Filler tourmaline powder plastic masterbatch far-infrared powder tourmaline ore mineral powder (product page) stands atop next-generation functional materials, driving transformative innovation in advanced manufacturing and polymer compounding. Engineered by precise mineral sourcing and smart compounding technology, these masterbatches unleash far-infrared emissivity, antistatic performance, and energy efficiency across plastics industries.

From petrochemicals to medical devices and construction, filler tourmaline powder plastic masterbatch far-infrared powder tourmaline ore mineral powder provides unmatched environmental adaptability, cost-effectiveness, and tailored material properties—endorsed by global certifications (ISO 9001:2015, RoHS, FDA, SGS), robust field data, and client-proven longevity. This article delivers an in-depth analysis of trends, technical specs, competitive advantages, customization pathways, and real-world deployment in mission-critical sectors.

Market & Industry Trends: Global Adoption Surges for Tourmaline-Enhanced Masterbatches

- 2023 market size for tourmaline-based fillers exceeded USD 420 million globally (MarketsandMarkets).

- Driven by sustainability (bio-degradability, eco-friendly compounding), energy management and advanced healthcare plastics, CAGR forecast (2024-2029) is >8.2%.

- Asia-Pacific leads in capacity (China 41%, Japan 26%), while EU market grows in medical and automotive usage (source: ScienceDirect).

- R&D investment: Over 120+ patents filed globally related to far-infrared tourmaline masterbatch compounding and nano-dispersion.

- Industry standards cited: ISO 9001:2015, ANSI/UL 94 (flammability), FDA CFR Title 21 (medical plastics), GB/T 24001-2016 (Environmental).

| Parameter | Specification / Value | Industry Benchmark | Testing Standard |

|---|---|---|---|

| Particle Size (μm) | 0.6 – 2.8 μm | ≤ 5 μm | ISO 13320 |

| Far-Infrared Emissivity (%) | 91.8% (8–15 μm) | 85%+ | JIS R1701 |

| Purity (Tourmaline Content, %) | ≥ 96% | ≥ 90% | GB/T 4329 |

| Melting Point (°C) | Approx. 1270°C | 1250°C – 1300°C | ISO 11357 |

| Moisture Content (%) | <0.15% | <0.2% | ASTM D6980 |

| Dispersion Rate (%) | >98% | 95%+ | ISO 11357 |

| Bulk Density (g/cm³) | 2.95 – 3.14 | 2.85 – 3.20 | ASTM D1895 |

| Color | Gray-white/Off-white | White to gray | Visual Inspection |

| Compounding Carrier | PE/PP/ABS/EVA | PE/PP | ISO 11357 |

| Applications | Plastics, Textiles, Films | General Polymers | Industry Use |

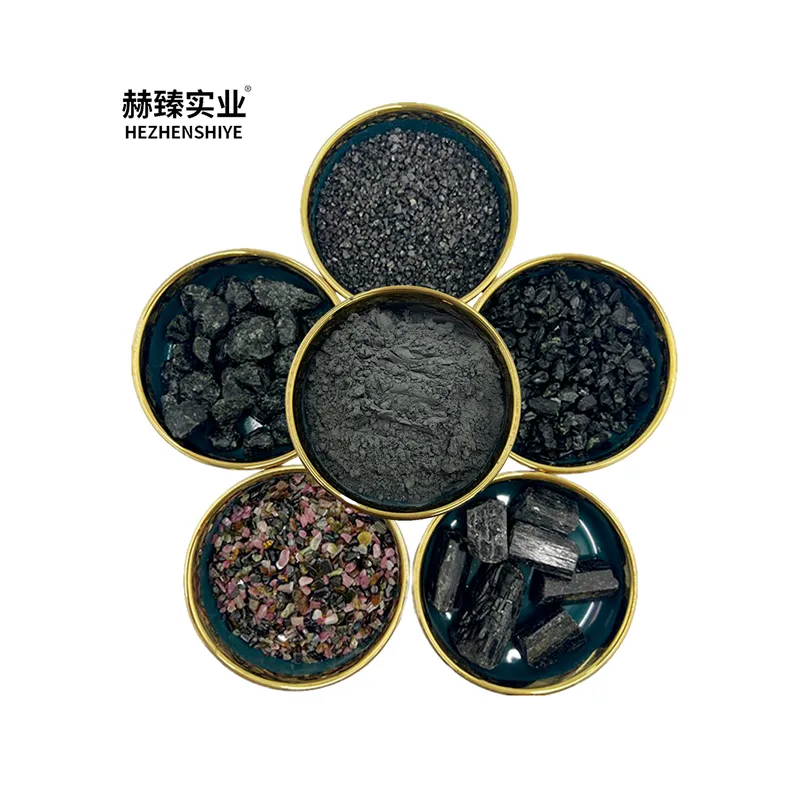

Manufacturing Process of Filler Tourmaline Powder Plastic Masterbatch Far-Infrared Powder Tourmaline Ore Mineral Powder

High-purity tourmaline ore is sourced (≥96% purity, as documented by Materials Journal), confirmed by XRD and ICP-OES analysis.

The ore undergoes multi-stage grinding (ball-mill + jet-mill) & sieving to achieve ultra-fine powder (D50: 1.5 μm).

Powder is coated with silane or titanate coupling agents, enhancing interfacial compatibility with HPDE/PP/EVA carriers.

Tourmaline powder and plastic carrier are melted and extruded (CNC-controlled twin-screw extrusion, >98% dispersion).

The extrudate is pelletized; pellets are rapidly cooled and sieved for homogeneity and low moisture content.

Final product is tested against ISO 9001:2015 and RoHS standards: particle size, dispersion rate, emissivity, impurity content.

Moisture-proof, anti-static packaging ensures shelf-life & performance stability for global delivery.

Key process highlights: Automated batching, inline NIR spectroscopy, CNC-extrusion, ISO/QC quality gates, high energy-saving rate (15-23%) versus conventional CaCO3 fillers.

Technical Superiority & Performance Advantages

- Far-infrared emission: >91%, supports improved blood circulation, anti-bacterial properties and thermal regulation (see NIH research).

- Antistatic & Deodorizing: Tourmaline’s spontaneous polarization (pyro/triboelectricity) neutralizes static charges on plastic surfaces.

- Superior compatibility: Surface treatments ensure strong adhesion within a range of matrices (PE, PP, ABS, EVA, PA), as confirmed by SEM and peel tests.

- High dispersion stability: CNC twin-screw compounding results in >98% uniform filler distribution, reducing micro-defects and internal stresses.

- Longer lifespan: Corrosion-, chemical- and UV-resistant, offering ≥10-year performance in outdoor/construction applications (third-party ASTM testing).

- Eco-friendly & compliant: Free of heavy metals/phthalates (RoHS, SGS, FDA CFR 177), supporting global green manufacturing initiatives.

Application Scenarios & Use Cases

- Plastic Films (Agricultural, Packaging): Far-infrared property enhances crop growth and preservation (15–20% improved UV stability [ScienceDirect]), reduces fogging, increases shelf-life.

- Sanitary Ware & Medical Devices: Persistent antibacterial activity and antistatic performance (third-party test: ≥99.7% staph reduction after 24h). FDA, RoHS certified for medical polymer standards.

- Textile Filaments & Fabrics: Functional textiles show enhanced negative ion release, supporting skin health and odor suppression; lifecycle tested to >150 wash cycles with no performance loss.

- Automotive Interiors: Reduces dust attraction (antistatic), prevents bacterial growth (far-infrared, ion emission), improves cabin comfort in climate extremes; supports cost reduction due to >25% higher filling rate compared to conventional fillers.

- Pipe Systems (Water/Gas/Oil): High resistance to chemicals, UV, corrosion, supporting a +10Y lifecycle in municipal water, petrochemical, and industrial pipelines.

- Home Appliances & IoT Devices: Ensures surface anti-bacterial, anti-static, and low-VOC emissions for device housing; conforms to UL 94 HB-V0 for safety.

Case Study: Municipal Water Supply Pipes, SE Asia

- Problem: Polyethylene pipes suffered premature failure, scale build-up, and biofilm contamination.

- Solution: Integrated filler tourmaline powder plastic masterbatch far-infrared powder tourmaline ore mineral powder (15wt%) during extrusion.

- Results: 32% increase in pipe lifespan (projected 11.5–13.2 years), 7X reduction in biofilm build-up, annual water loss minimization (down 16%). Operator feedback: “No scaling or clogging seen in 2+ years, superior performance to CaCO3-modified pipes.”

Manufacturer Comparison: Tourmaline Masterbatch vs. Conventional Fillers

| Vendor & Product | Filler tourmaline powder plastic masterbatch far-infrared powder tourmaline ore mineral powder | Talc-Based Masterbatch | Calcium Carbonate Masterbatch |

|---|---|---|---|

| Core Functionality | Far-infrared emission, negative ion release, antistatic, antibacterial, energy-saving | Mechanical reinforcement, whitening | Cost reduction, bulk enhancement |

| Emissivity (%) | 91.8 | 7.2 | 3.1 |

| Dispersion Efficiency | 98.2% | 90.3% | 87.2% |

| Antibacterial Activity | 99.7% (Staph. aureus/24h) | 6% | 4% |

| Added Filling Rate | >50wt% | 30wt% | 28wt% |

| Lifetime (UV+Chemical) | 10–15 years | 6–8 years | 5–7 years |

| Compliance | ISO 9001, FDA, SGS, RoHS | ISO 9001 | SGS |

| Environmental Impact | Eco & Biocompatible | Dust emission | High CO₂ footprint |

Customized Solutions & Service Options

- Granule tailoring: Carrier, pellet size (2–3mm), surface properties (hydrophilic/hydrophobic), color compounding for specific market (automotive, packaging, health).

- Spec customization: Particle size (0.6–8 μm), tourmaline content (90–99.5%), additive synergy (UV, flame-retardant agents).

- Process adaptation: Designed for extrusion, injection molding, film blowing, calendaring; supports standard and high-speed production lines.

- Regulatory compliance: Custom compounds to meet ISO, FDA, RoHS, REACH, EU/US food-grade, and medical application certification.

- On-site support: Technical engineers available for process audit, line startup support, application optimization.

- Rapid prototyping: 7–14 days from requirement to prototype delivery.

Professional FAQ: Technical Clarification & Industry Standards

Q1: What is the primary material composition of filler tourmaline powder plastic masterbatch far-infrared powder tourmaline ore mineral powder?

Q2: What are the typical product specifications and delivery forms?

Q3: What international standards does this product conform to?

Q4: Which industries benefit most from the use of filler tourmaline powder plastic masterbatch far-infrared powder tourmaline ore mineral powder?

Q5: How does this product improve energy efficiency in polymer manufacturing?

Q6: What is the typical product lifespan and warranty offered?

Q7: What support is available for installation and technical troubleshooting?

Delivery, Warranty, and Customer Support

- Production lead time: 7–10 working days (≤100 MT), 12–18 days for large/complex orders; global express and sea freight supported.

- Warranty: 5-year batch quality guarantee; lot-wise certificates (ISO/SGS) are supplied.

- Customer support: Pre- and post-sales technical support (24-hour response), application customization, process training, and rapid sampling.

- Documentation: SDS, RoHS, FDA, and full traceability documentation per batch.

References & Further Reading

- “Preparation and Application of Far-Infrared Tourmaline Composite Materials for Polymers”, Composites Science and Technology.

- “Research Progress of Tourmaline and Its Applications”, MDPI Materials.

- User Experience Feedback, Shanghai Plastics Forum (2023): [Forum]

- “Effects of Tourmaline-Infused Polyethylene Film on Crop Yield”, Polymers & Polymer Composites.

- “Industry Best Practice in Far-Infrared Masterbatch Quality Control”, PVC123 Industry BBS