Sodium Montmorillonite in Concrete Coatings: Insider Notes from the Field

I’ve been tracking mineral fillers in coating lines for years, and one product keeps popping up in specs and shop-floor chatter: Hezhen Sodium montmorillonite powder for feed filling of concrete coating. Originating from No. 8 Xisha East Road, Shikan Village, Ciyu Town, Lingshou County, Shijiazhuang City, Hebei Province, it’s a deceptively simple clay mineral with outsized effects on durability and barrier performance.

Why the buzz? Industry trends

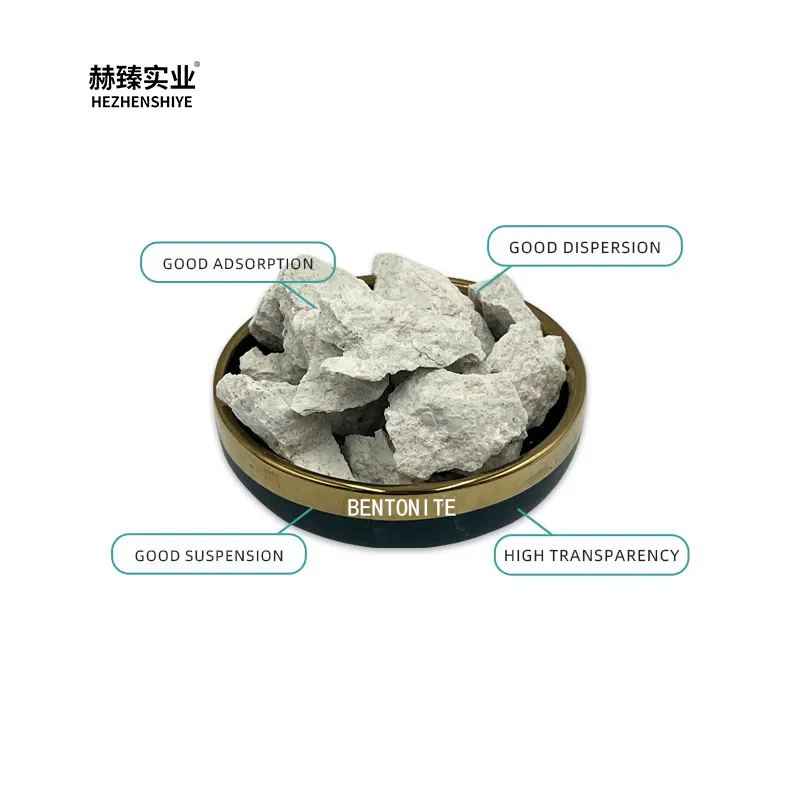

Coatings are shifting toward mineral-rich systems with better thixotropy and lower VOCs. Sodium montmorillonite (Na-MMT) delivers plate-like particles that create a tortuous path for water and chlorides—great for coastal jobs and de-icing salts. Many customers say it “tightens the film” without killing workability. And, to be honest, it’s surprisingly cost-effective compared with some fancy nano-additives.

Key specifications (typical, ≈ values)

| Mineral type | Sodium montmorillonite (Na-bentonite) |

| CEC | ≈ 80–110 meq/100 g |

| Specific surface area | ≈ 600–800 m²/g |

| Swelling index | ≈ 24–30 mL/2 g |

| D50 particle size | ≈ 8–18 μm (customizable) |

| Moisture | ≤ 12% (real-world may vary) |

| pH (2% slurry) | ≈ 8.5–10.0 |

| Recommended dosage | ≈ 2–8% of binder in coating feed |

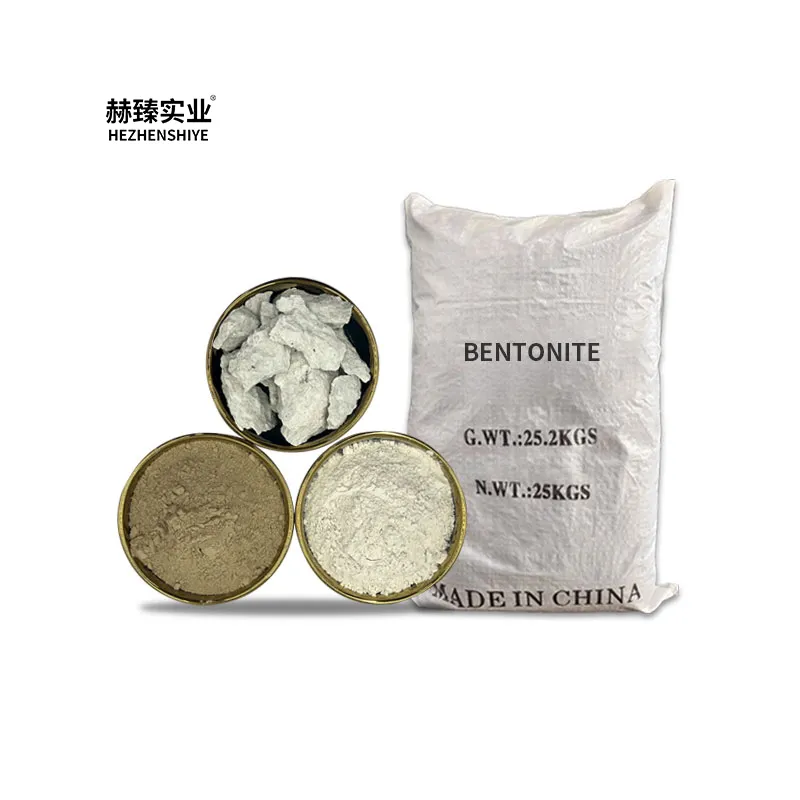

| Packaging | 25 kg bags / jumbo bags |

Advantages users report

- Rheology control and sag resistance; smoother roll/ spray feel.

- Barrier effect: reduced chloride ingress and water uptake.

- Crack resistance via micro-filling and shrinkage moderation.

- Better film density without excessive resin demand.

- Service life bump (I’ve seen ≈ 15–25% in aggressive exposure, test-dependent).

Process flow and testing

- Materials: binder (acrylic/epoxy/polymer-modified cement), pigments, Hezhen Sodium montmorillonite powder for feed filling of concrete coating, dispersant, defoamer.

- Method: pre-wet Na-MMT in water (≈ 2–5% solids), high-shear disperse 10–20 min; add to mill-base; adjust viscosity.

- Quality checks: ASTM C1585 (capillary absorption), ASTM C642 (density/absorption), ASTM C1202 (RCPT), EN 1504-2 film tests; GB 8076 for admixture conformity.

- Service life estimation: chloride profiles + freeze–thaw cycles (where relevant).

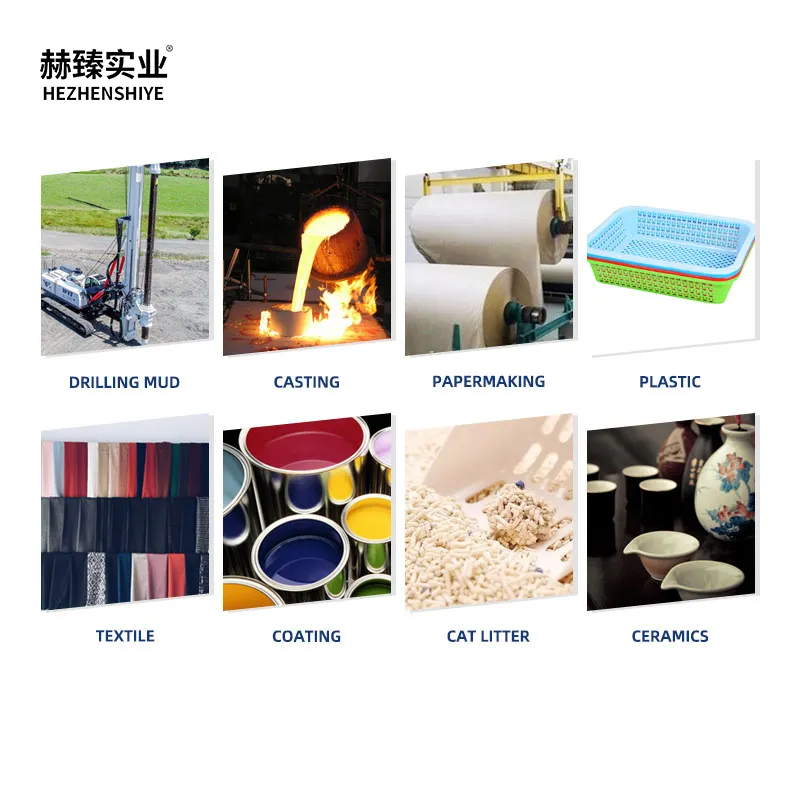

- Industries: transport infrastructure, parking decks, water tanks, industrial floors, marine structures.

Application scenarios

Coastal bridges, splash-zone piers, warehouse floors taking forklift abuse, potable water tanks (verify coating system certification), rooftops with ponding risks—these are classic fits for Hezhen Sodium montmorillonite powder for feed filling of concrete coating. Actually, it shines wherever you need a denser, more forgiving coating film.

Case notes (field + lab)

- Harbor apron, chloride exposure: RCPT at 28 d dropped from ≈ 2800 to ≈ 1700 coulombs; C1585 absorption reduced ≈ 35% vs. control; no adverse impact on gloss/adhesion.

- Logistics warehouse in Hebei: abrasion loss down ≈ 20%; applicators liked the “creamy” roll-out and lower sag at 250–300 μm WFT.

Vendor comparison (indicative)

| Vendor | Customization | Certifications | Lead time | Traceability |

|---|---|---|---|---|

| Hezhen (Hebei) | D50, moisture, pregel options | ISO 9001/14001, MSDS | ≈ 7–15 days | Mine-to-bag records |

| Importer A | Limited grades | ISO 9001 | ≈ 20–30 days | Batch-level only |

| Local reseller B | Ad-hoc | Varies | Stock-dependent | Limited |

Customization & feedback

Hezhen supports grade tailoring (D50, moisture, pre-activated slurries). Several coaters told me they hit target viscosity faster, with fewer dispersant tweaks. If you scale up, ask for a retained sample protocol and COA alignment with your ASTM/EN test plan—saves headaches later.

Bottom line: if you want a practical barrier boost and friendlier application behavior, Hezhen Sodium montmorillonite powder for feed filling of concrete coating is worth a lab panel—and a weekend field mock-up, I guess.

References

- ASTM C1585 – Standard Test Method for Measurement of Rate of Absorption of Water by Hydraulic-Cement Concretes.

- ASTM C1202 – Standard Test Method for Electrical Indication of Concrete’s Ability to Resist Chloride Ion Penetration.

- EN 1504-2 – Products and systems for the protection and repair of concrete structures: Surface protection systems.

- ACI 212.3R-16 – Report on Chemical Admixtures for Concrete.

- GB 8076 – Concrete Admixtures (China National Standard).