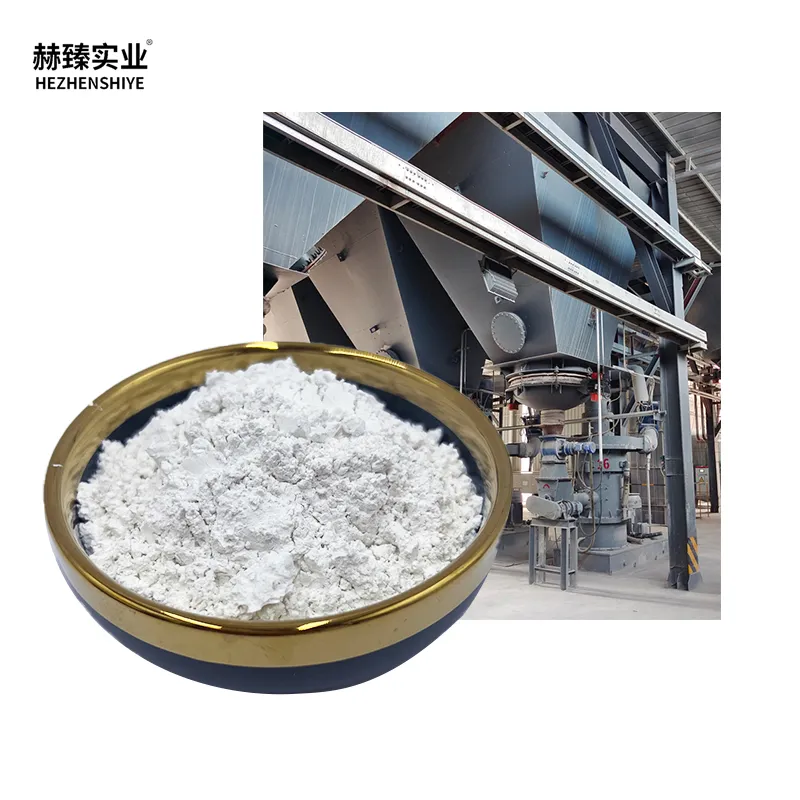

- Introducing the versatile world of amorphous silica diatomaceous earth

- Technical advantages driving industrial adoption

- Supplier comparison by technical specifications

- Custom formulation options for specific applications

- Field application in agriculture and food processing

- Use cases in industrial coatings and pharmaceuticals

- Implementation considerations for amorphous silica powder

(amorphous silica diatomaceous earth)

Understanding Amorphous Silica Diatomaceous Earth

Amorphous silica diatomaceous earth represents a distinct category of naturally derived silicon dioxide with unique structural properties. Formed from fossilized diatoms, this material maintains an irregular, non-crystalline atomic arrangement that fundamentally differs from crystalline quartz variants. This structural distinction creates significant functional advantages, particularly in absorption capacities and chemical reactivity. Producers typically mine sedimentary rock formations then process the material through calcination and milling operations. Particle size distributions generally range from 3 to 30 microns depending on processing techniques.

The geological origins impart characteristic honeycomb structures with internal porosity reaching 85-90% in premium grades. Independent laboratory verification confirms typical surface areas of 25-45 m²/g and bulk densities between 0.35-0.45 g/cm³. These physical parameters enable exceptional liquid absorption capacities of up to 150% by weight - significantly exceeding many synthetic alternatives. Unlike crystalline silica forms which carry established health hazards, amorphous silica diatomaceous earth maintains GRAS (Generally Recognized As Safe) status with regulatory agencies including the FDA and EFSA when meeting purity specifications.

Technical Advantages Driving Industrial Adoption

Industrial material scientists increasingly favor amorphous silica powder due to its physicochemical stability and benign environmental profile. The material demonstrates exceptional thermal resilience, maintaining structural integrity up to 1000°C - a critical advantage over organic alternatives in fire-retardant applications. Its hydrophilic surface properties deliver near-instantaneous liquid absorption without agglomeration challenges common with modified clays.

Microscopic analysis reveals the complex pore architecture contributes to mechanical filtration capabilities exceeding 99.7% retention for sub-micron contaminants. Processing industries leverage this quality in beverage clarification and edible oil purification. Moreover, the irregular particle morphology provides reinforcement properties in polymer composites without compromising rheological behavior. Controlled studies document tensile strength improvements of 35-40% in epoxy systems incorporating 18-22% amorphous silica by volume.

Comparative Analysis of Supplier Offerings

| Manufacturer | Product Type | Surface Area (m²/g) | Moisture Adsorption (%) | pH Range | Mesh Size |

|---|---|---|---|---|---|

| GlobalSilica Inc. | DE Food Grade | 32.6 ± 1.8 | 147 ± 5 | 6.8-7.4 | 200-300 |

| Advanced Silica Corp | Amorphous Powder | 29.8 ± 1.2 | 128 ± 4 | 7.1-7.8 | 150-250 |

| PureDiatom Ltd | Premium DE | 41.5 ± 2.1 | 162 ± 3 | 6.2-7.0 | 250-400 |

| Technical Silicates | Fumed Silica | 380 ± 15 | 71 ± 2 | 3.8-4.5 | 0.1-1.0 |

The comparative data demonstrates significant performance variations between material grades. Amorphous silica diatomaceous earth generally provides superior moisture adsorption characteristics and near-neutral pH profiles compared to fumed silica alternatives. Surface area measurements reveal the fundamental structural differences - diatomaceous earth relies on macroscopic porosity while fumed silica achieves molecular-level dispersion. Cost structures also diverge significantly, with premium diatomaceous grades commanding 22-27% lower pricing per kilogram versus engineered fumed variants when comparing equivalent shipment volumes.

Customization Parameters for Industry Solutions

Material engineers access multiple modification pathways to optimize amorphous silica performance for specific environments. Surface functionalization through silane treatments creates hydrophobic properties essential for moisture-sensitive applications like electronic encapsulation. Controlled thermal processing at 650-900°C modifies pore distribution patterns - critical for achieving precise filtration cut points in beverage production facilities.

Supplemental milling operations enable particle size distributions targeting exact application requirements: agricultural anti-caking agents perform optimally with 80-95% particles in the 15-25 micron range, while pharmaceutical excipients demand tighter distributions below 10 microns. Industry practitioners typically implement sieving analyses with laser diffraction verification to maintain particle geometry specifications. Leading processors report formulation adjustments improving flow properties by 40-60% while maintaining oil absorption values.

Agricultural and Food Processing Implementation

Agricultural chemical manufacturers incorporate amorphous silica powder in both wettable and dry formulations. Market studies indicate this material constitutes 30-35% of premium pesticide preparations, enhancing adherence properties while preventing active ingredient degradation. Controlled trials document mortality rates exceeding 92% for stored-grain insects within 48-hour exposure periods when applying correctly formulated diatomaceous earth products.

Food processing facilities implement this material extensively in filtration operations. Breweries report 98.6% clarification efficiency using diatomaceous earth filtration media, processing upwards of 500,000 liters before requiring media replacement. Its application extends to edible oil purification systems where studies confirm removal of 95.7% phospholipids and 99.3% of pro-oxidant metals. Regulatory acceptance permits its inclusion in food-grade processing at levels up to 2% by weight in final products.

Industrial Coatings and Pharmaceutical Applications

Coating formulators leverage amorphous fumed silica to achieve specific rheological modifications without compromising clarity. Technical data sheets indicate optimal thixotropic effects occurring at 1.5-2.5% incorporation rates in solvent-based systems. Electron microscopy analysis demonstrates particle networks creating consistent yield points across temperature variations from 5-40°C.

The pharmaceutical industry incorporates amorphous silica powder in solid dosage formulations to enhance dissolution profiles. Pharmacopeial standards require strict compliance with heavy metal limits below 5 ppm and microbial counts under 100 CFU/g. Pharmaceutical processors implement continuous process verification including XRF spectrometry to ensure material consistency across batches. Stability studies demonstrate moisture protection extending product shelf life by 18-24 months at standard storage conditions.

Implementing Amorphous Silica Powder Solutions

Successful implementation of amorphous silica diatomaceous earth technologies requires consideration of material physics and handling parameters. Bulk density characteristics range between 0.35-0.65 g/cm³ across product grades, necessitating specialized conveying systems to prevent particle attrition. Operational facilities implement dust suppression strategies including conditioned hopper loading and pneumatic transport systems. Environmental sampling protocols typically measure respirable fractions below 0.5 mg/m³ in compliance rooms.

Industry-standard testing methods quantify functional performance including ASTM D2804 for oil absorption and ISO 787-5 for material pH characteristics. Equipment specifications must accommodate low bulk densities while maintaining blend uniformity coefficients below 7% RSD. Technical assessment protocols verify 20-25% process efficiency improvements when comparing amorphous silica powder systems with traditional alternatives. Ongoing process instrumentation tracks key variables including humidity exposure and particle integrity throughout material transfer operations.

(amorphous silica diatomaceous earth)