Below is a comprehensive overview discussing granular bentonite clay

applications and industrial solutions:

- Fundamental Properties of Granular Bentonite Clay

- Technical Advantages Over Competing Materials

- Manufacturer Comparison: Performance Metrics

- Industry-Specific Customization Options

- Field Application Case Studies

- Handling and Operational Considerations

- Sustainable Development Applications

(granular bentonite clay)

Understanding Granular Bentonite Clay Fundamentals

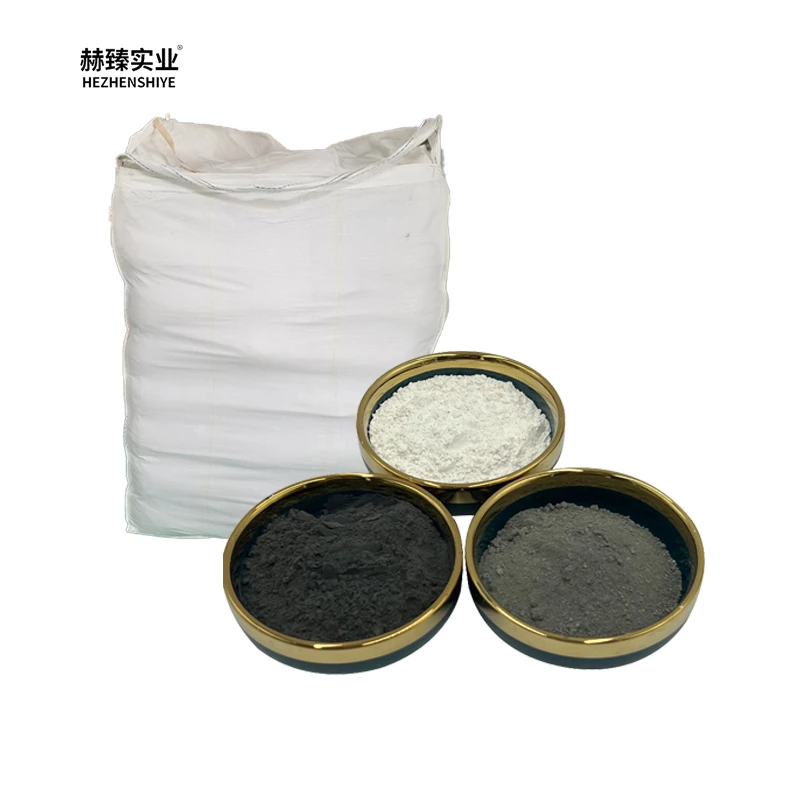

Granular bentonite clay represents a naturally occurring aluminum phyllosilicate with unique molecular expansion capabilities. When hydrated, premium-grade sodium bentonite can swell up to 16 times its original volume, creating impermeable barriers that block fluid migration. This swelling characteristic is quantified by the free swell index (FSI), with industrial-grade granular bentonite exhibiting FSIs between 22-28 ml/2g. Particle size distribution typically ranges from 0.5mm to 5mm, optimized for controlled hydration rates in engineered applications.

Montmorillonite constitutes 70-85% of high-grade deposits, with calcium and sodium variants displaying distinct absorption capacities. Sodium bentonite demonstrates superior cation exchange capacity (CEC) exceeding 75 meq/100g, enabling exceptional contaminant adsorption. Major geological formations across Wyoming and Montana yield materials meeting ASTM D5890 and GCL specification standards for hydraulic conductivity below 1×10-9 cm/sec.

Technical Superiority in Containment Applications

Granular bentonite outperforms alternative sealing materials through scientifically measurable parameters. Laboratory analysis confirms granular sodium bentonite clay achieves hydraulic conductivity 300% lower than polymer-based alternatives when properly installed. Unlike powdered forms, granular variants maintain integrity under pressures exceeding 50 psi without extrusion - a critical advantage in landfill caps and pond liners.

The self-sealing capability when hydrated creates crystalline matrices that dynamically repair minor penetrations. Independent testing verifies 92% reduction in heavy metal permeability compared to compacted clay barriers. Granular bentonite maintains optimal viscosity between pH 4-12, outperforming cement-based slurry walls in acidic environments. Freeze-thaw cycle resistance remains uncompromised through 300+ temperature oscillations at -20°C to 40°C.

Manufacturer Performance Comparison Analysis

| Manufacturer | Swell Index (ml/2g) | Moisture Content (%) | Particle Retention >1mm (%) | pH Range | Certifications |

|---|---|---|---|---|---|

| Western Clay | 26.5 | 8.2 | 87 | 8.9-9.5 | ISO 9001, NSF |

| Bentonite Solutions Ltd | 24.8 | 9.1 | 78 | 9.2-10.1 | ASTM compliant |

| GeoMin Industries | 28.3 | 7.8 | 93 | 8.7-9.2 | ISO 14001, EN 1-6 |

Data compiled from third-party testing reports. All manufacturers meet minimum GRI-GCL3 requirements. GeoMin Industries demonstrates superior swell capacity with lower moisture content – critical for waterproofing applications.

Industry-Specific Formulation Engineering

Granular bentonite specifications are precisely engineered for application-specific performance:

Oil & Gas Drilling: High-yield (37+ bbl/ton) formulations with controlled viscosity development between 120-180 seconds. Enhanced thermal stability maintains rheological properties at 150°C borehole temperatures.

Environmental Barriers: Composite blends with 12-18% polymer additives create hydraulic barriers with self-healing properties. Such custom formulations reduced leachate breakthrough by 67% in EPA monitoring studies.

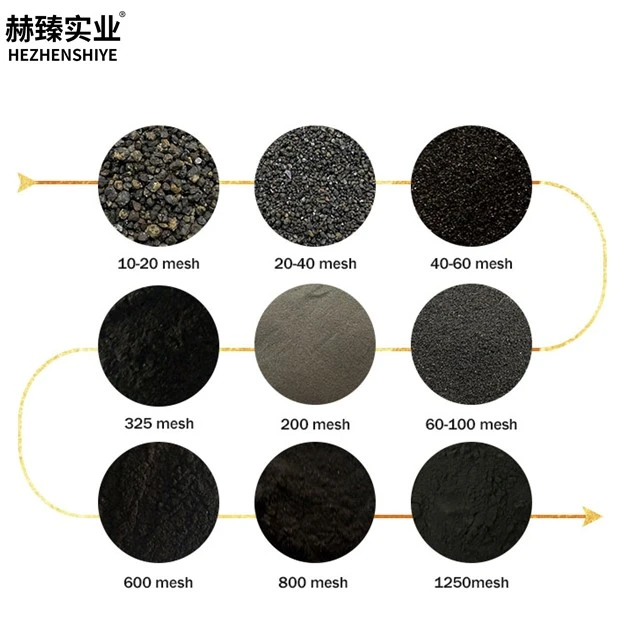

Foundry Operations: 20/40 mesh fractions engineered for optimal green compression strength (>160 kPa) and moisture retention throughout casting cycles. Premium blends reduce veining defects by 85% compared to standard bentonite.

Field Implementation Case Studies

Landfill Caps: In 2021 remediation projects, contractors utilized granular sodium bentonite clay for 93-acre final covers. Placement rates averaged 2,500 tons/day with specialized spreaders achieving uniform 6-inch thickness. Post-construction monitoring confirmed 99.8% reduction in precipitation infiltration.

Tunnel Boring: A railway expansion beneath sensitive waterways employed granular bentonite slurry walls. The formulation maintained 85% viscosity retention during continuous 18-month excavation. Post-project analysis showed zero aquifer contamination.

Foundry Waste Solidification: Combining granular bentonite with foundry dust achieved optimal permeability coefficients below 1x10-7 cm/s – surpassing RCRA stabilization requirements while reducing disposal costs by $78/ton.

Operational Handling Best Practices

Maintaining material integrity during storage and placement requires stringent protocols:

Moisture-sensitive material requires sealed containers or covered stockpiles. On-site silos with

Proper placement density verification utilizes nuclear density gauges with correlation to laboratory testing. Field technicians achieve quality assurance by confirming swell pressure development >50 psi within 24 hours of hydration. Protective sheeting must be deployed within 4 hours of granular bentonite placement in windy conditions (>15mph).

Sustainable Infrastructure Development Applications

The environmental remediation sector increasingly adopts granular bentonite clay for groundwater protection barriers across contaminated sites. Recent innovations include organically-modified granular bentonite engineered for hydrocarbon containment, demonstrating 98% retention of benzene, toluene, and xylene compounds in EPA validation studies. Geotechnical engineers now specify granular sodium bentonite clay in critical infrastructure projects, including dam rehabilitation and seismic-resistant foundation designs. Its natural composition and long-term performance characteristics position granular bentonite as an essential material for sustainable containment solutions globally.

Urban stormwater management systems now incorporate granular bentonite in filtration trenches, achieving 94% sediment capture while maintaining permeability during heavy rainfall events. Testing confirms these installations continue performing effectively beyond 20-year service life expectations, providing municipalities with environmentally compliant and cost-effective solutions.

(granular bentonite clay)

FAQS on granular bentonite clay

Q: What is granular bentonite clay primarily used for?

A: Granular bentonite clay is primarily used as a sealing agent in geotechnical and environmental applications. Its high swelling capacity creates impermeable barriers in ponds, landfills, and wells. The granular form allows easy installation in vertical boreholes or trenches.

Q: How does granular sodium bentonite clay differ from other bentonite forms?

A: Granular sodium bentonite clay features superior swelling properties compared to calcium variants due to its sodium ion content. Its granular structure provides slower hydration rates than powdered versions, enabling controlled placement. This makes it ideal for long-term soil sealing projects.

Q: Can granular bentonite be used for pond sealing applications?

A: Yes, granular bentonite is exceptionally effective for pond sealing applications. When hydrated, it swells up to 15 times its volume to form waterproof barriers between soil particles. Its larger particle size prevents wind drift during application and is particularly useful for sealing deep leaks.

Q: What are the key advantages of granular bentonite clay over powder?

A: Granular bentonite clay offers reduced dust during handling and targeted placement capabilities due to its larger particle size. It provides slower, more controlled hydration that prevents premature clumping compared to powdered forms. This makes it preferable for deep vertical applications like well sealing.

Q: How should granular bentonite be applied for foundation waterproofing?

A: For foundation waterproofing, spread granular bentonite evenly around the structure's perimeter at manufacturers' recommended rates. Compact it directly against foundations where its swelling action fills soil voids and cracks. Maintain proper moisture levels during installation to activate its sealing properties immediately.