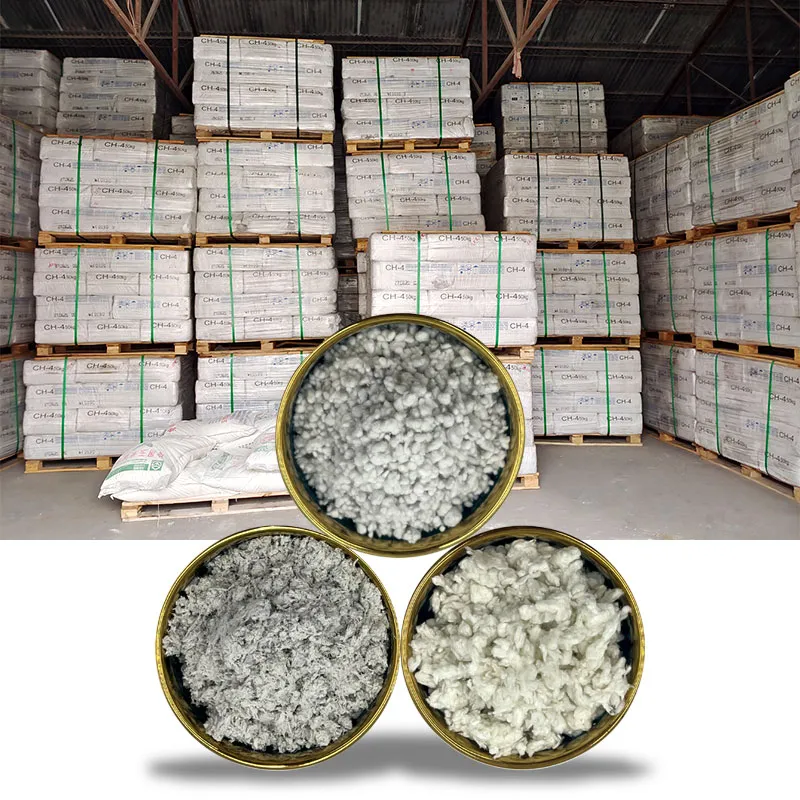

calcined kaolin powder

2025.02.13

Calcined kaolin powder, a highly refined form of kaolin clay, has shown profound advancements in various industrial applications, emphasizing the importance and quality of this material. Through advanced thermal processing, the kaolin's structure is altered to improve properties such as whiteness and hardness, rendering it especially useful in industries such as paint, rubber, paper, and ceramics.

Environmental sustainability is becoming a priority across industries, and calcined kaolin powder offers a compelling solution. Its production process and end-use applications pose minimal environmental impact, aligning with green manufacturing practices. The reduced energy requirement in its processing and its role in lessening reliance on synthetic additives contribute positively to sustainability objectives. Furthermore, its potential for recycling within production processes further extends its ecological benefits, making it a material of choice for environmentally conscious manufacturers. Experts recognize calcined kaolin powder as a versatile solution for contemporary industrial needs. Continuous innovations in processing technologies enhance its applicability, supporting new and existing products. Trust in its usage is bolstered through comprehensive quality assessments and certifications from leading regulatory bodies, assuring end-users of its safety and efficacy. For businesses seeking a dependable partner in their production processes, calcined kaolin powder delivers not just on quality but also on performance and cost-efficiency. Integrating this material into product lines provides competitive advantages backed by scientific research and real-world results. In conclusion, calcined kaolin powder emerges as a material that stands the test of quality, reliability, and sustainability across various industries. Its proven benefits in improving product performance and compliance with eco-friendly standards cement its position as an indispensable component in manufacturing innovation. Companies intent on achieving excellence and sustainability in their product offerings should consider the integration of this remarkable substance into their production repertoire.

Environmental sustainability is becoming a priority across industries, and calcined kaolin powder offers a compelling solution. Its production process and end-use applications pose minimal environmental impact, aligning with green manufacturing practices. The reduced energy requirement in its processing and its role in lessening reliance on synthetic additives contribute positively to sustainability objectives. Furthermore, its potential for recycling within production processes further extends its ecological benefits, making it a material of choice for environmentally conscious manufacturers. Experts recognize calcined kaolin powder as a versatile solution for contemporary industrial needs. Continuous innovations in processing technologies enhance its applicability, supporting new and existing products. Trust in its usage is bolstered through comprehensive quality assessments and certifications from leading regulatory bodies, assuring end-users of its safety and efficacy. For businesses seeking a dependable partner in their production processes, calcined kaolin powder delivers not just on quality but also on performance and cost-efficiency. Integrating this material into product lines provides competitive advantages backed by scientific research and real-world results. In conclusion, calcined kaolin powder emerges as a material that stands the test of quality, reliability, and sustainability across various industries. Its proven benefits in improving product performance and compliance with eco-friendly standards cement its position as an indispensable component in manufacturing innovation. Companies intent on achieving excellence and sustainability in their product offerings should consider the integration of this remarkable substance into their production repertoire.

Pervious