Drilling operations require precision, efficiency, and reliability to ensure safe and successful outcomes. Among the critical components of drilling fluids, drilling bentonite plays a pivotal role in maintaining wellbore stability and optimizing performance. This article explores the unique properties, advantages, and applications of bentonite drilling mud, with a focus on calcium-base and sodium-base bentonite drilling briquettes manufactured by Hebei Hezhen Industry Co., Ltd..

Introduction to Bentonite and Its Role in Drilling

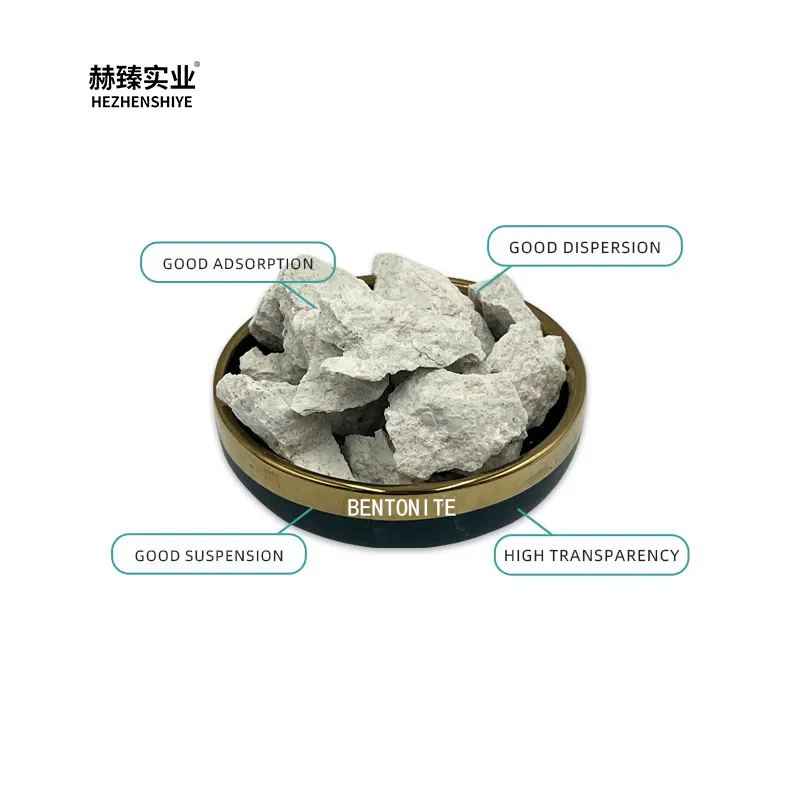

Bentonite, a naturally occurring clay mineral, is renowned for its ability to swell and form a viscous gel when hydrated. This unique property makes it an ideal component for bentonite drilling mud, as it helps stabilize the wellbore, seal permeable formations, and carry cuttings to the surface. However, traditional loose bentonite powder can be cumbersome to handle, leading to the development of drilling briquettes, which offer improved convenience and performance.

Advantages of Drilling Briquettes

Compared to loose bentonite powder, drilling briquettes provide several advantages:

- Enhanced Handling: Briquettes reduce dust exposure and spillage risks, making them safer and easier to transport and store.

- Consistent Performance: Their uniform composition ensures predictable results, critical for complex drilling operations.

- Cost-Effectiveness: By minimizing waste and improving efficiency, briquettes offer long-term economic benefits.

Calcium-Base vs. Sodium-Base Bentonite: Key Differences

The choice between calcium-base and sodium-base bentonite depends on specific drilling conditions:

- Calcium-Base Bentonite: Known for high gel strength and temperature stability, it is ideal for deeper and hotter wells. This makes it suitable for polymer bentonite drilling mud applications where thermal resistance is critical.

- Sodium-Base Bentonite: Offers superior fluid loss control and thixotropic properties, essential for maintaining wellbore stability in varied drilling environments.

Technical Specifications of Hezhen Drilling Briquettes

| Feature | Details |

|---|---|

| Place of Origin | China |

| Color | White/Yellow |

| Shape | Powder |

| Purity | 90-95% |

| Grade | Industrial Grade, Food Grade |

| Packaging | 25kg/bag, Customized Package |

| MOQ | 1kg |

Applications in the Drilling Industry

Bentonite drilling mud is widely used in various drilling scenarios, including:

- Oil and Gas Drilling: Stabilizing wellbores in high-temperature environments.

- Geothermal Energy: Enhancing fluid loss control in deep, high-pressure wells.

- Construction and Mining: Preventing soil collapse during excavation.

Company Background: Hebei Hezhen Industry Co., Ltd.

Based in China, Hebei Hezhen Industry Co., Ltd. is a leading provider of bentonite drilling briquettes. The company specializes in supplying high-quality industrial and food-grade bentonite products, catering to global markets. With a commitment to innovation and quality, Hezhen ensures that its products meet rigorous standards for performance and safety.

Ensuring Quality and Compliance

As highlighted by the National Institute of Standards and Technology (NIST), adherence to standardized testing and measurement protocols is critical in the drilling industry. Hezhen’s products are engineered to comply with international standards, ensuring reliability and consistency. For further insights into industry standards, visit NIST's official website.

Conclusion

Drilling briquettes made from calcium-base and sodium-base bentonite are indispensable for optimizing drilling performance. Whether in oil and gas exploration, geothermal energy, or construction, these products offer unmatched advantages in stability, efficiency, and safety. By choosing Hebei Hezhen Industry Co., Ltd., customers gain access to cutting-edge solutions backed by rigorous quality control and industry expertise.

References

National Institute of Standards and Technology (NIST). (n.d.). Retrieved from https://www.nist.gov/