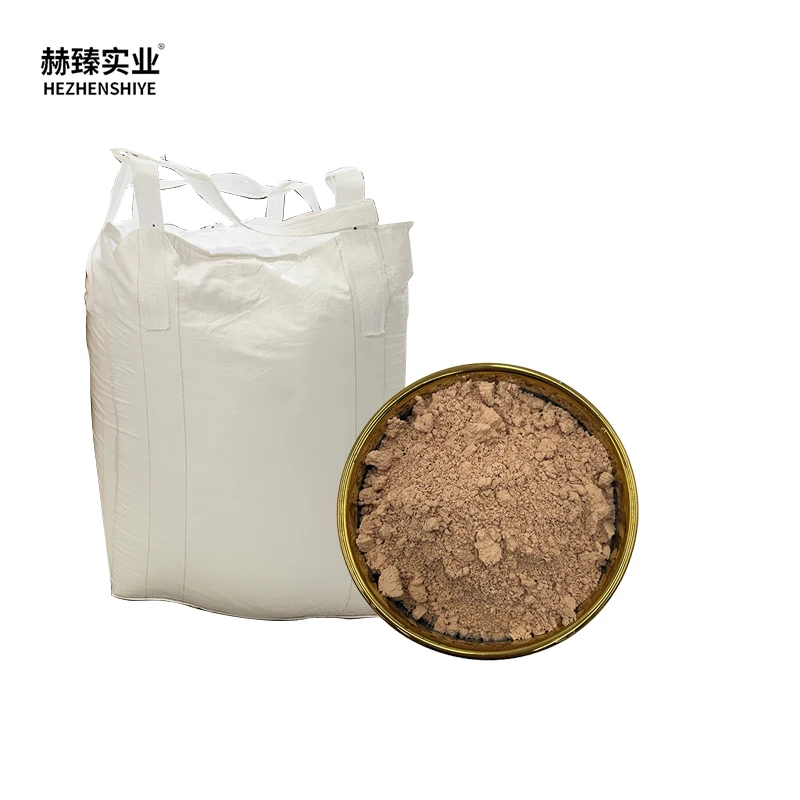

fumed silica for sale

2025.01.10

Navigating the complex world of chemical additives, fumed silica emerges as an indispensable resource across various industries, revered for its versatile applications and exceptional characteristics. For businesses seeking to heighten their production processes, understanding the nuances of fumed silica not only unlocks substantial benefits but also optimizes operational efficiency. This article delves into the core aspects of fumed silica, underpinned by real-world applications and expert insights, to guide informed purchasing decisions.

Trustworthiness in the manufacture and sale of fumed silica is critical. Reputable suppliers are transparent about sourcing and processing, providing detailed specifications, safety data sheets (SDS), and compliance with rigorous international standards. This transparency fosters confidence among buyers, knowing that the product meets stringent quality controls and regulatory requirements. Partnering with such suppliers aids businesses in minimizing risks associated with chemical procurement and usage. Furthermore, innovations in the field have propelled fumed silica to the forefront of sustainable advancement. As industries pivot towards environmentally friendly practices, novel applications are continually evolving. The development of low-VOC (volatile organic compound) systems in paints and sustainable composites in construction are examples where fumed silica’s technology fosters innovation, aligning production with global sustainability goals. In essence, fumed silica's market availability is not merely about acquisition but involves the strategic selection based on in-depth expertise, authoritative recommendations, and established trust with suppliers. For organizations aiming to integrate fumed silica into their production lines, considering these facets equips them with the knowledge to leverage this compound's full potential, ensuring enhanced product quality and market competitiveness. With its proven track record across domains, fumed silica remains an exemplary model of how tailored chemical solutions drive industry progression and innovation.

Trustworthiness in the manufacture and sale of fumed silica is critical. Reputable suppliers are transparent about sourcing and processing, providing detailed specifications, safety data sheets (SDS), and compliance with rigorous international standards. This transparency fosters confidence among buyers, knowing that the product meets stringent quality controls and regulatory requirements. Partnering with such suppliers aids businesses in minimizing risks associated with chemical procurement and usage. Furthermore, innovations in the field have propelled fumed silica to the forefront of sustainable advancement. As industries pivot towards environmentally friendly practices, novel applications are continually evolving. The development of low-VOC (volatile organic compound) systems in paints and sustainable composites in construction are examples where fumed silica’s technology fosters innovation, aligning production with global sustainability goals. In essence, fumed silica's market availability is not merely about acquisition but involves the strategic selection based on in-depth expertise, authoritative recommendations, and established trust with suppliers. For organizations aiming to integrate fumed silica into their production lines, considering these facets equips them with the knowledge to leverage this compound's full potential, ensuring enhanced product quality and market competitiveness. With its proven track record across domains, fumed silica remains an exemplary model of how tailored chemical solutions drive industry progression and innovation.

Pervious