Descrizione del prodotto

One of the key advantages of this technology is its versatility. The painted surfaces can be applied in various settings, from large - scale water treatment facilities to smaller, household - based systems. For instance, water storage tanks or pipes can be coated with this special paint, continuously purifying the water as it passes through or is stored.

In addition to its purification capabilities, the paint is also durable and long - lasting. It can withstand the harsh conditions often associated with water treatment environments, ensuring consistent performance over time.

This innovation not only offers an environmentally friendly alternative to traditional water purification methods but also has the potential to make clean water more accessible in remote or resource - constrained areas. As research and development in this field continue, we can expect even more exciting applications of white tourmaline - enhanced paint in the future of water purification.

| Cas No. |

14807-96-6 |

| Luogo di origine |

Cina |

| Colore |

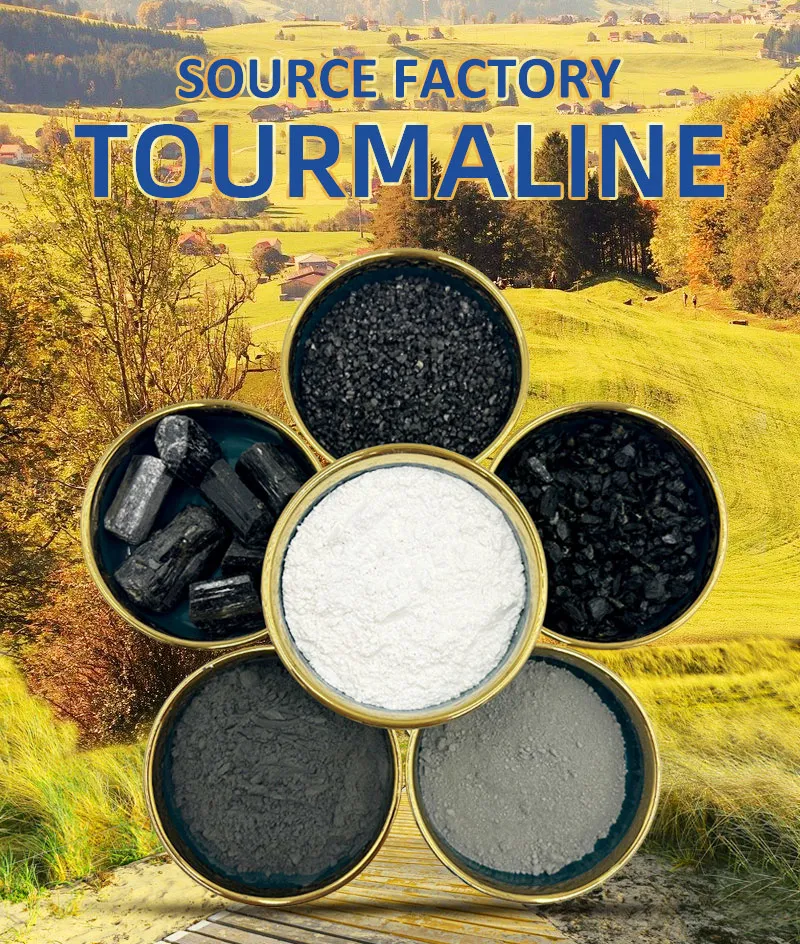

White/Gray |

| Forma |

Powder |

| Purity |

90-95% |

| Grado |

industrial Grade Food Grade |

| Pacchetto |

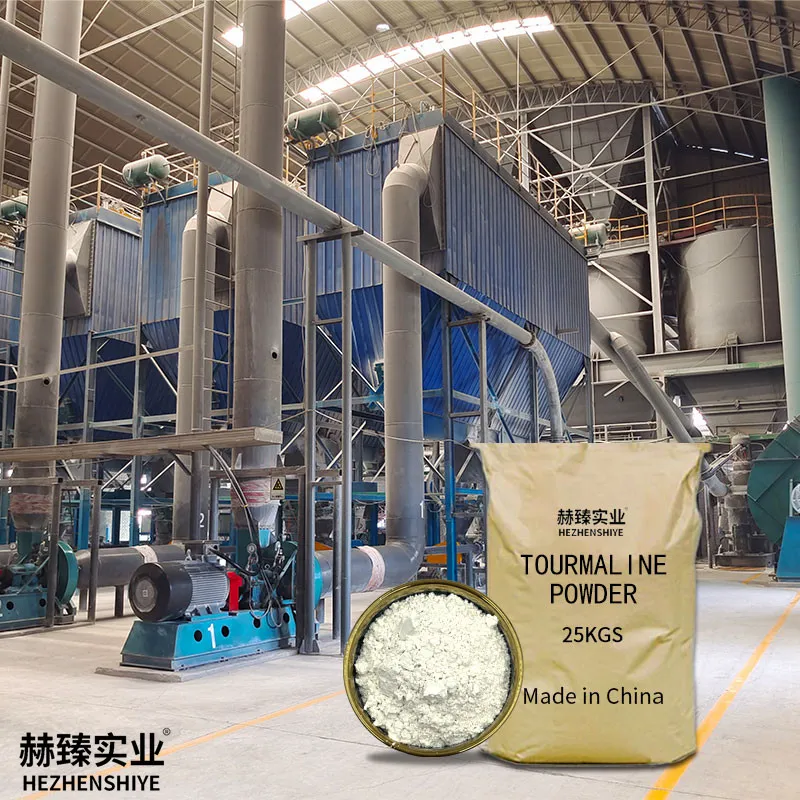

25kg/bag,customized package |

| Quantità minima d'ordine |

1 kg |

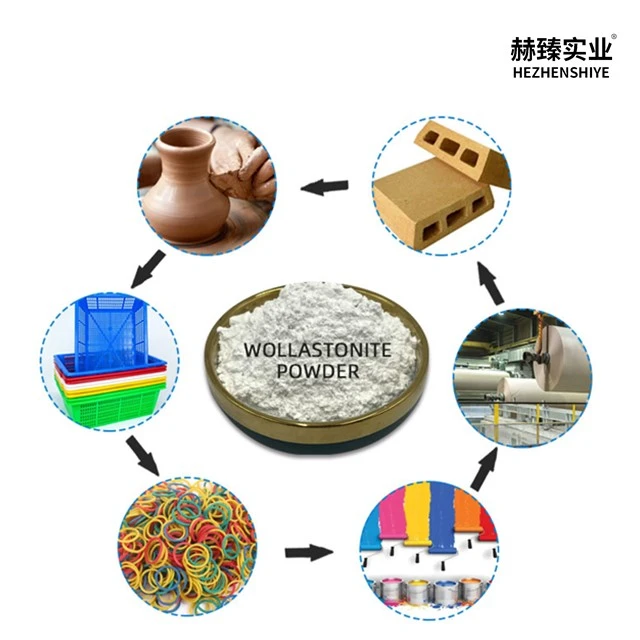

Industrial coatings play a vital role in protecting substrates (such as plastic, metal, and concrete) from corrosion, wear, and environmental damage, while also providing functional properties like antistatic protection. However, traditional coatings face challenges: antistatic additives (e.g., carbon black) often reduce coating whiteness and gloss, while weather-resistant formulations rely on expensive synthetic polymers that increase production costs. Tourmaline powder, with its dual functionality of antistatic performance and weather resistance, has become a game-changing additive for industrial coatings, resolving these issues and enhancing overall coating quality.

The antistatic mechanism of tourmaline powder in coatings is rooted in its unique electrical properties. Unlike conductive additives that require high loading (5-10% by weight) to form a conductive network, tourmaline exhibits permanent piezoelectricity and pyroelectricity—meaning it generates a weak but continuous electrostatic field even without external voltage. This field facilitates the dissipation of static charges on the coating surface, preventing charge accumulation that can attract dust, cause electrostatic discharge (ESD), or damage sensitive electronic components. When added at just 2-5% by weight, tourmaline powder reduces the surface resistance of coatings from 10¹²-10¹⁴ Ω (static-prone) to 10⁸-10¹⁰ Ω (antistatic range), meeting international standards for ESD protection (e.g., IEC 61340). Importantly, this low loading preserves the coating’s color and gloss—unlike carbon black, which darkens light-colored coatings and reduces gloss by 20-30% at similar addition levels.

Weather resistance is another key benefit of tourmaline powder in industrial coatings. The mineral’s crystalline structure is highly stable under UV radiation, with no significant degradation even after 1000 hours of accelerated weathering testing (per ASTM G154). When incorporated into coatings, tourmaline particles act as UV absorbers, scattering and reflecting UV rays to prevent polymer chain breakage in the coating binder. This reduces chalking, fading, and cracking—common issues with traditional coatings exposed to sunlight and humidity. For example, acrylic coatings containing 3% tourmaline powder retain 90% of their initial gloss after 2000 hours of outdoor exposure, compared to 65% for unfilled acrylic coatings. Additionally, tourmaline’s hydrophobic surface reduces water absorption, preventing blistering and adhesion loss on metal substrates in rainy or humid environments.

Coating durability is further enhanced by tourmaline powder’s reinforcing effect. The powder’s irregular particle shape improves adhesion to both the substrate and the coating matrix, creating a stronger bond that resists peeling and abrasion. Taber abrasion tests (ASTM D4060) show that polyurethane coatings with 4% tourmaline powder have a wear index of 15 mg/1000 cycles, compared to 28 mg/1000 cycles for unfilled coatings—representing a 46% improvement in abrasion resistance. This makes the coatings suitable for high-wear applications, such as metal machinery parts, plastic casings for electronic devices, and concrete floors in industrial facilities.

Compatibility with different coating systems is a major advantage of tourmaline powder. It integrates seamlessly with water-based, solvent-based, and UV-curable coatings, as well as common binders like acrylics, polyurethanes, and epoxies. Unlike some functional additives that react with coating components, tourmaline is chemically inert, ensuring formulation stability and consistent performance. For water-based coatings, the powder can be pre-dispersed in aqueous solutions using a high-shear mixer, achieving uniform particle distribution without sedimentation. For solvent-based systems, it is easily wetted by organic solvents, eliminating the need for additional dispersants.

Customization options cater to diverse industrial coating needs. Suppliers offer tourmaline powder with different particle sizes: fine grades (1-5 μm) for clear or thin coatings (e.g., electronic device casings) to avoid visible particles, and coarser grades (10-20 μm) for thick coatings (e.g., industrial flooring) to maximize abrasion resistance. Surface-treated grades—coated with silane coupling agents—improve compatibility with hydrophobic binders like polyurethanes, further enhancing dispersion and bonding. High-purity grades (95%+ tourmaline content) are ideal for coatings requiring strict color consistency (e.g., automotive parts), while cost-effective grades (80-90% content) suit general industrial use.

Practical application cases highlight tourmaline powder’s impact. A German electronics manufacturer used a tourmaline-enhanced acrylic coating for plastic smartphone casings, achieving antistatic performance (surface resistance 10⁹ Ω) while maintaining the casing’s glossy white finish—something carbon black additives could not achieve. A Chinese automotive parts supplier incorporated 3% tourmaline powder into its epoxy coating for metal engine components, reducing UV-induced fading by 50% and extending the coating’s service life from 2 years to 4 years. These cases demonstrate how tourmaline powder solves specific coating challenges, making it a preferred additive for global manufacturers.

For foreign trade merchants,marketing tourmaline powder as a coating additive requires emphasizing its technical advantages and compliance with international standards. Providing test data on antistatic performance, weather resistance, and abrasion resistance—certified by labs like TÜV or ASTM International—builds credibility. Highlighting cost savings, such as reduced additive loading (2-5% vs. 5-10% for carbon black) and longer coating service life, appeals to cost-conscious clients. Additionally, offering sample kits (with different particle sizes and surface treatments) allows clients to test compatibility with their existing coating formulations, reducing purchase risk.

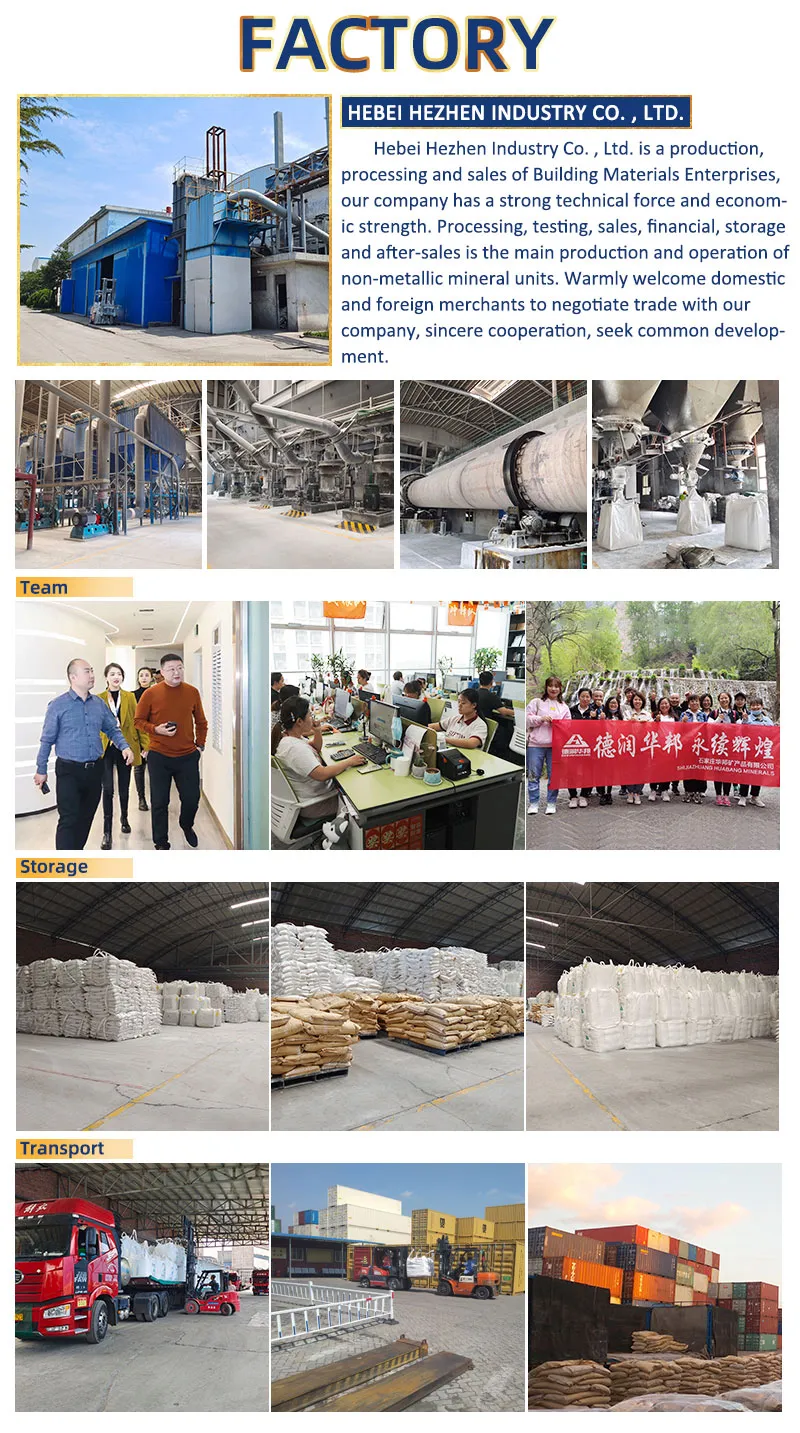

Packaging and logistics support are also critical for international sales. Tourmaline powder should be packaged in moisture-proof, sealed containers to prevent clumping during shipping—25kg kraft paper bags with inner PE liners are standard for small orders, while 1-ton super sacks suit bulk purchases. Providing detailed technical data sheets (TDS) and safety data sheets (SDS) in English ensures compliance with import regulations in target markets (e.g., the EU’s CLP Regulation). Offering flexible lead times (2-4 weeks for standard grades, 4-6 weeks for custom grades) accommodates urgent client needs, a key factor in the competitive coating additive market.

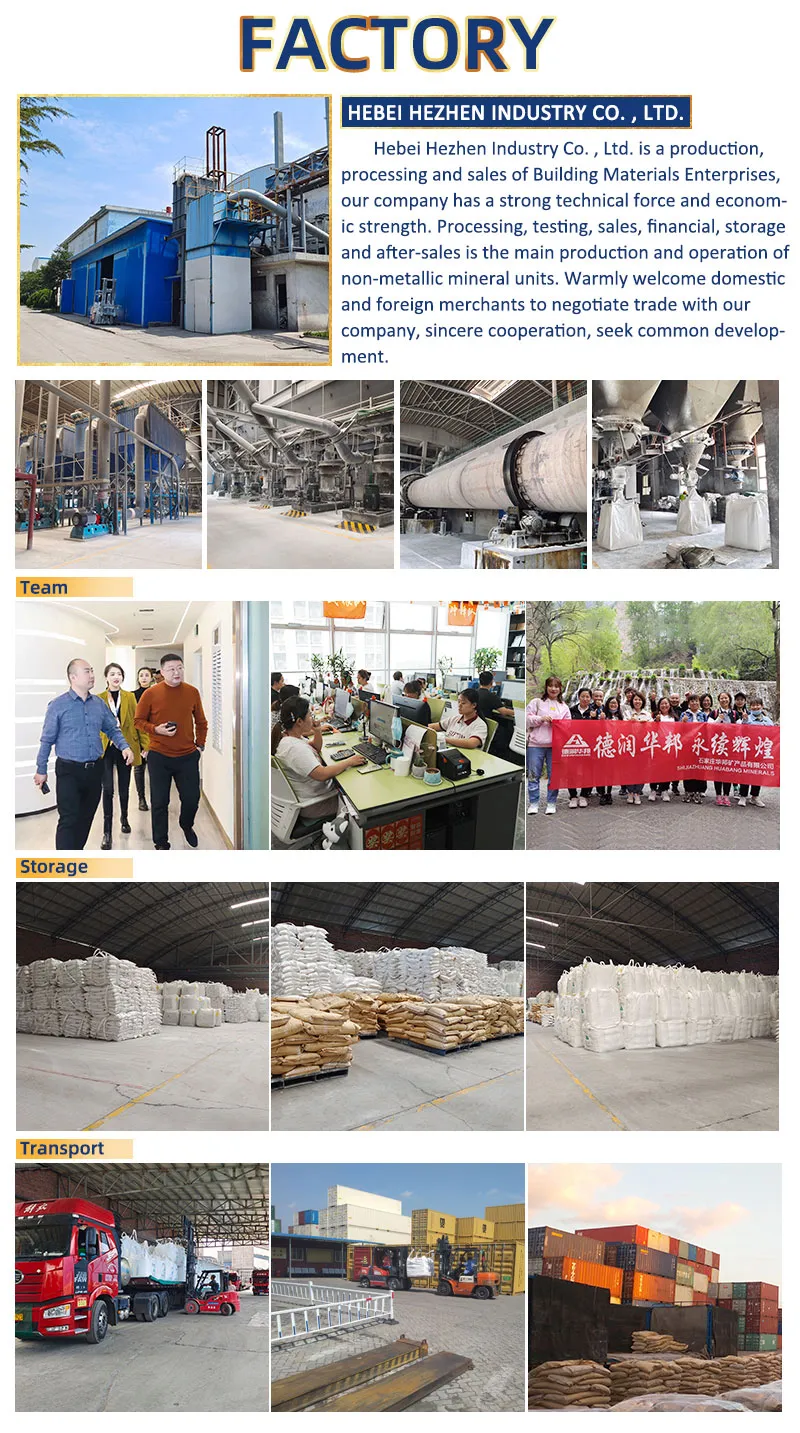

Banner PDF

Banner PDF Richiedi un preventivo

Richiedi un preventivo