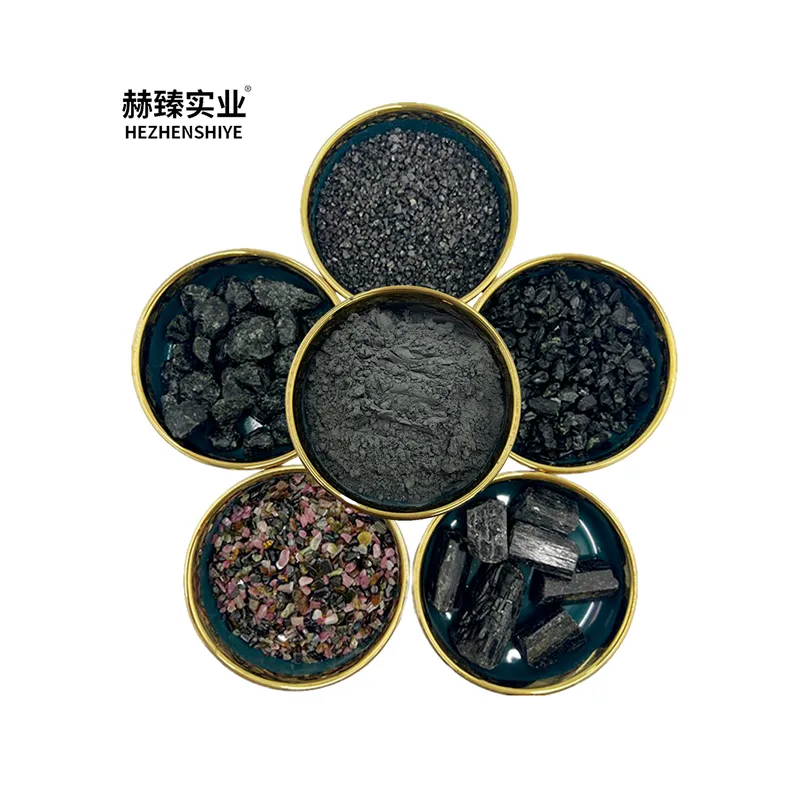

Hezhen Park road luminous stone fluorescent runway stone high luminous gravel garden fish tank

2025.03.06

Understanding the intricacies of bentonite pricing and its market dynamics can significantly impact decision-making for industries ranging from construction to pharmaceuticals. As businesses worldwide strive to optimize their supply chains, knowing the cost per ton of bentonite becomes crucial. However, several factors underpin these costs, influencing the bentonite market profoundly.

The method of processing and refining bentonite further impacts its final cost. Crude bentonite requires extensive processing to reach the desired quality, involving a series of steps including drying, milling, and packaging. These processes not only enhance the properties of bentonite but also increase its market value. Companies that invest in state-of-the-art processing techniques often command a premium for their products, justified by the resultant quality and performance consistency. Market demand, driven by industries such as construction, agriculture, and cosmetics, also plays a significant role. During periods of high demand, prices can surge due to the increased competition for high-quality bentonite. Conversely, economic downturns can lead to a decrease in demand, lowering prices. Additionally, environmental regulations and mining restrictions can impact both the availability and cost of bentonite. Stricter regulations may lead to increased operational costs for mining companies, which are often passed on to consumers. Engaging with reputable suppliers who have an extensive track record and a commitment to quality assurance can provide businesses with the assurance of receiving consistent, reliable bentonite. These suppliers often provide transparency in their pricing structures, offering breakdowns that detail how logistical, processing, and market dynamics contribute to the final cost. In conclusion, the price per ton of bentonite is the culmination of various factors that range from geological to geopolitical. Those in the procurement and supply chain sectors must undertake a comprehensive analysis of these elements to make informed decisions. By understanding the underlying dynamics of bentonite pricing, businesses not only secure supply chain stability but also gain a competitive edge, optimizing their operations and improving profitability. Emphasizing a relationship with trustworthy suppliers can further bolster the integrity of these operations, ensuring excellence and reliability in every interaction.

The method of processing and refining bentonite further impacts its final cost. Crude bentonite requires extensive processing to reach the desired quality, involving a series of steps including drying, milling, and packaging. These processes not only enhance the properties of bentonite but also increase its market value. Companies that invest in state-of-the-art processing techniques often command a premium for their products, justified by the resultant quality and performance consistency. Market demand, driven by industries such as construction, agriculture, and cosmetics, also plays a significant role. During periods of high demand, prices can surge due to the increased competition for high-quality bentonite. Conversely, economic downturns can lead to a decrease in demand, lowering prices. Additionally, environmental regulations and mining restrictions can impact both the availability and cost of bentonite. Stricter regulations may lead to increased operational costs for mining companies, which are often passed on to consumers. Engaging with reputable suppliers who have an extensive track record and a commitment to quality assurance can provide businesses with the assurance of receiving consistent, reliable bentonite. These suppliers often provide transparency in their pricing structures, offering breakdowns that detail how logistical, processing, and market dynamics contribute to the final cost. In conclusion, the price per ton of bentonite is the culmination of various factors that range from geological to geopolitical. Those in the procurement and supply chain sectors must undertake a comprehensive analysis of these elements to make informed decisions. By understanding the underlying dynamics of bentonite pricing, businesses not only secure supply chain stability but also gain a competitive edge, optimizing their operations and improving profitability. Emphasizing a relationship with trustworthy suppliers can further bolster the integrity of these operations, ensuring excellence and reliability in every interaction.