The non - metallic mineral products industry is a vast and dynamic sector, with a wide array of companies contributing to various applications, from construction and manufacturing to personal care and environmental solutions. Let's explore some of the key players and product - specific companies within this industry.

Non - Metallic Mineral Products Companies: An Overview

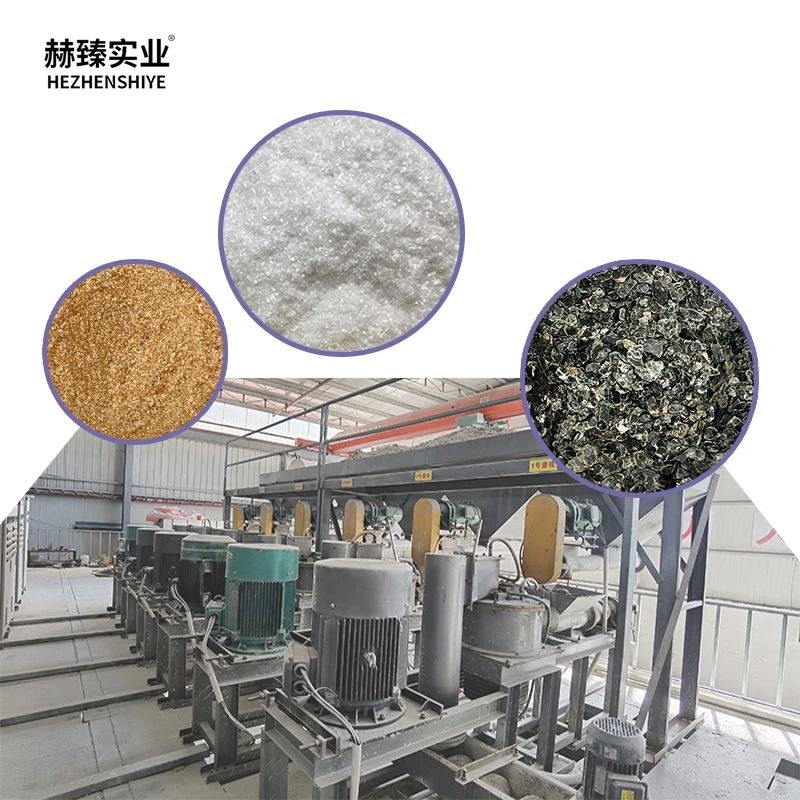

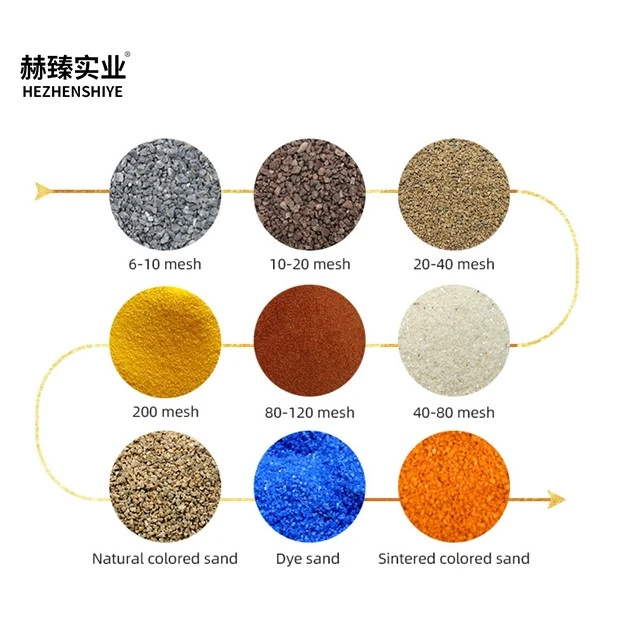

Non - metallic mineral products companies are diverse in their offerings, dealing with materials like clays, sands, gravels, and minerals that are not metals. These companies play a crucial role in multiple industries. For example, in the construction industry, they supply aggregates for concrete production, ensuring the strength and durability of buildings and infrastructure. Some non - metallic mineral products companies focus on processing and distributing minerals used in the manufacturing of glass, ceramics, and plastics. They often engage in mining, beneficiation, and further processing to transform raw non - metallic minerals into value - added products.

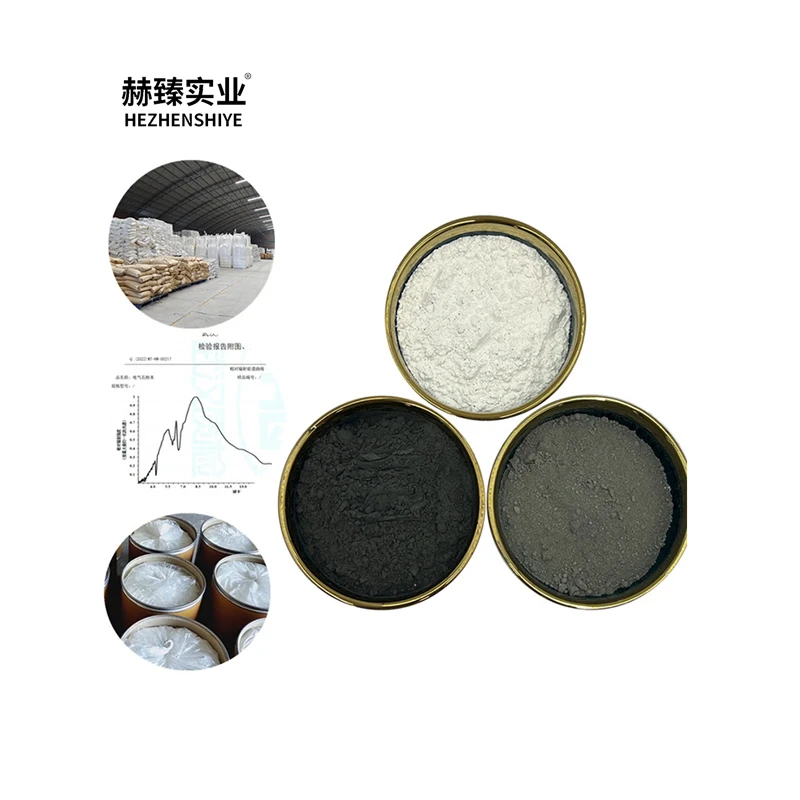

Talc Powder Manufacturers: Precision in Powder Production

Talc powder manufacturers are specialized entities within the non - metallic mineral products space. Talc, a soft mineral composed mainly of magnesium silicate, has numerous applications. In the United States, companies like Atlantic Equipment Engineers, Inc. are notable talc powder manufacturers. They produce talc powder with a boiling point of 1,557 degrees Celsius and 99.9% purity. This high - quality powder is suitable for use in fillers, plastics, paints, paper, rubber, and ceramic applications. Their products serve industries such as cosmetics, aerospace, automotive, and pharmaceuticals. Another player, Reade Advanced Materials, distributes various grades of powdered talc, including those suitable for lubricant, filler, and reinforcement applications. They offer services like size reduction and packaging, catering to the needs of different customers.

Bentonite Suppliers: Meeting Diverse Industry Needs

Bentonite suppliers are essential for industries that rely on this versatile clay. Bentonite, formed from volcanic ash, has unique properties such as swelling in water and excellent colloidal behavior. In India, CMS Industries is one of the largest bentonite mines owners, processors, and exporters. They are ISO 9001:2015 certified and can produce over 9000 Metric Tons of bentonite powder in multiple grades monthly. Their products find use in industries like foundries, where bentonite acts as a binder for sand molds, and in the production of iron ore pellets. In the United States, Lone Star Minerals specializes in providing high - quality bentonite clay for wastewater management and steel foundries, offering immediate delivery from multiple locations.

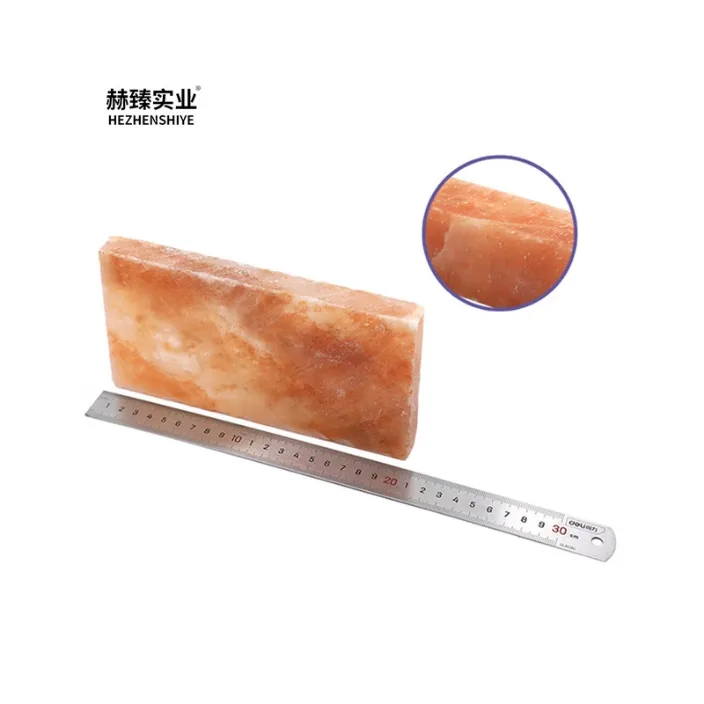

Block Salt Companies: Providing Quality Salt Products

Block salt companies focus on producing and distributing salt in block form, which is commonly used in water softeners. In the United Kingdom, Soft Water Supplies is a well - known family - run company with over 30 years of experience. They deliver high - quality block salt directly to customers' doors. Their British - made block salt is compatible with most major water softener brands, such as Twintec, Harvey's, Minimax, Crown, and Kinetico. The salt blocks are made of very pure salt, with a purity of over 99.9% and comply with EN 973 type A standards. This ensures effective water softening for human consumption and water used in the food industry.

Iron Oxide Pigment Suppliers: Adding Color and Durability

Pembekal pigmen oksida besi are crucial for industries that require pigments for coloring and protection. Iron oxide pigments are widely used in paints, coatings, plastics, and construction materials. Applied Minerals, Inc. is a significant player in this area. They are the leading producer of advanced natural iron oxide solutions from their wholly - owned Dragon Mine property in Utah. These iron oxide pigments not only add vibrant colors but also enhance the durability and weather - resistance of the products they are used in. They can be used in architectural coatings to protect buildings from environmental degradation while providing an aesthetically pleasing finish.

FAQs about Non - Metallic Mineral Products Companies

How do non - metallic mineral products companies ensure product quality?

Non - metallic mineral products companies implement various quality control measures. They often start with careful sourcing of raw materials, ensuring that the minerals are of high purity and quality. For example, talc powder manufacturers may test the mined talc for impurities and ensure that it meets the required specifications for different applications. Bentonite suppliers might conduct tests on the swelling capacity and colloidal properties of the clay. Additionally, many companies are certified to international quality management standards like ISO 9001, which requires them to have well - defined quality management systems in place, from production processes to final product inspection.

What are the main applications of products from these companies?

Products from these companies have a wide range of applications. Talc powder is used in cosmetics for its softening and absorbent properties, in plastics as a filler to improve mechanical properties, and in paints to enhance smoothness and durability. Bentonite is used in drilling muds for oil and gas exploration, as a binder in foundries and iron ore pelletizing, and in cat litter for its absorbent qualities. Block salt is primarily used in water softeners to remove calcium and magnesium ions from water, improving its quality for domestic and industrial use. Iron oxide pigments are used in paints, coatings, and plastics to provide color, as well as in construction materials to enhance their appearance and weather - resistance.

How can one choose a reliable non - metallic mineral products company?

When choosing a reliable non - metallic mineral products company, consider factors such as the company's reputation. Look for customer reviews and testimonials, and check if they have a history of providing high - quality products. Certification is also important; for instance, ISO - certified companies are more likely to adhere to quality and environmental standards. Evaluate their production capacity and ability to meet your specific quantity requirements. Additionally, consider their experience in the industry. A company with years of operation is likely to have refined its processes and have a better understanding of market needs. For example, when choosing a bentonite supplier, a company with decades of experience in mining and processing bentonite is more likely to offer consistent and high - quality products.

Are there environmental concerns associated with non - metallic mineral products companies?

Yes, there can be environmental concerns. Mining of non - metallic minerals can lead to land degradation, habitat destruction, and soil erosion if not properly managed. For example, open - pit mining for talc or bentonite can disrupt local ecosystems. However, many responsible companies implement sustainable mining practices. They may engage in reclamation activities, where the mined land is restored to its original or a usable state after mining. Some companies also focus on reducing waste and energy consumption during the processing of non - metallic minerals. For instance, they might use more energy - efficient equipment or recycle water used in the production process to minimize their environmental footprint.

How do these companies adapt to changing market demands?

Non - metallic mineral products companies adapt to changing market demands in several ways. They invest in research and development to develop new and improved products. For example, as the demand for more sustainable and eco - friendly products grows, talc powder manufacturers may explore ways to produce talc with a lower environmental impact or develop alternative applications for talc. Bentonite suppliers might develop new grades of bentonite with enhanced properties to meet the needs of emerging industries. Additionally, these companies often stay updated with market trends through market research and industry associations. They may also collaborate with customers to understand their evolving requirements and tailor their products and services accordingly.