Drilling operations require precision, efficiency, and reliability. One of the critical components in achieving these goals is the use of high-quality drilling fluids. Among the various materials used, drilling bentonite stands out for its unique properties. This article explores the Hezhen Drilling Briquettes—a product made from calcium-base and sodium-base bentonite—and its role in modern drilling practices. Developed by Hebei Hezhen Industry Co., Ltd., these briquettes offer a range of advantages that make them indispensable in the industry.

Understanding Bentonite and Its Role in Drilling

Bentonite is a naturally occurring clay mineral known for its ability to swell and form a viscous gel when hydrated. This property makes it an ideal component for drilling fluids, as it helps to stabilize the wellbore, seal off permeable formations, and carry cuttings to the surface. However, the traditional form of bentonite—loose powder—comes with several challenges, including dust exposure, spillage, and inconsistent performance. This is where drilling briquettes come into play.

Advantages of Drilling Briquettes Over Loose Bentonite

Drilling briquettes, made from compressed bentonite powder, offer several advantages over loose bentonite. They are easier to handle, transport, and store, reducing the risks associated with dust exposure and spillage. Additionally, briquettes provide a more consistent and predictable performance due to their uniform composition. For industries that require precision and safety, these benefits are invaluable.

According to the National Institute of Standards and Technology (NIST), the use of standardized materials in industrial applications ensures reliability and efficiency. While NIST does not specifically address bentonite in its publications, its emphasis on quality control and material standards aligns with the benefits of using briquettes in drilling operations.

Calcium-Base vs. Sodium-Base Bentonite: Key Differences

Calcium-base bentonite and sodium-base bentonite each have unique properties that make them suitable for different drilling conditions. Understanding these differences is crucial for selecting the right product for specific applications.

Calcium-Base Bentonite: High Gel Strength and Temperature Stability

Calcium-base bentonite is known for its high gel strength and temperature stability. These characteristics make it ideal for deeper and hotter wells, where traditional drilling fluids might degrade or lose effectiveness. The ability to maintain viscosity and structural integrity under extreme conditions ensures that the wellbore remains stable, reducing the risk of collapse or other complications.

For industries operating in high-temperature environments, such as geothermal drilling or deep oil and gas exploration, calcium-base bentonite briquettes are a preferred choice. Their resistance to thermal degradation ensures consistent performance, even in the most challenging conditions.

Sodium-Base Bentonite: Fluid Loss Control and Thixotropic Properties

On the other hand, sodium-base bentonite excels in fluid loss control and thixotropic properties. These properties are essential for maintaining wellbore stability in various drilling conditions. Sodium-base bentonite forms a thin, impermeable filter cake on the wellbore, minimizing the loss of drilling fluid into the surrounding formations. This not only improves drilling efficiency but also reduces environmental impact by preventing contamination of groundwater and soil.

Thixotropic properties allow the drilling fluid to become less viscous under shear stress (such as during pumping) and return to a more viscous state when at rest. This characteristic is particularly useful in maintaining the suspension of cuttings and ensuring even distribution of the fluid throughout the wellbore.

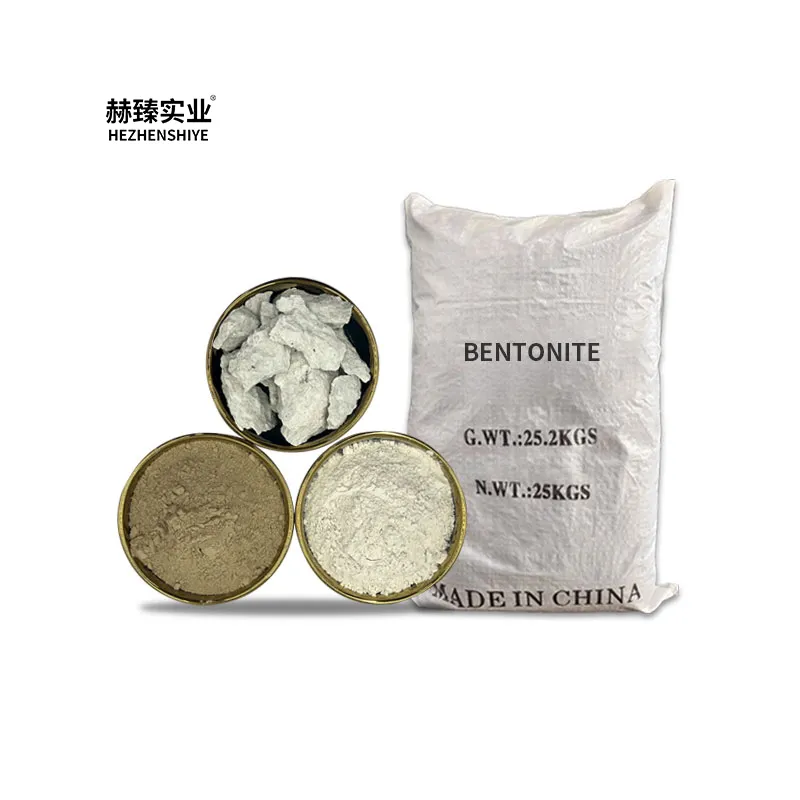

Product Specifications: A Detailed Overview

| Feature | Details |

|---|---|

| Place of Origin | China |

| Color | White/Yellow |

| Shape | Powder |

| Purity | 90-95% |

| Grade | Industrial Grade, Food Grade |

| Package | 25kg/bag, customized package |

| MOQ | 1kg |

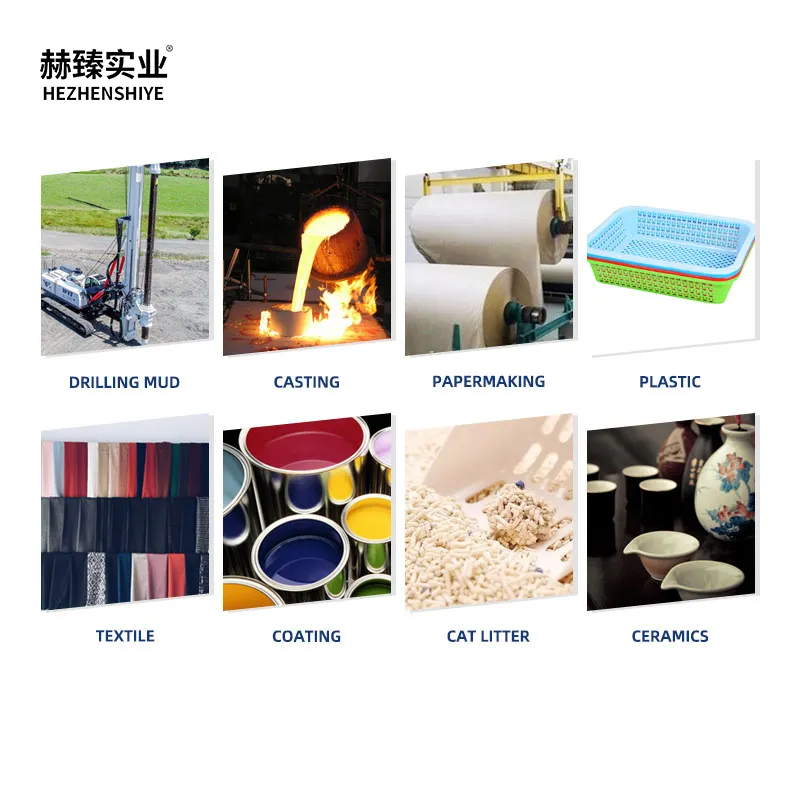

Applications of Hezhen Drilling Briquettes

The versatility of Hezhen Drilling Briquettes makes them suitable for a wide range of applications. From oil and gas exploration to construction and environmental projects, these briquettes play a critical role in ensuring the success of drilling operations.

Oil and Gas Industry

In the oil and gas industry, drilling fluids are essential for maintaining wellbore stability and facilitating the removal of cuttings. Calcium-base bentonite briquettes are particularly valuable in deep and high-temperature wells, where their thermal stability ensures consistent performance. Sodium-base bentonite briquettes, on the other hand, are ideal for applications requiring precise fluid loss control, such as in horizontal drilling or in formations with high permeability.

Construction and Infrastructure

Construction projects often require drilling for foundations, tunnels, and other underground structures. Hezhen Drilling Briquettes help stabilize the borehole, preventing collapse and ensuring the safety of workers and equipment. Their ease of handling and storage makes them a practical choice for construction sites, where space and safety are critical considerations.

Environmental and Remediation Projects

Environmental projects, such as groundwater remediation and soil stabilization, also benefit from the use of drilling bentonite. The ability of bentonite to form a barrier against fluid loss makes it an effective tool for containing contaminants and preventing further pollution. Sodium-base bentonite briquettes are particularly useful in these applications due to their thixotropic properties, which help maintain the integrity of the barrier over time.

About Hebei Hezhen Industry Co., Ltd.

Hebei Hezhen Industry Co., Ltd. is a leading manufacturer and supplier of high-quality drilling materials, including drilling bentonite and bentonite drilling mud. With a commitment to innovation and excellence, the company has established itself as a trusted partner in the drilling industry. Their products are designed to meet the highest standards of performance and reliability, ensuring that customers can achieve their objectives efficiently and safely.

As highlighted by NIST, the importance of quality control in industrial materials cannot be overstated. Hebei Hezhen Industry Co., Ltd. adheres to strict quality assurance protocols, ensuring that their products meet the rigorous demands of modern drilling operations. This commitment to quality is reflected in the company's reputation and the satisfaction of its customers.

Conclusion

Hezhen Drilling Briquettes—made from calcium-base and sodium-base bentonite—are essential components in modern drilling operations. Their unique properties, combined with the advantages of being in a briquette form, make them a reliable choice for a wide range of applications. Whether in the oil and gas industry, construction, or environmental projects, these briquettes offer the performance, safety, and efficiency needed to ensure the success of drilling operations.

For more information about Hezhen Drilling Briquettes and other products from Hebei Hezhen Industry Co., Ltd., visit their official website here.

References

National Institute of Standards and Technology (NIST). (n.d.). Retrieved from https://www.nist.gov/