fumed silica price per ton

2025.01.13

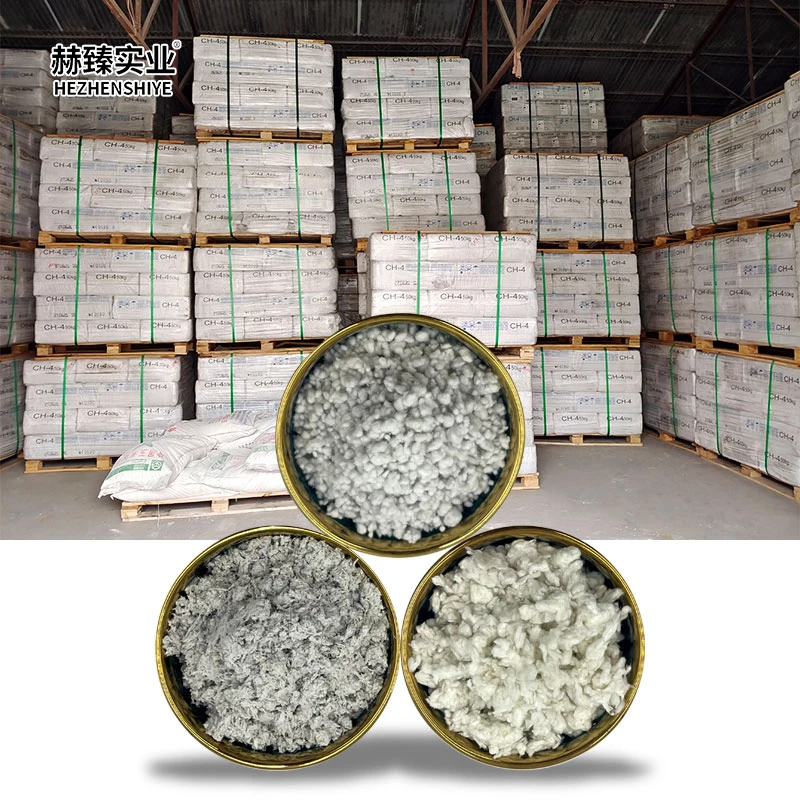

For businesses in industries ranging from cosmetics to construction, the fluctuation in the price of fumed silica can have a significant impact on operations and profitability. The market for fumed silica is complex, influenced by various factors including supply chain dynamics, raw material costs, and global demand trends. Understanding these factors can provide companies with strategic insight into purchasing practices and budgeting.

Moreover, regulatory considerations are a vital component, with environmental regulations influencing both production costs and market supply. Compliance with strict regulations can lead to additional expenses in waste processing and emission controls, thereby impacting unit prices. Collaborative relationships with suppliers can mitigate some of these variabilities. By engaging in long-term contracts or partnerships, businesses may secure more stable pricing, providing them with budget predictability and competitive advantages in their respective markets. Additionally, leveraging a diversified supplier base minimizes risk associated with supply chain disruptions. Strategically benchmarking against industry price indexes and participating in industry groups can also foster a deeper understanding of market trends, enabling companies to make more informed purchase decisions. Regular communication with suppliers and market experts aids in early detection of potential price changes, allowing for proactive adjustments in procurement strategies. Ultimately, while the price of fumed silica per ton can be influenced by numerous factors, a comprehensive understanding of the market—and a proactive, informed approach to procurement—can help organizations navigate these complexities successfully. Investing in market research, maintaining flexibility in supplier relationships, and adopting advanced technological solutions can lead to more effective management of material costs, ensuring both sustainability and profitability in a competitive global market.

Moreover, regulatory considerations are a vital component, with environmental regulations influencing both production costs and market supply. Compliance with strict regulations can lead to additional expenses in waste processing and emission controls, thereby impacting unit prices. Collaborative relationships with suppliers can mitigate some of these variabilities. By engaging in long-term contracts or partnerships, businesses may secure more stable pricing, providing them with budget predictability and competitive advantages in their respective markets. Additionally, leveraging a diversified supplier base minimizes risk associated with supply chain disruptions. Strategically benchmarking against industry price indexes and participating in industry groups can also foster a deeper understanding of market trends, enabling companies to make more informed purchase decisions. Regular communication with suppliers and market experts aids in early detection of potential price changes, allowing for proactive adjustments in procurement strategies. Ultimately, while the price of fumed silica per ton can be influenced by numerous factors, a comprehensive understanding of the market—and a proactive, informed approach to procurement—can help organizations navigate these complexities successfully. Investing in market research, maintaining flexibility in supplier relationships, and adopting advanced technological solutions can lead to more effective management of material costs, ensuring both sustainability and profitability in a competitive global market.

Pervious

Next