Introduction to Hezhen Yellow white bentonite

In the demanding sectors of oil and gas drilling, civil engineering, and specialized industrial coatings, the rheological properties and stability of fluid systems are paramount. Hezhen Shiye proudly presents Hezhen Yellow white bentonite, a high-performance, nano-calcium-based bentonite meticulously engineered to deliver superior results in high-viscosity applications. This advanced mineral product is specifically formulated for optimizing mud drilling and enhancing the characteristics of industrial paints, offering unparalleled suspension, fluid loss control, and thixotropic properties. Its unique composition and sophisticated processing set a new benchmark for efficiency and reliability in mission-critical operations.

This article delves into the technical intricacies, application advantages, and comprehensive value proposition of Hezhen Yellow white bentonite, providing essential insights for B2B decision-makers, engineers, and procurement professionals seeking to elevate their operational standards and product performance. We will explore its manufacturing precision, adherence to stringent industry standards, and a spectrum of applications that underscore its versatility and robustness.

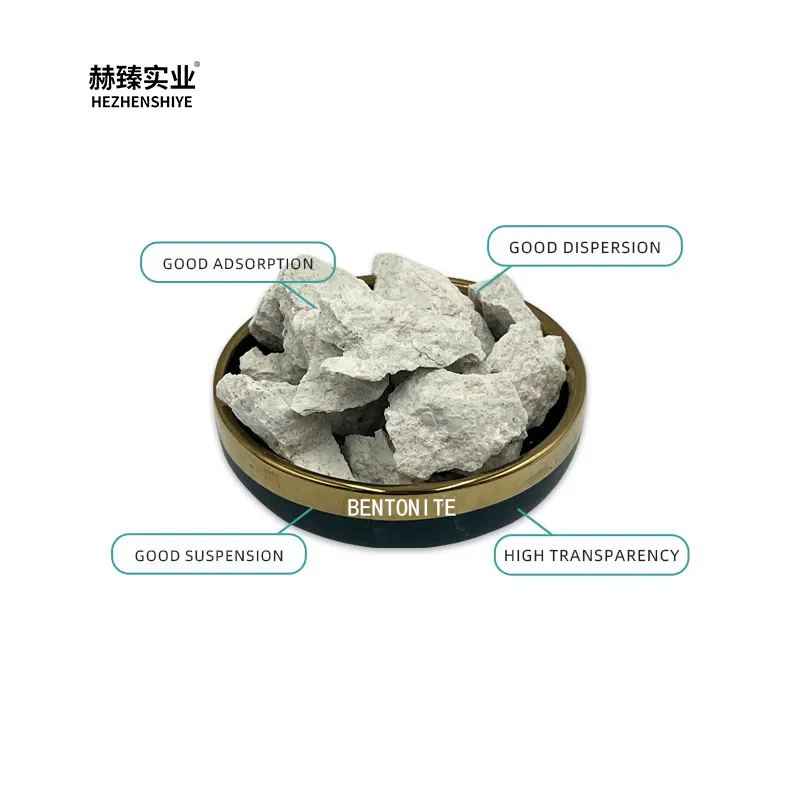

Figure 1: High-purity Hezhen Yellow white bentonite raw material.

Industry Trends in Advanced Bentonite Applications

The global demand for high-performance drilling fluids and specialized industrial coatings continues its upward trajectory, driven by complex exploration environments, stringent environmental regulations, and the need for enhanced material properties. In the oil and gas sector, unconventional drilling techniques, deepwater exploration, and horizontal drilling necessitate drilling muds with superior rheological stability, exceptional fluid loss control, and robust shale inhibition. Standard bentonite often falls short in these extreme conditions, paving the way for advanced, engineered bentonite solutions.

Similarly, the paints and coatings industry is experiencing a shift towards formulations that offer improved shelf stability, anti-sag properties, enhanced pigment suspension, and controlled rheology for diverse application methods. Nano-calcium-based bentonites, such as Hezhen Yellow white bentonite, are at the forefront of this innovation, providing the necessary thixotropic and thickening capabilities without compromising other critical paint characteristics. The emphasis is increasingly on sustainable, high-efficiency additives that reduce material consumption and extend product service life. Market analyses project significant growth in the bentonite market, particularly for specialized and chemically modified variants, reflecting an industry-wide commitment to performance optimization and cost-effectiveness.

Manufacturing Process Flow of Hezhen Yellow white bentonite

The production of Hezhen Yellow white bentonite is a sophisticated, multi-stage process designed to unlock the optimal performance characteristics of its high-purity calcium bentonite source. This involves careful material selection, advanced processing techniques, and rigorous quality control to ensure consistency and superior functionality.

1. Raw Material Sourcing & Pre-treatment

High-grade calcium bentonite is meticulously selected from Hezhen’s proprietary mines, characterized by its low impurity content and high montmorillonite percentage. Initial crushing reduces the raw ore to manageable sizes, followed by mechanical sorting to remove large non-bentonite minerals.

2. Grinding & Micronization

The pre-treated material undergoes a multi-stage grinding process, progressively reducing particle size. This includes fine grinding and micronization techniques, achieving the desired particle distribution essential for the nano-calcium-based structure, which enhances surface area and reactivity.

3. Sodium Activation (Ion Exchange)

The core of developing the high-viscosity profile lies in a controlled sodium activation process. Calcium ions (Ca²⁺) in the bentonite interlayers are exchanged with sodium ions (Na⁺) through a proprietary wet beneficiation method. This transforms the calcium bentonite into a sodium-activated form, significantly increasing its swelling capacity and rheological performance.

4. Drying & Milling

Activated bentonite slurry is dewatered and then carefully dried using advanced low-temperature drying technology to preserve the activated structure. The dried material is then milled to a precise particle size distribution, optimizing it for both drilling mud and paint applications.

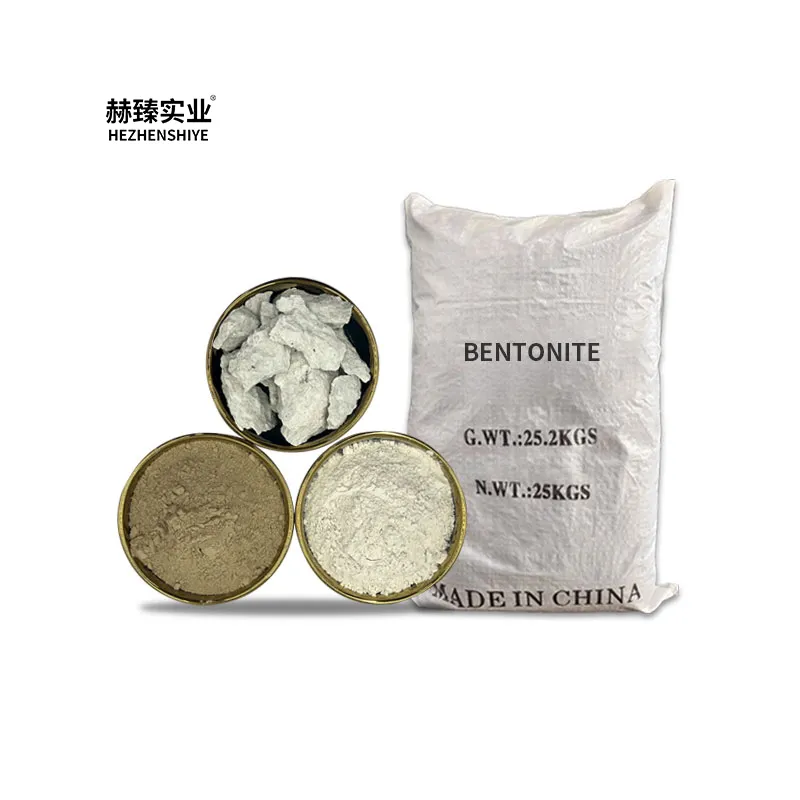

5. Quality Control & Packaging

Throughout the entire process, extensive quality control checks are performed, adhering to international standards such as ISO 9001 and API 13A for drilling fluids. Key parameters like viscosity, fluid loss, swelling index, and montmorillonite content are rigorously tested. The final product is then packaged in moisture-resistant bags, ready for distribution.

This meticulous process ensures that Hezhen Yellow white bentonite consistently meets the stringent requirements for high viscosity, superior suspension, and rheological stability demanded by target industries such as petrochemical, metallurgy, and water supply & drainage. The emphasis on nano-scale activation yields a product with enhanced surface area and improved interaction with fluid systems, demonstrating advantages in typical application scenarios such as energy saving through optimized drilling fluid performance and improved corrosion resistance in coatings due to better pigment dispersion.

Figure 2: Advanced processing facilities for Hezhen Yellow white bentonite.

Technical Specifications of Hezhen Yellow white bentonite

Hezhen Yellow white bentonite is characterized by a precise set of technical parameters that define its high-performance profile. These specifications are crucial for engineers in formulating drilling muds and paints to achieve desired rheological and stability objectives.

These parameters highlight the superior quality of Hezhen Yellow white bentonite, particularly its high viscosity and low fluid loss, which are critical for maintaining wellbore stability and efficient drilling operations. The high montmorillonite content and CEC further underscore its effectiveness as a rheological modifier and suspending agent.

Figure 3: Quality control and testing for Hezhen Yellow white bentonite.

Application Scenarios

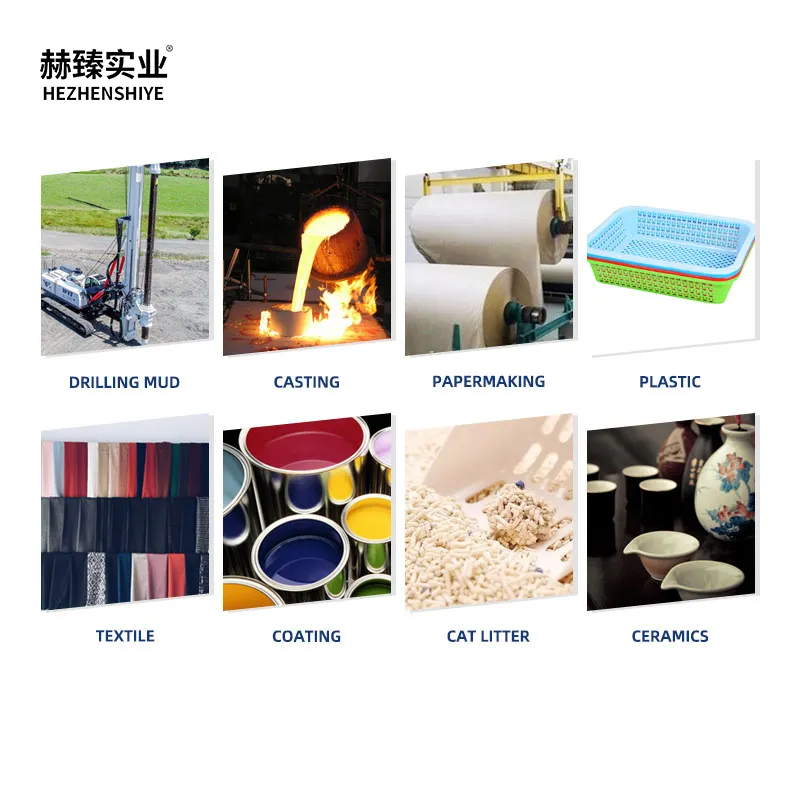

The versatility and high-performance characteristics of Hezhen Yellow white bentonite make it an indispensable additive across a multitude of industrial applications where rheological control, suspension, and filtration are critical.

- Oil & Gas Drilling Mud: As a primary component in water-based drilling fluids, Hezhen Yellow white bentonite provides exceptional viscosity, gel strength, and filtration control. It effectively suspends drill cuttings, lubricates the drill bit, and stabilizes the wellbore, especially in challenging formations and high-temperature, high-pressure (HTHP) environments. Its nano-calcium-based structure ensures minimal fluid loss, preventing formation damage and enhancing drilling efficiency.

- Horizontal Directional Drilling (HDD) and Piling: In trenchless technology and foundation construction, this bentonite forms stable slurries that prevent borehole collapse, facilitate spoil removal, and reduce friction for pipe pulling. Its high yield point and thixotropic properties are crucial for maintaining bore integrity during pauses in operation.

- Industrial Paints & Coatings: As a rheology modifier and suspending agent, it improves the anti-settling properties of pigments, prevents sagging on vertical surfaces, and enhances brushability or sprayability. The fine particle size contributes to smoother film formation and better mechanical properties of the cured coating. It's particularly effective in water-based paints, primers, and protective coatings.

- Ceramics: Used as a plasticizer and binder, improving the plasticity of ceramic bodies, green strength, and reducing cracking during drying and firing.

- Foundry Sand Binders: Provides excellent bonding strength and plasticity to foundry sands, producing high-quality molds with improved surface finish and dimensional accuracy for metal casting.

- Water & Wastewater Treatment: Acts as an effective flocculant and adsorbent for clarifying water and removing heavy metals and organic pollutants.

Figure 4: Application in drilling muds requiring high viscosity.

Technical Advantages of Hezhen Yellow white bentonite

The advanced formulation and processing of Hezhen Yellow white bentonite confer several distinct technical advantages that set it apart from conventional bentonites and other rheological additives.

- Superior High Viscosity & Thixotropy: The nano-calcium-based activation process creates an intricate lamellar structure that readily hydrates and disperses, generating a high-viscosity fluid with excellent shear-thinning (thixotropic) properties. This ensures efficient suspension of solids, such as drill cuttings or pigment particles, at rest, while reducing pumping resistance during flow.

- Exceptional Fluid Loss Control: The fine particle size and high swelling capacity of Hezhen Yellow white bentonite enable it to form a thin, impermeable filter cake on borehole walls or substrate surfaces. This minimizes fluid invasion into porous formations in drilling, preventing formation damage and ensuring better control over paint film properties.

- Enhanced Wellbore Stability: By forming a robust filter cake and providing adequate hydrostatic pressure, the bentonite aids in preventing wellbore collapse and shale hydration, crucial for maintaining drilling integrity, especially in challenging geological conditions.

- Broad pH Tolerance & Chemical Stability: Engineered to perform across a wide range of pH conditions, Hezhen Yellow white bentonite maintains its rheological properties and stability even in the presence of various contaminants or chemical additives commonly found in drilling fluids and paint formulations.

- Cost-Effectiveness & Reduced Environmental Impact: Its high efficiency means lower dosage rates are required to achieve desired performance, leading to reduced material consumption and lower transportation costs. As a naturally occurring mineral, its environmental footprint is also significantly smaller compared to many synthetic alternatives.

- Improved Suspending Power: In paints, it prevents hard settling of pigments and fillers, extending shelf life and ensuring consistent color and performance upon application. In drilling, it effectively carries cuttings out of the hole.

Figure 5: Performance testing for Hezhen Yellow white bentonite rheology.

Vendor Comparison: Hezhen Yellow white bentonite vs. Alternatives

Choosing the right bentonite product is a critical decision impacting operational efficiency and final product quality. A comparison of Hezhen Yellow white bentonite against typical industry alternatives highlights its unique value proposition.

This comparison clearly illustrates that while standard bentonites offer a baseline, Hezhen Yellow white bentonite provides a significantly enhanced performance envelope, particularly in terms of viscosity development, fluid loss control, and thermal stability. Polymer-based additives can offer specific advantages but often come with higher costs and may require more complex formulation strategies. For demanding applications, the overall value and consistent performance of Hezhen Yellow white bentonite make it the preferred choice.

Customized Solutions and Technical Support

Hezhen Shiye understands that every industrial application presents unique challenges and requirements. Leveraging decades of experience in mineral processing and rheology, we offer tailored solutions to optimize the performance of Hezhen Yellow white bentonite for specific client needs.

- Formulation Optimization: Our team of geologists and chemical engineers works closely with clients to fine-tune bentonite formulations, adjusting parameters such as particle size distribution, activation level, and additive compatibility to meet precise viscosity, fluid loss, and thixotropy targets for drilling muds or paint systems.

- On-Site Technical Assistance: For complex projects, Hezhen Shiye provides on-site technical support, assisting with product integration, performance monitoring, and troubleshooting to ensure optimal application and efficiency.

- R&D Collaboration: We engage in collaborative research and development with partners to innovate new bentonite products or modify existing ones to address emerging industry trends and specific performance gaps. This includes specialized products for extreme temperature or salinity environments.

- Comprehensive Testing & Analysis: Utilizing state-of-the-art laboratories, we offer detailed analysis of bentonite performance in client-specific matrices, including rheological profiling, filtration tests, and long-term stability assessments.

Our commitment to partnership ensures that clients receive not just a product, but a complete solution backed by expert knowledge and dedicated support.

Figure 6: R&D and client collaboration on tailored bentonite solutions.

Application Case Studies

The proven performance of Hezhen Yellow white bentonite is best illustrated through real-world applications where it has delivered significant operational benefits.

Case Study 1: Deep Vertical Oil & Gas Well Drilling

A major E&P company was drilling a deep vertical well (5,000m+) in a challenging formation characterized by reactive shales and high formation pressures. Their existing bentonite mud system struggled with maintaining adequate viscosity and experienced significant fluid loss, leading to frequent wellbore instability issues and increased non-productive time (NPT).

Hezhen Shiye recommended integrating Hezhen Yellow white bentonite into their mud formulation. Post-implementation, the drilling fluid exhibited significantly improved rheological properties:

- Viscosity (600 RPM): Increased by 25% at a lower bentonite concentration, indicating superior yield per unit.

- API Fluid Loss: Reduced by 35%, leading to a thinner, more stable filter cake and better wellbore integrity.

- Gel Strength: Achieved stable 10-minute gel strengths, preventing cuttings settlement during static periods.

These improvements resulted in a 15% reduction in drilling time due to fewer wellbore issues and a 10% saving in overall drilling fluid costs. The client reported enhanced operational confidence and expressed satisfaction with the product's performance.

Case Study 2: High-Performance Industrial Paint Formulation

A leading industrial coatings manufacturer sought to develop a new line of high-build protective coatings with improved anti-sag properties and pigment suspension for demanding applications in marine and heavy machinery sectors. Their existing rheological additives caused issues with film leveling and required higher dosage, impacting cost and formulation complexity.

Hezhen Shiye collaborated with the manufacturer, providing samples of Hezhen Yellow white bentonite for rigorous testing. The results were conclusive:

- Anti-Sag Index: Improved by 40% compared to previous formulations, allowing for thicker, single-coat applications.

- Pigment Settling: Eliminated hard settling of heavy pigments even after 12 months of storage, extending shelf life.

- Application Rheology: Demonstrated optimal shear-thinning for spray application while quickly building viscosity post-spray, preventing drips and runs.

The manufacturer successfully launched their new product line, attributing a significant portion of its performance advantages and market success to the consistent and superior rheological control provided by Hezhen Yellow white bentonite.

Figure 7: Final product packaging ready for global distribution.

Frequently Asked Questions (FAQ)

Q1: What makes Hezhen Yellow white bentonite 'nano-calcium-based'?

A1: While the raw material is calcium bentonite, our proprietary activation process involves a controlled ion exchange where calcium ions are partially replaced by sodium ions. The "nano-calcium-based" nomenclature highlights that this conversion is optimized at a nano-scale level, enhancing the surface area and reactivity of the montmorillonite layers. This sophisticated treatment is what enables its high viscosity and superior performance in applications typically requiring sodium bentonite, making it an advanced, engineered calcium bentonite.

Q2: Is Hezhen Yellow white bentonite suitable for both water-based drilling muds and paints?

A2: Absolutely. Its high swelling capacity, excellent thixotropic properties, and fine particle size distribution make it ideal for both applications. In drilling, it provides superior suspension and fluid loss control. In paints, it acts as an effective rheology modifier, preventing pigment settling and improving anti-sag properties, particularly in water-based systems.

Q3: What are the typical lead times for large orders?

A3: For standard product volumes, our typical lead time is 2-4 weeks from order confirmation, depending on destination and logistical requirements. For customized formulations or exceptionally large orders, lead times may extend to 4-6 weeks. We maintain strategic stock levels and operate efficient production lines to ensure timely delivery. We recommend discussing your specific volume and timeline needs with our sales team for precise scheduling.

Q4: What kind of warranty or quality assurance does Hezhen Shiye offer?

A4: Hezhen Shiye adheres to stringent quality control standards, including ISO 9001 certification and compliance with relevant API 13A specifications for drilling mud applications. Our products come with a guarantee of meeting published technical specifications. Any deviation from these specifications will be addressed promptly, including replacement or credit for defective product. We stand by the quality and consistency of Hezhen Yellow white bentonite.

Q5: How do I get technical support or discuss a customized solution?

A5: Our dedicated technical support team is available via phone, email, or through our website contact form. For in-depth discussions on customized solutions, we encourage you to schedule a consultation with our R&D specialists. We are committed to providing comprehensive support to ensure optimal product performance for your unique applications.

Conclusion

Hezhen Yellow white bentonite stands as a testament to Hezhen Shiye’s commitment to innovation and excellence in mineral processing. As a high-viscosity, nano-calcium-based bentonite, it provides an advanced solution for the complex demands of mud drilling and specialized paint formulations. Its meticulously controlled manufacturing process, adherence to rigorous quality standards, and verifiable technical advantages translate into tangible benefits for our clients: enhanced operational efficiency, superior product performance, and significant cost savings.

For B2B partners seeking reliability, advanced rheological control, and a proven track record, Hezhen Yellow white bentonite represents an optimal choice. We invite you to contact Hezhen Shiye to discuss how our advanced bentonite solutions can be tailored to elevate your specific industrial applications.

References

- API Recommended Practice 13B-1: Standard Procedure for Field Testing Water-Based Drilling Fluids. American Petroleum Institute.

- ASTM E946: Standard Test Method for Bentonite Swell Index. ASTM International.

- Murray, H.H. (2007). Applied Clay Mineralogy: Occurrences, Processing and Applications. Elsevier Science.

- Caenn, R., Darley, H.C.H., & Gray, G.R. (2016). Composition and Properties of Drilling and Completion Fluids. Gulf Professional Publishing.

- Bergaya, F., & Lagaly, G. (Eds.). (2006). Handbook of Clay Science. Elsevier Science.