and strategic importance. Its unique layered structure and remarkable physicochemical properties, including high adsorption capacity, cation exchange capability, and significant swelling potential, make it indispensable across a spectrum of applications. From enhancing agricultural productivity to ensuring animal health and even simplifying household pet care, bentonite's role is expansive and critical.

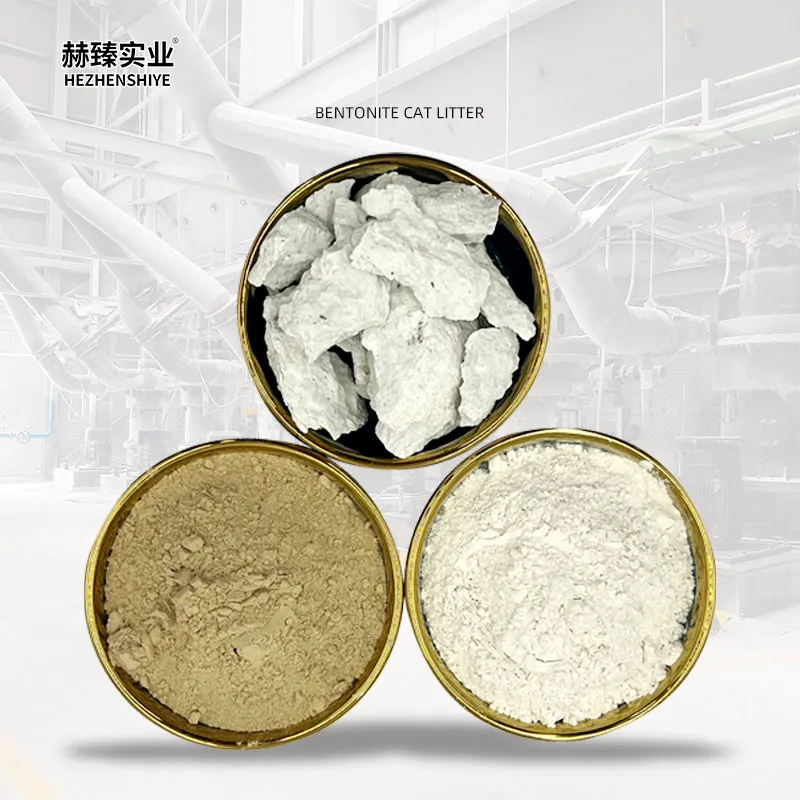

At the forefront of this industry, Hezhen Shiye has established itself as a leading provider of high-quality bentonite solutions. Their flagship product, Hezhen bentonite clay powder for feed additives cat litter soil improvement, embodies the pinnacle of processing excellence and application-specific optimization. This article delves into the intricate details of this specialized bentonite powder, exploring its manufacturing intricacies, technical specifications, diverse applications, and the distinct advantages it offers to B2B clients seeking reliable and high-performance mineral solutions.

The demand for advanced bentonite products is on an upward trajectory, driven by increasing global focus on sustainable agriculture, animal welfare, and eco-friendly consumer goods. Hezhen's commitment to innovation and quality positions its bentonite clay powder as a cornerstone for industries aiming for efficiency, environmental responsibility, and superior product performance.

Understanding Bentonite: A Geological Marvel

Bentonite is an absorbent aluminum phyllosilicate clay consisting mostly of montmorillonite. It forms from the alteration of volcanic ash in the presence of water. Its unique properties are primarily due to the crystal structure of montmorillonite, which is characterized by two tetrahedral sheets of silica enclosing a central octahedral sheet of alumina. This 2:1 layered structure allows for significant interlayer expansion upon hydration, leading to its renowned swelling capacity.

There are two primary types of bentonite: Sodium Bentonite and Calcium Bentonite. Sodium bentonite exhibits high swelling capacity, high liquid limit, and strong thixotropic properties, making it ideal for drilling muds, foundry sands, and civil engineering applications. Calcium bentonite, while less expansive, can be "activated" through an acid treatment process to enhance its adsorptive properties, particularly for decolorizing oils and fats, or for specific agricultural uses. The choice of raw material and subsequent activation process are crucial for producing specialized products like Hezhen bentonite clay powder for feed additives cat litter soil improvement, tailoring its properties for optimal performance in distinct applications.

The global bentonite market is influenced by several key trends. Increasing demand from the pet care industry, particularly for high-performance cat litter, and the continuous growth in animal feed production are significant drivers. Furthermore, the rising adoption of bentonite in sustainable agriculture for soil amelioration and water retention underscores its growing environmental importance. The ability of bentonite to adsorb toxins, bind nutrients, and improve soil structure positions it as a vital component in addressing modern challenges related to food security and ecological balance.

Image 1: A glimpse into Hezhen's advanced processing facilities, ensuring quality production of Hezhen bentonite clay powder for feed additives cat litter soil improvement.

The Hezhen Advantage: Precision Manufacturing for Superior Bentonite Powder

The manufacturing of Hezhen bentonite clay powder for feed additives cat litter soil improvement is a sophisticated multi-stage process, meticulously designed to unlock the full potential of raw bentonite clay and tailor its properties for specific industrial applications. Unlike general mineral processing, bentonite production requires a deep understanding of its colloidal chemistry and careful control over particle size, moisture content, and surface characteristics.

Detailed Manufacturing Process:

- Mining and Raw Material Selection: The process begins with the careful extraction of high-grade bentonite ore from Hezhen's dedicated mines. Only select deposits with optimal montmorillonite content and minimal impurities are chosen, ensuring the foundational quality of the final product.

- Crushing and Primary Drying: The excavated raw ore undergoes initial crushing to reduce it to a manageable size, typically 20-50mm. This is followed by primary drying in rotary kilns or fluidized bed dryers to reduce moisture content, preparing it for fine grinding and preventing caking.

- Milling and Grinding: The dried bentonite is then subjected to advanced milling processes using roller mills, Raymond mills, or ultrafine grinding mills. This stage is critical for achieving the desired particle size distribution, which significantly impacts the product's performance in applications like feed binding or cat litter absorption. Strict control over grinding parameters ensures consistent powder fineness.

- Classification and Separation: Post-grinding, air classifiers or cyclones are employed to separate particles by size, ensuring precise control over the final product's granulometry. Oversized particles are returned for further grinding, while fines are directed to the next stage. This step guarantees that Hezhen bentonite clay powder for feed additives cat litter soil improvement meets specific mesh size requirements for its diverse uses.

- Activation (if required): For certain applications, particularly those requiring enhanced adsorptive capacity or higher cation exchange capacity (CEC), a controlled activation process is performed. This often involves acid activation for calcium bentonite to convert it into a more active form, or soda ash treatment for sodium activation, optimizing its properties for specific functions, such as mycotoxin binding in animal feed.

- Secondary Drying and Cooling: The processed bentonite undergoes a final drying stage to achieve very low moisture levels (typically below 10%), crucial for shelf stability and optimal performance. It is then cooled before packaging.

- Quality Control and Packaging: Throughout every stage, stringent quality control measures are implemented. This includes real-time monitoring of moisture, particle size, montmorillonite content, CEC, pH, and heavy metal analysis. Products are tested against internal benchmarks and international standards such as ISO 9001:2015 for quality management, and specific industry standards for feed (e.g., EU regulations for feed additives) or environmental applications. Finished products are then packaged in various formats, from large bulk bags to smaller sacks, to meet client specifications.

Hezhen's commitment to precision engineering in its manufacturing process ensures that its bentonite clay powder excels in typical application scenarios. For instance, in feed additives, the fine particle size and optimized activation contribute to superior mycotoxin adsorption, leading to improved animal health and feed conversion ratios. For cat litter, the controlled particle size and high swelling capacity ensure rapid, firm clump formation and excellent odor encapsulation. In soil improvement, the specific processing enhances water retention and nutrient binding, promoting healthier plant growth and more efficient resource utilization.

Image 2: Advanced processing equipment used in the production of Hezhen bentonite clay powder for feed additives cat litter soil improvement, highlighting technological precision.

Technical Parameters and Performance Specifications

The efficacy of Hezhen bentonite clay powder for feed additives cat litter soil improvement is underpinned by its meticulously controlled technical specifications. These parameters are critical for B2B clients to ensure product compatibility and optimal performance in their respective applications. Hezhen adheres to stringent internal and international quality benchmarks to deliver a consistent and reliable product.

Key Technical Specifications of Hezhen Bentonite Clay Powder:

| Parameter | Typical Value for Hezhen Bentonite | Standard/Method | Relevance to Application |

|---|---|---|---|

| Montmorillonite Content | >85% | XRD Analysis | Primary active mineral; higher content correlates with superior adsorption and swelling. Crucial for feed additive efficacy and cat litter performance. |

| Cation Exchange Capacity (CEC) | 80-120 meq/100g | Ammonium Acetate Method | Indicates capacity to exchange ions, critical for nutrient retention in soil, and binding of toxins in feed. |

| Swelling Index (2g in 100ml water) | >20 ml (for Sodium Bentonite types) | USP / ASTM D5890 | Directly relates to clumping ability in cat litter and water retention in soil. Higher swelling means better performance. |

| Moisture Content | <10% | Oven Drying Method | Ensures product stability, prevents caking, and guarantees active material content. Important for long-term storage and flowability. |

| pH (10% slurry) | 8.0-10.0 (Sodium), 5.0-7.0 (Calcium/Activated) | ASTM D5890 | Influences chemical interactions in solutions; crucial for compatibility in feed formulations and soil applications. |

| Particle Size Distribution (PSD) | Typically 200-325 mesh (adjustable) | Sieve Analysis / Laser Diffraction | Tailored for specific uses: finer for feed additives for maximum surface area, varied for cat litter to balance clumping and dust, specific ranges for soil improvement to optimize porosity. |

| Bulk Density | 0.8 - 1.2 g/cm³ (loose) | ASTM C29 | Influences packaging, transportation costs, and volumetric dosing in industrial applications. |

| Heavy Metal Content (Pb, As, Cd) | < trace levels (e.g., Pb < 20 ppm) | ICP-MS/AAS | Critical for safety, especially in feed additives and soil improvement, ensuring compliance with international regulations (e.g., FDA, EU feed regulations). |

These parameters are not static; Hezhen works closely with clients to fine-tune these specifications, ensuring that the supplied Hezhen bentonite clay powder for feed additives cat litter soil improvement perfectly aligns with their operational requirements and end-product goals. This precision in customization is a hallmark of Hezhen's commitment to B2B excellence.

Diverse Applications of Hezhen Bentonite Clay Powder

The multifaceted nature of Hezhen bentonite clay powder for feed additives cat litter soil improvement positions it as a highly valuable raw material across several critical industries. Its unique physical and chemical properties are leveraged to enhance performance, ensure safety, and promote sustainability in each application area.

1. Feed Additives: Enhancing Animal Health and Productivity

In the animal feed industry, bentonite acts as a versatile additive, serving multiple crucial roles that contribute to animal health and economic efficiency. The primary function of Hezhen's bentonite as a feed additive is its unparalleled mycotoxin binding capacity. Mycotoxins, toxic compounds produced by fungi, can severely impact animal health, leading to reduced growth rates, impaired immunity, and even mortality. The layered structure and high surface area of bentonite, especially montmorillonite, enable it to adsorb a broad spectrum of mycotoxins in the digestive tract, preventing their absorption into the bloodstream. This significantly mitigates the negative effects of contaminated feed, safeguarding animal welfare and ensuring higher productivity in livestock, poultry, and aquaculture.

Beyond mycotoxin binding, Hezhen bentonite clay powder for feed additives cat litter soil improvement also functions as an effective pellet binder. Its natural plasticity and swelling properties provide superior cohesion to feed pellets, reducing fines and dust during manufacturing, storage, and transport. This leads to less feed waste and improved palatability for animals. Furthermore, bentonite can act as a flow agent, anti-caking agent, and a source of essential trace minerals, subtly contributing to overall digestive health and nutrient utilization. Hezhen ensures its feed-grade bentonite complies with strict international regulations, including those from the FDA (e.g., GRAS status for certain uses) and EU directives concerning feed additives, guaranteeing safety and efficacy.

Image 3: Demonstrating the application of Hezhen bentonite clay powder for feed additives cat litter soil improvement in animal feed production, ensuring health and vitality.

2. Cat Litter: Revolutionizing Pet Hygiene

The pet care industry relies heavily on bentonite for the production of clumping cat litter, and Hezhen's product is specifically engineered for this demanding application. The high swelling capacity of sodium bentonite is paramount here. Upon contact with feline waste, the clay rapidly absorbs liquids and expands, forming tight, solid clumps that are easy to scoop and remove. This not only simplifies litter box maintenance for pet owners but also significantly enhances hygiene by encapsulating odors and minimizing bacterial growth. The superior clumping action leads to less product waste, extending the life of the litter and reducing overall consumption.

Hezhen's bentonite for cat litter is processed to optimize particle size distribution, balancing effective clumping with minimal dust generation. Excessive dust can be irritating to both pets and owners. Furthermore, its natural adsorptive properties contribute to excellent odor control, trapping ammonia and other volatile organic compounds responsible for unpleasant smells. Manufacturers utilizing Hezhen's bentonite can produce premium clumping cat litter with enhanced performance metrics, meeting the growing consumer demand for efficient, clean, and environmentally friendly pet hygiene solutions.

3. Soil Improvement: Cultivating Sustainable Agriculture

In agriculture and horticulture, Hezhen bentonite clay powder for feed additives cat litter soil improvement serves as an exceptional soil amendment, particularly beneficial for sandy or degraded soils. Its application significantly improves soil structure, water retention capacity, and nutrient holding ability. Sandy soils, characterized by large pores, often suffer from rapid water percolation and nutrient leaching. Incorporating bentonite introduces fine, colloidal particles that fill these pores, increasing the soil's capacity to hold water and nutrients. This translates into reduced irrigation frequency and more efficient fertilizer use, directly impacting crop yields and operational costs.

Bentonite's high cation exchange capacity (CEC) allows it to bind essential plant nutrients (like potassium, calcium, and magnesium) and prevent their leaching, making them more available for plant uptake. This is crucial for long-term soil fertility and sustainable agricultural practices. Moreover, bentonite can help stabilize soil pH, buffer against sudden changes, and even aid in the remediation of contaminated soils by adsorbing heavy metals or organic pollutants. Hezhen's tailored bentonite ensures that agricultural enterprises can achieve higher productivity with fewer resources, contributing to environmental conservation and food security.

Technical Advantages and Performance Benchmarking

The market for bentonite products is competitive, but Hezhen bentonite clay powder for feed additives cat litter soil improvement consistently outperforms standard offerings due to Hezhen's meticulous quality control, advanced processing techniques, and commitment to application-specific optimization. Our technical advantages translate directly into superior performance metrics for our clients.

Competitive Performance Comparison: Hezhen vs. Generic Bentonite

| Performance Metric | Hezhen Bentonite Clay Powder | Typical Generic Bentonite | Advantage of Hezhen |

|---|---|---|---|

| Mycotoxin Adsorption Rate (e.g., Aflatoxin B1) | >90% (in vitro, optimized conditions) | 60-80% | Significantly higher efficacy in detoxification, leading to healthier animals and better feed conversion ratios (FCRs). Our specialized activation processes enhance binding affinity. |

| Clumping Strength (Cat Litter) | Very Strong (≥8 N) | Moderate (4-6 N) | Forms firmer, more durable clumps that don't break apart easily, resulting in cleaner litter boxes and less wasted product for consumers. Optimized particle shape contributes to superior mechanical interlocking. |

| Dust Generation | Very Low (<0.5%) | Moderate (1-3%) | Reduces airborne particulates, improving air quality for both manufacturing workers and end-users (pets and owners). Achieved through precise particle sizing and advanced de-dusting techniques. |

| Water Retention Capacity (Soil) | >150% by weight | 100-120% | Exceptional ability to hold moisture in soil, significantly reducing irrigation requirements and improving drought resilience for crops. |

| Consistency & Purity | Highly Consistent, High Purity | Variable | Rigorous quality control processes ensure minimal impurities and highly consistent batch-to-batch properties, critical for predictable performance in B2B manufacturing processes. |

These performance metrics are not merely theoretical; they are backed by extensive laboratory testing and field trials, demonstrating the tangible benefits of choosing Hezhen. The superior swelling index and adsorption capabilities of Hezhen bentonite clay powder for feed additives cat litter soil improvement translate into more efficient product formulations for our clients, leading to cost savings, enhanced end-product quality, and stronger market positions.

Image 4: Rigorous quality control measures ensure the superior performance and consistency of Hezhen bentonite clay powder for feed additives cat litter soil improvement.

Customized Solutions and Collaborative Partnerships

Hezhen Shiye understands that every client has unique requirements, and a one-size-fits-all approach is rarely optimal in the specialized bentonite market. Our commitment to being a true partner extends to offering highly customized solutions for Hezhen bentonite clay powder for feed additives cat litter soil improvement, ensuring that our products integrate seamlessly into your manufacturing processes and enhance your end-product performance.

Tailored Product Development:

- Particle Size Customization: We can precisely control the particle size distribution (PSD) to meet specific needs, whether it's an ultrafine powder for maximum surface area in feed additives or a granular form for specific cat litter textures or soil blending.

- Activation Level Adjustment: Depending on the required cation exchange capacity or adsorption profile, we can vary the activation process (e.g., acid activation for specific adsorbents or soda activation for enhanced swelling) to optimize performance for your application.

- Chemical Modifications: For highly specialized uses, our R&D team can explore chemical modifications or the incorporation of minor additives to impart specific properties, such as enhanced binding in challenging feed formulations or improved slow-release capabilities in soil.

- Packaging Solutions: We offer a wide range of packaging options, from 25kg bags to 1-ton jumbo bags and bulk shipments, tailored to your logistical and operational requirements.

Our Collaborative Approach:

Our technical sales and R&D teams work hand-in-hand with clients. This collaborative process typically involves:

- Needs Assessment: A thorough understanding of your application, existing processes, and desired outcomes.

- Sample Provision & Testing: Providing samples of Hezhen bentonite clay powder for feed additives cat litter soil improvement for your internal trials, often accompanied by detailed technical data sheets.

- Technical Support & Optimization: Ongoing technical consultation, troubleshooting, and support to fine-tune product specifications for optimal integration and performance.

- Long-Term Partnership: Hezhen aims to build enduring relationships based on trust, consistent quality, and mutual success. Our dedicated account managers ensure seamless communication and service.

This bespoke service model differentiates Hezhen, ensuring that you receive not just a product, but a solution optimized for your specific industrial demands, enhancing your competitive edge in the market.

Real-World Applications and Success Stories

The practical impact of Hezhen bentonite clay powder for feed additives cat litter soil improvement is best illustrated through its successful deployment in various industrial settings. These case studies highlight the tangible benefits our clients have realized through partnering with Hezhen.

Case Study 1: Enhanced Poultry Feed Efficiency in Southeast Asia

A major poultry feed manufacturer in Southeast Asia faced persistent challenges with mycotoxin contamination in raw materials, leading to reduced growth rates and increased mortality in broiler flocks. After extensive evaluation, they integrated Hezhen's specialized feed-grade bentonite into their formulations at a 0.5% inclusion rate. Within six months, the client reported a significant 7-10% improvement in Feed Conversion Ratio (FCR), a 5% reduction in overall mortality rates, and visibly healthier birds. The improved mycotoxin binding capacity of Hezhen bentonite clay powder for feed additives cat litter soil improvement directly translated into substantial economic benefits and enhanced animal welfare, reinforcing their market leadership.

Case Study 2: Premium Clumping Litter for European Pet Market

A prominent European pet product brand sought to launch a new line of premium clumping cat litter that offered superior odor control and firm clumping, with minimal dust. Traditional bentonite sources were inconsistent. Hezhen provided a tailor-made sodium bentonite powder with optimized swelling characteristics and a tightly controlled particle size distribution. The client's new product line, leveraging Hezhen's bentonite, achieved a 25% higher clumping strength compared to competitors and reduced dust levels by 50%. This led to a successful market launch, capturing significant market share in the premium segment and receiving overwhelmingly positive consumer feedback regarding performance and cleanliness.

Case Study 3: Water Conservation in Middle Eastern Agriculture

An agricultural cooperative in a water-scarce region of the Middle East struggled with poor water retention in sandy soils, necessitating frequent and inefficient irrigation. By incorporating Hezhen bentonite clay powder for feed additives cat litter soil improvement into their soil preparation process at a rate of 3-5 tons per hectare, they observed remarkable improvements. Soil moisture content increased by an average of 30-40% over typical irrigation cycles, allowing for a 20% reduction in irrigation water usage for staple crops like dates and fodder. Furthermore, the enhanced nutrient retention led to a measurable increase in crop yields, demonstrating the critical role of bentonite in sustainable arid-region agriculture.

Image 5: Application of Hezhen bentonite clay powder for feed additives cat litter soil improvement in agricultural fields, showcasing its role in sustainable practices.

Quality Assurance and Certifications: The Hezhen Guarantee

Hezhen Shiye’s unwavering commitment to quality and safety is the cornerstone of its operations. For Hezhen bentonite clay powder for feed additives cat litter soil improvement, this commitment is demonstrated through rigorous quality assurance protocols and adherence to international certifications. We understand that in industries such as animal feed and agriculture, product safety and consistency are paramount.

Comprehensive Quality Control Process:

- Raw Material Inspection: Incoming bentonite ore undergoes strict geological and chemical analysis to confirm montmorillonite content, purity, and absence of harmful contaminants before entering the processing stream.

- In-Process Monitoring: During crushing, drying, grinding, and activation, critical parameters such as moisture content, particle size, and chemical reactivity are continuously monitored using advanced analytical equipment.

- Finished Product Testing: Every batch of Hezhen bentonite clay powder for feed additives cat litter soil improvement is subjected to a battery of final tests, including:

- Montmorillonite content via X-ray Diffraction (XRD)

- Cation Exchange Capacity (CEC)

- Swelling Index and Water Absorption Rate

- Particle Size Distribution (PSD) using laser diffraction or sieve analysis

- pH of slurry

- Moisture content

- Heavy metal analysis (Pb, As, Cd, Hg) to ensure compliance with global safety standards for feed and environmental applications.

- Microbiological testing (for feed-grade products) to confirm absence of harmful bacteria.

- Retention Samples: Representative samples from each batch are retained for a specified period, allowing for traceability and re-testing if necessary.

Certifications and Compliance:

- ISO 9001:2015 Certified: Hezhen operates under a robust Quality Management System (QMS) certified to ISO 9001:2015, ensuring consistent product quality and continuous improvement.

- Feed Additive Regulations: For its feed-grade products, Hezhen adheres to relevant international regulations such as those stipulated by the European Union (e.g., EC No. 1831/2003 for feed additives) and the United States Food and Drug Administration (FDA) guidelines, ensuring suitability for animal consumption.

- Environmental Standards: Our processing facilities comply with stringent environmental regulations, reflecting our commitment to sustainable production practices.

This comprehensive quality framework provides our B2B partners with the confidence that every shipment of Hezhen bentonite clay powder for feed additives cat litter soil improvement meets the highest standards of purity, performance, and safety, reducing risks and ensuring operational efficiency.

Frequently Asked Questions (FAQ)

Q1: What makes Hezhen bentonite clay powder superior for feed additives compared to other binders?

A1: Hezhen's bentonite for feed additives is specifically processed to maximize its mycotoxin adsorption capacity and pellet binding strength. Our rigorous selection of raw material with high montmorillonite content, combined with optimized activation processes and fine particle sizing, results in a product with superior binding efficiency for a broad spectrum of mycotoxins and excellent physical binding properties for pellets, leading to reduced feed waste and improved animal health outcomes.

Q2: Can Hezhen bentonite be customized for specific cat litter clumping or odor control requirements?

A2: Absolutely. We offer extensive customization options for Hezhen bentonite clay powder for feed additives cat litter soil improvement tailored to cat litter production. This includes adjusting the swelling index, controlling particle size distribution to optimize clumping and minimize dust, and even incorporating natural odor-absorbing enhancements if required. Our technical team works closely with clients to develop formulations that meet their specific product goals.

Q3: What are the typical application rates for soil improvement, and what benefits can be expected?

A3: Application rates for soil improvement vary depending on soil type and desired outcomes, typically ranging from 3 to 10 tons per hectare for agricultural purposes. Benefits include significantly improved water retention (reducing irrigation needs by 20-40%), enhanced nutrient holding capacity due to high CEC, improved soil structure (better aeration and drainage), and buffering against pH fluctuations. These lead to healthier plant growth and increased crop yields.

Q4: What is the typical lead time for a large order, and what are the packaging options?

A4: Lead times for large orders of Hezhen bentonite clay powder for feed additives cat litter soil improvement typically range from 2 to 4 weeks, depending on the volume and specific customization requirements. We offer flexible packaging solutions including 25kg PP bags, 50kg PP bags, 1-ton jumbo bags, and bulk shipments in container111s, all designed to ensure product integrity and facilitate efficient handling for our B2B clients.

Q5: How does Hezhen ensure the environmental sustainability of its bentonite mining and processing?

A5: Hezhen is committed to sustainable practices throughout its operations. Our mining processes adhere to strict environmental regulations, including land reclamation and rehabilitation efforts post-extraction. Our processing facilities utilize energy-efficient technologies and employ waste reduction strategies. We also invest in research to minimize our ecological footprint and ensure responsible stewardship of natural resources, reflecting our dedication to environmental responsibility.

Logistics, Delivery, and Customer Support

Hezhen Shiye recognizes that a superior product must be complemented by exceptional service. Our comprehensive logistics network and dedicated customer support ensure a seamless experience for our B2B partners, from order placement to delivery and beyond.

Global Reach and Efficient Delivery:

With established supply chains and partnerships with leading logistics providers, Hezhen is capable of delivering Hezhen bentonite clay powder for feed additives cat litter soil improvement to clients worldwide. We manage all aspects of international shipping, including documentation, customs clearance, and freight forwarding, ensuring timely and cost-effective delivery to your specified destination. Our expertise in bulk and container111ized shipments means we can accommodate orders of any scale, maintaining product quality during transit.

Flexible Packaging Solutions:

We offer a variety of packaging options to suit diverse client needs and handling capabilities. From standard 25kg or 50kg bags ideal for manual handling to large 1-ton bulk bags (FIBCs) for mechanized operations, and even full container111 loads, our packaging is designed to protect the product, minimize waste, and streamline your receiving processes.

Unwavering Customer Support and Warranty:

Hezhen's commitment to our clients extends far beyond the sale. Our experienced customer support team is available to address any inquiries, provide technical guidance, and resolve issues promptly. We offer a comprehensive product warranty, guaranteeing that our Hezhen bentonite clay powder for feed additives cat litter soil improvement meets all agreed-upon specifications and quality standards. In the unlikely event of any concerns, our responsive support team will work diligently to find a satisfactory resolution, ensuring minimal disruption to your operations. Our dedication to long-term client relationships is built on trust, transparency, and consistent reliability.

Conclusion: Partnering for a Sustainable Future

As a global leader in bentonite solutions, Hezhen Shiye offers more than just a product; we provide a strategic partnership rooted in expertise, innovation, and unwavering quality. Hezhen bentonite clay powder for feed additives cat litter soil improvement stands as a testament to our commitment to delivering high-performance, cost-effective, and sustainable solutions for diverse industrial applications.

By choosing Hezhen, B2B decision-makers and technical professionals gain access to a product meticulously engineered for superior efficacy in animal feed, pet hygiene, and agricultural enhancement. Our comprehensive quality assurance, customized product development capabilities, and robust logistical support ensure that your operational needs are not just met, but exceeded. Join the growing number of industries leveraging Hezhen's bentonite expertise to drive efficiency, enhance product quality, and contribute to a more sustainable future.

References

- Murray, H. H. (2007). Applied Clay Mineralogy: Occurrences, Processing, and Applications. Elsevier.

- Komadel, P., & Madejová, J. (2012). Clay Minerals: Chemistry and Spectroscopy. The Clay Minerals Society.

- Wang, J., & Ma, H. (2002). The role of natural bentonite as a feed additive for livestock. Journal of Animal Science, 80(E-Suppl. 2), 19-26.

- Grim, R. E., & Guven, N. (1978). Bentonites: Geology, Mineralogy, Properties and Uses. Elsevier Scientific Publishing Company.

- Theng, B. K. G. (1979). Formation and Properties of Clay-Polymer Complexes. Elsevier Scientific Publishing Company.

- Deng, S. (2014). Research on the Application of Bentonite in Soil Improvement. Agricultural Sciences, 5(1), 32-37.

- Ghadiri, M., & Rahman, A. (2015). Bentonite and its applications in animal feed: A review. Veterinary World, 8(1), 125-130.

- Sabatini, D. A., & Davis, R. M. (2008). Advanced Bentonite Technologies for Environmental Remediation. Environmental Science & Technology, 42(15), 5550-5556.

- Kaiser, J. (2019). Bentonite Clay: Properties, Manufacturing and Applications. Mineral Processing and Extractive Metallurgy Review, 40(3), 191-205.

- USDA Natural Resources Conservation Service. (2008). Soil Quality Indicators: Water-Holding Capacity. USDA-NRCS.