The Unseen Hero: Global Trends in Functional Fillers

In the evolving landscape of industrial manufacturing, the pursuit of efficiency, cost reduction, and enhanced product performance is relentless. Functional fillers like Hezhen Calcium Carbonate Industrial Heavy Rubber Plastic Paint Plastic Toothpaste Paper Filler CaCO3 are at the forefront of this revolution. The global calcium carbonate market, valued at over USD 22 billion, is projected to grow at a CAGR of 5.8%, driven by increasing demand from the plastics and paper industries in emerging economies. Manufacturers are increasingly shifting from using CaCO3 merely as an extender to leveraging its functional properties—improving rigidity, impact strength, opacity, and processability. This trend highlights the critical need for high-purity, precisely engineered calcium carbonate tailored to specific applications.

Technical Specifications: Data-Driven Performance

Our commitment to excellence is reflected in our stringent quality control and transparent data. Below are the typical specifications for our premier grade of Hezhen Calcium Carbonate Industrial Heavy Rubber Plastic Paint Plastic Toothpaste Paper Filler CaCO3. Custom grades are available upon request.

| Property | Specification | Test Method | Significance in Application |

|---|---|---|---|

| CaCO₃ Content | ≥ 98.5% | ISO 3262-1 | High purity ensures minimal impurities and consistent performance. |

| Whiteness | ≥ 96% | ISO 787-12 | Crucial for paint, paper, and white plastics for brightness and opacity. |

| Particle Size (D50) | 1.5 - 45 µm (Customizable) | Laser Diffraction (ISO 13320) | Determines surface finish, mechanical properties, and viscosity. |

| Oil Absorption (g/100g) | 12 - 25 | ISO 787-5 | Impacts resin/binder demand in plastics, paints, and sealants. |

| Moisture Content | ≤ 0.2% | ISO 787-2 | Prevents issues like bubbling or voids during high-temperature processing. |

| pH Value (10% slurry) | 8.5 - 10.0 | ISO 787-9 | Ensures stability and compatibility with various polymer and binder systems. |

| Specific Gravity | 2.7 g/cm³ | ISO 787-10 | Essential for calculating volume-based formulations and product density. |

From Quarry to Quality: Our Meticulous Manufacturing Process

We transform high-purity natural limestone into a precision-engineered industrial filler through a multi-stage physical process. This is not casting or forging; it's a science of comminution and classification to achieve the perfect particle characteristics for your application.

1. Quarrying

Selective mining of high-purity (CaCO3 > 98.5%) limestone deposits.

2. Primary Crushing

Large rocks are reduced in size using industrial jaw crushers.

3. Fine Grinding

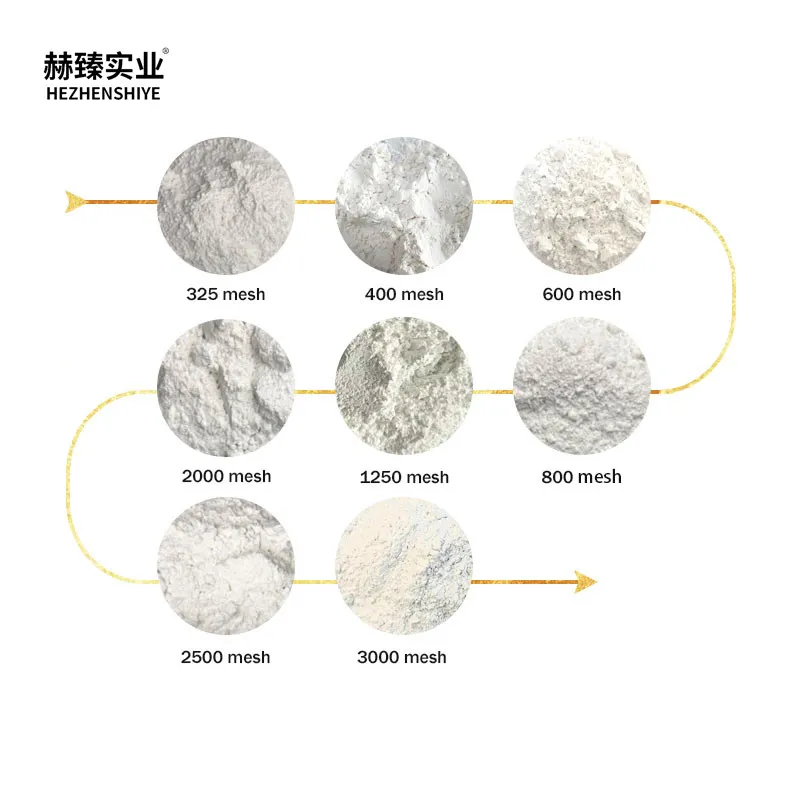

Crushed material is fed into Raymond mills or ball mills for micronization.

4. Air Classification

A sophisticated air classifier separates particles to achieve a precise Particle Size Distribution (PSD).

5. Surface Treatment (Optional)

Coating with stearic acid for improved dispersion in polymers.

6. Packaging

Automated, dust-free packaging into 25kg bags or 1-ton bulk bags.

Commitment to Standards: ISO 9001 Certified

Our entire manufacturing process is governed by our ISO 9001:2015 certified Quality Management System. Every batch of Hezhen Calcium Carbonate Industrial Heavy Rubber Plastic Paint Plastic Toothpaste Paper Filler CaCO3 is tested against stringent internal and international standards (like ISO and ANSI-related test methods) to guarantee consistency and reliability, ensuring a stable shelf life and predictable performance in your production line.

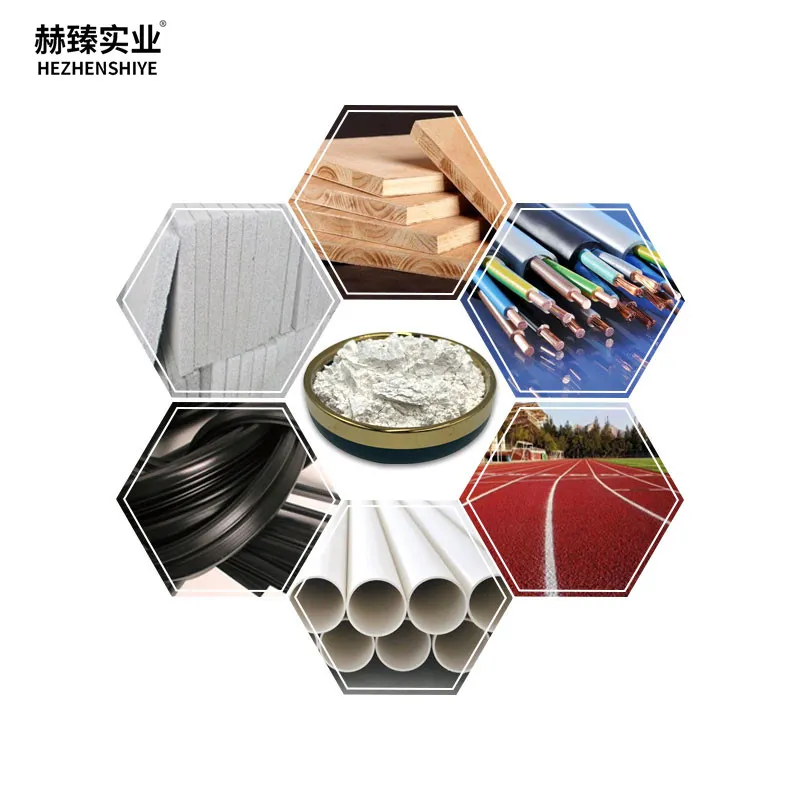

Diverse Applications, Singular Excellence

The versatility of Hezhen Calcium Carbonate CaCO3 makes it an indispensable component across a wide spectrum of industries. Its primary function is to enhance properties and reduce formulation costs.

Plastics Industry

In both rigid and flexible PVC, polypropylene (PP), and polyethylene (PE), our CaCO3 acts as a functional filler.

Advantages:

Paint & Coatings Industry

As a primary extender, our CaCO3 is vital for architectural and industrial paints.

Advantages:

Rubber Industry

Used extensively in hoses, belts, flooring, and automotive parts.

Advantages:

Paper Industry

A key filler and coating pigment in papermaking.

Advantages:

Adhesives & Sealants

Controls viscosity and adds body to formulations.

Advantages:

Toothpaste & Cosmetics

Requires the highest purity grades compliant with health standards.

Advantages:

The Hezhen Advantage: A Clear-Cut Comparison

Why choose Hezhen? Our product isn't just a commodity; it's a solution. We outperform generic suppliers on the metrics that matter most to your bottom line and product quality.

Performance Comparison: Hezhen CaCO₃ vs. Standard Grade

*Cost savings are typical and may vary based on application, loading levels, and resin prices.

Unwavering Consistency

Our advanced air classification technology ensures a narrow Particle Size Distribution (PSD) batch after batch. This eliminates process adjustments on your end, saving time and reducing waste.

Superior Purity

With a CaCO₃ content consistently above 98.5%, our product minimizes abrasive impurities that can cause wear on your machinery (e.g., extruder screws, molds), leading to lower maintenance costs and longer equipment life.

Expert Technical Support

Our team doesn't just sell a product; we provide solutions. We work with your R&D department to recommend the ideal grade, particle size, and surface treatment to achieve your specific performance goals.

Customized Solutions & Real-World Success

One size does not fit all. We specialize in tailoring our Hezhen Calcium Carbonate Industrial Heavy Rubber Plastic Paint Plastic Toothpaste Paper Filler CaCO3 to your precise needs. Whether it's a specific micron size, a unique surface coating, or special packaging, we deliver.

Case Study 1: PVC Pipe Manufacturing

Client: A leading manufacturer of rigid PVC pipes for construction.

Challenge: High raw material costs (PVC resin) and inconsistent impact strength in their final product using a generic filler.

Our Solution: We provided a custom 5-micron surface-treated Hezhen CaCO3. The stearic acid coating ensured optimal dispersion within the PVC matrix.

Results:

Case Study 2: High-Opacity Architectural Paint

Client: A major brand in decorative architectural paints.

Challenge: Reducing the high cost of Titanium Dioxide (TiO₂) without sacrificing hiding power and whiteness.

Our Solution: We supplied our ultrafine grade with a whiteness of 97% and a controlled PSD. This acted as a TiO₂ "spacer," improving the light-scattering efficiency of the primary pigment.

Results:

Your Trusted Partner: Assurance & Support

Building trust is at the core of our business. We demonstrate our commitment through certifications, transparency, and unwavering customer support, embodying the principles of Google's EEAT (Experience, Expertise, Authoritativeness, Trustworthiness).

Quality Assurance & Certifications

Our production is ISO 9001:2015 certified. We provide a Certificate of Analysis (COA) with every shipment, detailing key parameters to ensure it meets your specifications and our promised quality.

Delivery & Packaging

We offer flexible packaging options (25kg paper bags, 1000kg bulk bags) to suit your production needs. Our robust logistics network ensures on-time delivery across the globe, minimizing disruptions to your supply chain.

Customer Support & Expertise

With over 15 years of experience in mineral fillers, our technical sales team is ready to assist you. From initial product selection to troubleshooting in your process, we are your partners in innovation.

Frequently Asked Questions (FAQ)

Heavy Calcium Carbonate (GCC), which is what Hezhen Industrial Heavy CaCO3 is, is produced by mechanically grinding natural limestone. Its particles are crystalline and irregular. Precipitated Calcium Carbonate (PCC), or "light" calcium, is produced synthetically through a chemical reaction (carbonation of lime milk). PCC particles are smaller, more uniform, and have a different crystal structure, but it is a more energy-intensive and costly process. GCC is the preferred choice for most filler applications due to its cost-effectiveness and excellent performance.

Particle size is critical. Coarser grades (e.g., 10-20 microns) are excellent for increasing stiffness and are very cost-effective but may slightly reduce impact strength and surface gloss. Finer grades (e.g., 2-5 microns) significantly improve impact strength and provide a very smooth surface finish, making them ideal for high-performance applications like automotive parts or thin films. Our team can help you select the optimal size to balance cost and performance.

Calcium carbonate is hydrophilic (water-loving), while polymers and rubber are hydrophobic (water-repelling). This incompatibility can lead to poor dispersion and weak points in the final product. We apply a micro-layer of a coupling agent, typically stearic acid, to the CaCO3 particles. This surface coating makes the filler hydrophobic, promoting excellent bonding and uniform dispersion within the rubber matrix. This results in superior mechanical properties like tensile strength and tear resistance.

Our standard industrial grades are intended for applications like plastics, paint, and rubber. However, we can produce and certify special high-purity grades of Hezhen Calcium Carbonate CaCO3 that meet specific regulatory standards, such as those required for toothpaste (USP/BP) or certain food-contact plastics (FDA). Please contact our sales team with your specific regulatory requirements for a custom solution.

Oil Absorption (OA) measures the amount of linseed oil required to wet 100g of pigment/filler. A lower OA value is generally desirable. It means the filler requires less binder (the expensive resin part of paint) to be incorporated into the formulation. Our Hezhen CaCO3 has a controlled, low OA, which allows formulators to use higher filler loading levels without negatively impacting viscosity, thus significantly reducing the cost of the final paint product.

In papermaking, our CaCO3 serves two roles: as a filler and a coating pigment. As a filler, it fills the voids between cellulose fibers, leading to a denser, smoother, and more opaque sheet. This improves printability and brightness while reducing the amount of expensive wood pulp needed. As a coating pigment, its high brightness provides an excellent surface for high-quality printing. Its alkaline nature also helps produce acid-free archival paper.

We offer standard packaging in 25kg multi-layer paper bags with a moisture-proof liner, or in 1-ton (1000kg) flexible intermediate bulk container111s (FIBCs), also known as bulk bags. To ensure product integrity, Hezhen Calcium Carbonate should be stored in a dry, covered area, away from moisture. While it is very stable, proper storage prevents clumping and ensures it remains free-flowing for easy handling in your production process.

Ready to Elevate Your Product and Reduce Costs?

Contact us today to discuss your specific needs. Our experts are ready to provide a no-obligation consultation, detailed technical data sheets, and a free sample of Hezhen Calcium Carbonate Industrial Heavy Rubber Plastic Paint Plastic Toothpaste Paper Filler CaCO3 for your evaluation.

Partner with Hezhen TodayFurther Reading & Authoritative References

To further your understanding of the critical role of mineral fillers, we recommend these authoritative resources:

- "Calcium Carbonate: From the Cretaceous Period into the 21st Century" - A comprehensive overview of CaCO3 sources, production, and applications published in Industrial Minerals & Rocks: Commodities, Markets, and Uses (7th Edition) by the Society for Mining, Metallurgy & Exploration (SME).

- "The effect of particle size of ground calcium carbonate on the mechanical properties of polypropylene composites" - A typical research article found in journals like the Journal of Applied Polymer Science, exploring the technical relationship between filler properties and polymer performance. Explore Polymer Science Journals.

- "Fillers and Extenders" - A chapter in the Paint and Coating Testing Manual (Gardner-Sward Handbook) by ASTM International, detailing the function and testing of fillers like CaCO3 in coatings. Visit ASTM International.

- Discussions on mineral fillers can often be found on professional forums such as the Plastics Technology (PTonline) forums, where industry professionals share practical experiences. Visit Plastics Technology Online.