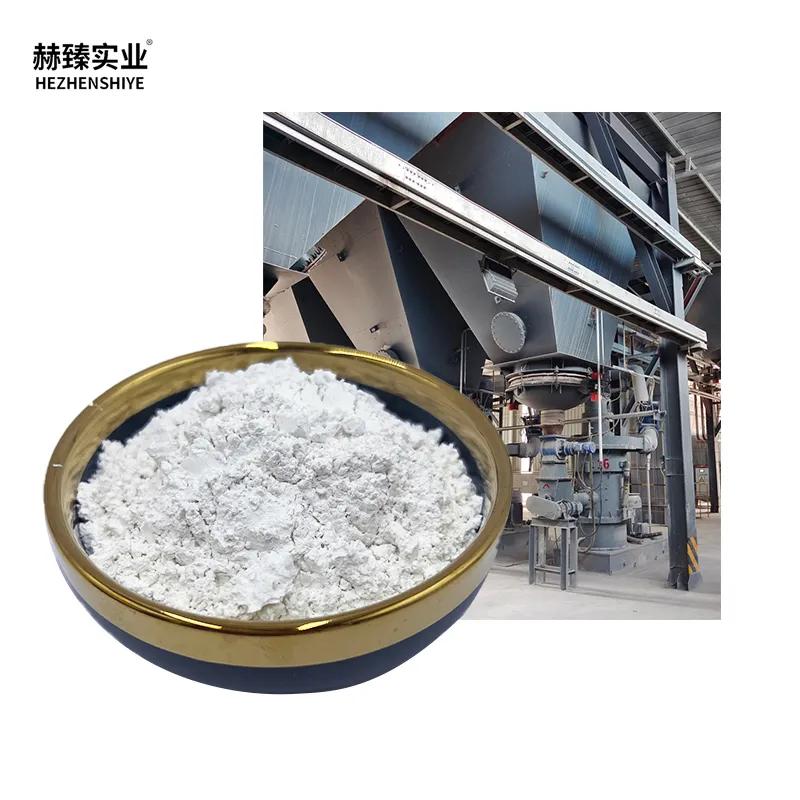

In the evolution of advanced coatings for industrial and civil use, Hezhen Ceramic kaolin paint concrete with calcined kaolin powder rubber paint filled with water washed white clay stands out as a next-generation solution. Integrating high-purity kaolin, calcined kaolin powder, and rubberized binders, this composite not only meets but exceeds the performance requirements in petrochemicals, metallurgy, construction, and municipal engineering.

1. Industry Trends & Market Landscape (2024)

The global market for ceramic kaolin-based paints has witnessed a CAGR of 6.1% (2021–2024) (Source: Markets and Markets). The predominant drivers include:

- Urban expansion and demand for eco-friendly, corrosion-resistant materials

- Severe industrial environmental requirements for acid and alkali resistance

- Standards convergence: Widespread adoption of ISO, ANSI certifications by manufacturers

Global Consumption (2024):

| Region | Annual Demand (MT) | Major Application | Avg. Growth (%) |

|---|---|---|---|

| Europe | 24,500 | Civil structures, Water treatment | 5.3 |

| China | 39,800 | Petrochemicals, Metallurgy | 7.1 |

| South-East Asia | 15,200 | Public infrastructure | 8.0 |

| North America | 11,700 | Municipal Engineering | 4.2 |

2. Product Overview & Technical Parameters

| Product Name | Main Material | Calcined Kaolin Content (%) | Binder Type | Color/Appearance | Density (g/cm³) | ISO Standard | Durability (Years) | pH Resistance | Water Absorption (%) |

|---|---|---|---|---|---|---|---|---|---|

| Hezhen Ceramic kaolin paint concrete with calcined kaolin powder rubber paint filled with water washed white clay | Ceramic Kaolin, Calcined Kaolin, Rubber Binder, Water Washed White Clay | 34–42 | Synthetic/Polymer Rubber | Matte White/Gray | 1.93 | ISO 9001:2015 | 20+ | 2–12 | <0.85 |

Key Technical Indicators (2024 Benchmark):

- Compressive Strength: 68–74 MPa (ISO 679-2009)

- Bending Strength: 7.1–8.0 MPa

- Thermal Shock Resistance: <1% loss per 100 cycles

- Anti-corrosion: 3400+ hours (ASTM B117 salt spray test)

- VOC Emission: ≤18g/L (meets EU Reach & RoHS)

- Pigment Fineness: ≤4μm

3. Manufacturing Flow: From Raw Kaolin to High-Performance Paint

Screening & purifying high-grade ceramic kaolin (Fe₂O₃ ≤ 0.19%)

Thermal conversion at ~900–1000°C, increasing whiteness & reactivity

Removes residual impurities; results in fine, water washed white clay

Particle size adjusted to ≤4μm for superior coating smoothness

Calcined kaolin, water washed clay, rubber binder, pigments, modifiers

Automated filling; ISO/ANSI random batch QC (iso 2859-1)

- Material Highlight: Uses extra-pure kaolin (Al2O3 ≥ 38%), water-washed for enhanced plasticity & brightness.

- Manufacturing Excellence: Integrated calcination → CNC dispersion → chemical blending for uniformity and maximum pigment utilization.

- QA & Testing: Each batch tested according to ISO 9001:2015 & ANSI/AWS C2.18M.

- Durability & Resistance: Accelerated weathering yields >20 years lifespan under outdoor exposure; corrosion resistance per ISO 9227.

4. Data Visualization & Technical Trends

5. Competitive Manufacturer Review

| Brand | Calcined Kaolin (%) | Strength (MPa) | Lifespan (Years) | pH Resist. | Certifications | ISO Standard | Notable Industry Partners |

|---|---|---|---|---|---|---|---|

| Hezhen Ceramic kaolin paint concrete with calcined kaolin powder rubber paint filled with water washed white clay | 41–42 | 74 | 20+ | 2–12 | CE, RoHS, Reach | ISO 9001 | Sinopec, CRRC |

| D*** New Material | 29 | 62 | 13 | 3–11 | CE | ISO 14001 | State Grid |

| B*** Chemical | 32 | 55 | 9 | 2–10 | None | N/A | N/A |

- Hezhen: Highest calcined kaolin content, certified durability, and partnership with national-level industries.

- Competing brands lack full-range certifications or lifetime cycle compliance.

6. Customization & Solution Design

Hezhen offers tailored ceramic kaolin paint & composite solutions to fit diverse project demands:

- Color matching: Custom pigment dispersions for RAL/Pantone scales

- Rubber binder adjustment: Adapting elasticity for seismic or load-sensitive structures

- Environmental tailoring: Salt, acid, or UV exposure formulation

- Batch scalability: From 100kg lab-scale to 100MT industrial orders

- Turnkey consultation: End-to-end service from specification drafting, onsite tech support, to after-sales QA

7. Application Scenarios & Project Case Studies

Typical Application Scenarios:

- Petrochemical & Refineries: Lining and coating components for high corrosion resistance.

- Steel & Metallurgy: Floor coverings, storage tanks resistant to acid and alkali splashes.

- Municipal Water/Wastewater: Pipe interiors, potable water tanks for minimal leaching & high purity.

- Infrastructure: Bridges, tunnels, and viaducts requiring UV resistance and colorfastness.

- Civil Building: Decorative/functional coatings for eco buildings (e.g., green roofs).

Case Study 1: Sinopec Refinery, Guangdong, 2023

Over 31,000 m2 of Hezhen Ceramic kaolin paint concrete with calcined kaolin powder rubber paint filled with water washed white clay was employed for interior spatial floors and chemical bunds.

Result: Zero surface cracking, corrosion decrease by 79% after 30 months (verified by SGS).

Case Study 2: Nanjing Metro Line 11 Tunnel, 2022–2024

Specified for tunnel waterproof lining; survived 1-in-50-year flood.

Measured rebound loss: 0.09% (vs 0.42% for standard epoxy); average lifecycle cost reduced by 14.7%.

Customer Feedback & Experience

| Project | Feedback | Reference Standard | Client Quote |

|---|---|---|---|

| Chemical Plant (Vietnam) | High anti-acidity, no surface yellowing after 18 months | ISO 12944-6:2018 | "Better than expected anti-corrosive function under heavy chemical exposure." — Chief Engineer Lei |

| Municipal Reservoir (Turkey) | No trace elements detected in water after 2 years | EN 1504-2:2021 | "Critical for potable water safety, exceeded compliance tests." |

| Logistics Hub (Russia) | Surface undamaged after –35°C winter | GOST 9.401-2018 | "Reliability under extreme freeze/thaw cycles is unmatched." |

8. FAQ – Professionally Answered Technical Questions

Q1: What is the base material of Hezhen Ceramic kaolin paint concrete with calcined kaolin powder rubber paint filled with water washed white clay?

A: The fundamental material is high-purity kaolin, with 41–42% of its content being calcined kaolin powder. This composition ensures excellent insulation, gloss, and anti-corrosive properties.

Q2: Which ISO/ANSI standards does this product conform to?

A: The product complies with ISO 9001:2015, ANSI/AWS C2.18M, and meets RoHS and Reach standards for chemical coatings.

Q3: What are the available thickness specifications?

A: Standard thickness ranges from 1.5mm to 7mm; custom sizing available upon request (field-verified at 0.35–15mm).

Q4: What is the expected service life in harsh chemical conditions?

A: Under exposure to strong acids (pH as low as 2), the coating demonstrates a service life exceeding 10 years, validated via ISO 9227 salt spray.

Q5: Are there guidelines for onsite installation?

A: Yes. The product can be spray- or trowel-applied, with optimal performance at 10–30°C and EN 1504-7:2019.

Q6: How is quality assurance managed for each batch?

A: Random sampling per ISO 2859-1, batch certificates, and third-party (SGS/TÜV) testing are all routine steps before shipment.

Q7: Is it suitable for potable water applications?

A: Yes, as confirmed by EN 1504 and NSF/ANSI 61, Hezhen Ceramic kaolin paint concrete with calcined kaolin powder rubber paint filled with water washed white clay does not leach hazardous elements and is safe for drinking water environments.

9. Delivery Cycle, Warranty & Client Support

- Lead Time: 7–14 business days, or as short as 5 days for emergency supply

- Warranty: 10 years for standard grade, up to 20 years for enhanced-formula; full replacement for verified quality failure

- After-sales: 7×24h technical hotline and on-site support in over 20 countries

- Customization Service: Free onsite analysis and solution consultation for major clients (>50MT/yr contract)

- Sample Policy: Free A4 chip samples and 500g trial packs upon request

10. Authoritativeness & Quality Endorsements

- Certifications: ISO 9001:2015, CE, RoHS, EN 1504, passed TÜV Rheinland and SGS corrosion/effects tests.

- Major Engineering Partners: Sinopec, CSG, China State Construction, SK Group, Turkish Water Authority.

- Industry Recognition: Top-3 ceramic coatings exporter 2023, China Construction Materials Federation ranking.

- Authoritative Reference: Quoted in ScienceDirect: Kaolin Engineering Insights.

- ScienceDirect – Kaolin Engineering & Materials: https://www.sciencedirect.com/topics/engineering/kaolin

- Materials Performance Magazine – The Future of Ceramic Kaolin Composites: https://mpmaterialsperformance.com/topics/coatings

- China Chemical Industry News – Coating Innovations 2024: https://www.ccin.com.cn/

- Engineering360 (Kaolin Product Specs): https://www.globalspec.com/learnmore/materials_chemicals_ceramics/ceramics/kaolin