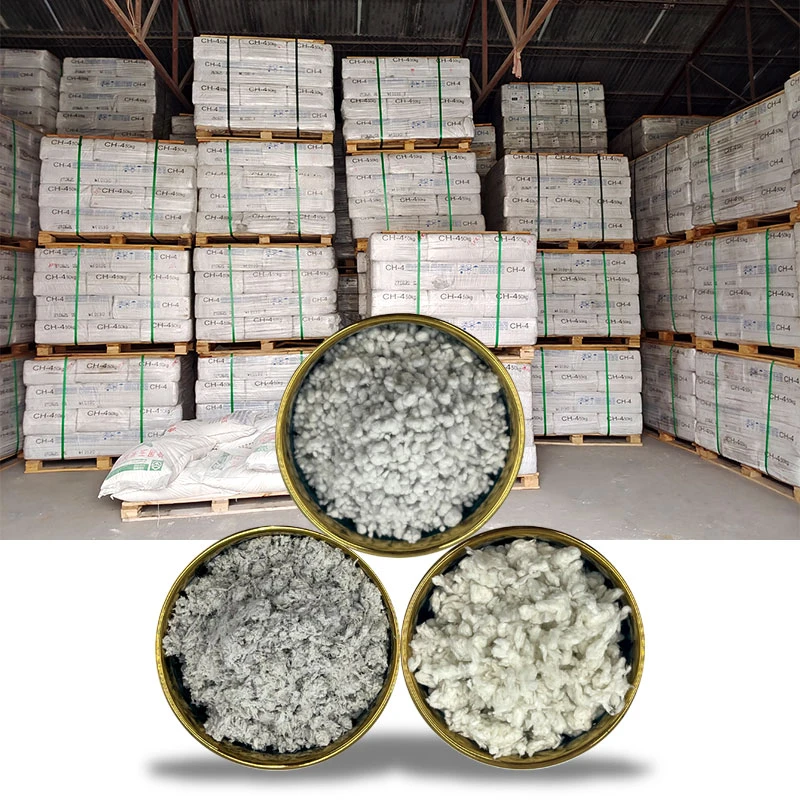

colloidal silicon dioxide used in tablet formulation

2025.01.13

Colloidal silicon dioxide, often recognized as an essential ingredient in tablet formulation, provides multiple benefits pivotal to the pharmaceutical industry, enhancing both the manufacturing processes and the quality of the final product.

Trustworthiness stems from the consistent results observed with the inclusion of colloidal silicon dioxide across various formulation types—from directly compressed tablets to those requiring wet granulation techniques. Operational experts have noted that its addition optimizes tooling performance, reducing machine downtime caused by problematic powder blends. Furthermore, routine quality assurance protocols demonstrate the excipient's non-volatile properties, with consistent results achieved through repeated analytical testing such as particle size distribution and moisture content analysis. When considering the integration of colloidal silicon dioxide in tablet formulation, it’s apparent that this excipient is indispensable for its ability to streamline manufacturing operations while enhancing product quality. Utilizing such additives responsibly and innovatively enables pharmaceutical companies to not only meet regulatory standards but also extend their product portfolios with reliable, high-quality medications. As the industry evolves, maintaining reliance on scientifically validated excipients like colloidal silicon dioxide ensures that manufacturers continue to deliver efficacious and safe pharmaceuticals to the global market. In conclusion, the utilization of colloidal silicon dioxide in tablet formulation is underscored by hands-on experience, deep chemical expertise, authoritative validation, and a trustworthy safety record. It remains a cornerstone in pharmaceutical formulation science, playing a critical role in the development of consistent, effective medicinal products. For professionals in the pharmaceutical manufacturing sector, incorporating colloidal silicon dioxide is both a testament to quality assurance and a strategy for enhanced operational efficacy.

Trustworthiness stems from the consistent results observed with the inclusion of colloidal silicon dioxide across various formulation types—from directly compressed tablets to those requiring wet granulation techniques. Operational experts have noted that its addition optimizes tooling performance, reducing machine downtime caused by problematic powder blends. Furthermore, routine quality assurance protocols demonstrate the excipient's non-volatile properties, with consistent results achieved through repeated analytical testing such as particle size distribution and moisture content analysis. When considering the integration of colloidal silicon dioxide in tablet formulation, it’s apparent that this excipient is indispensable for its ability to streamline manufacturing operations while enhancing product quality. Utilizing such additives responsibly and innovatively enables pharmaceutical companies to not only meet regulatory standards but also extend their product portfolios with reliable, high-quality medications. As the industry evolves, maintaining reliance on scientifically validated excipients like colloidal silicon dioxide ensures that manufacturers continue to deliver efficacious and safe pharmaceuticals to the global market. In conclusion, the utilization of colloidal silicon dioxide in tablet formulation is underscored by hands-on experience, deep chemical expertise, authoritative validation, and a trustworthy safety record. It remains a cornerstone in pharmaceutical formulation science, playing a critical role in the development of consistent, effective medicinal products. For professionals in the pharmaceutical manufacturing sector, incorporating colloidal silicon dioxide is both a testament to quality assurance and a strategy for enhanced operational efficacy.