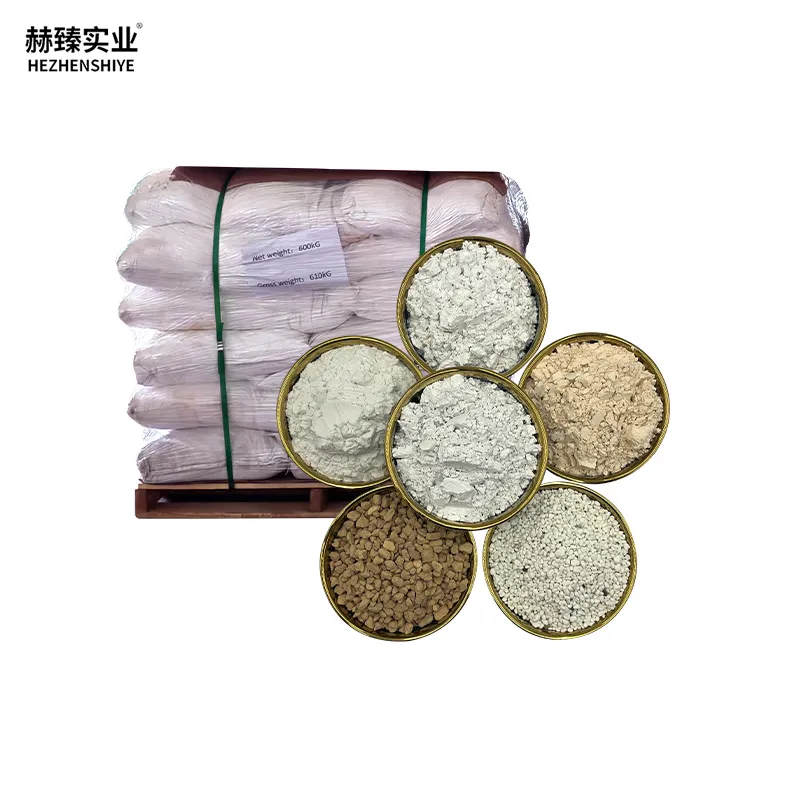

high purity silica

2025.01.14

In the world of cutting-edge industries and advanced material sciences, high purity silica is a cornerstone component, driving innovation and efficiency. Its unmatched qualities and versatility make it a critical resource in diverse applications ranging from electronics to pharmaceuticals. High purity silica, often regarded as an invaluable asset, undergoes rigorous refinement processes to meet the stringent standards demanded by its various applications.

The precision in producing high purity silica cannot be understated. Companies specializing in its manufacture adhere to rigorous protocols to achieve the desired purity levels. This involves advanced purification techniques such as chemical vapor deposition and hydrolysis processes. Manufacturers must operate in highly controlled environments to eliminate contamination and ensure the reliability of the final product. This meticulous approach underscores the expertise and commitment required to provide high purity silica that trusts industry professionals and meets regulators' exacting standards. Security and authenticity are also critical when sourcing high purity silica. Trustworthy suppliers must provide transparency in their production processes and verification of their quality standards. Certificates of analysis (CoA) and material safety data sheets (MSDS) should accompany purchases, offering reassurance of the product’s consistency and purity. Engaging with ISO-certified manufacturers further enhances the confidence in the quality of the silica provided, ensuring it meets international shipment and application demands flawlessly. In conclusion, high purity silica is not merely a component; it is an enabler of innovation and sustainability across multiple high-stakes industries. Its refined qualities, backed by expert production and quality assurance, reflect its essential role in technological advancement and environmental responsibility. As industries continue to evolve, the reliance on and demand for high purity silica will undoubtedly grow, reinforcing its status as a cornerstone material in the modern world.

The precision in producing high purity silica cannot be understated. Companies specializing in its manufacture adhere to rigorous protocols to achieve the desired purity levels. This involves advanced purification techniques such as chemical vapor deposition and hydrolysis processes. Manufacturers must operate in highly controlled environments to eliminate contamination and ensure the reliability of the final product. This meticulous approach underscores the expertise and commitment required to provide high purity silica that trusts industry professionals and meets regulators' exacting standards. Security and authenticity are also critical when sourcing high purity silica. Trustworthy suppliers must provide transparency in their production processes and verification of their quality standards. Certificates of analysis (CoA) and material safety data sheets (MSDS) should accompany purchases, offering reassurance of the product’s consistency and purity. Engaging with ISO-certified manufacturers further enhances the confidence in the quality of the silica provided, ensuring it meets international shipment and application demands flawlessly. In conclusion, high purity silica is not merely a component; it is an enabler of innovation and sustainability across multiple high-stakes industries. Its refined qualities, backed by expert production and quality assurance, reflect its essential role in technological advancement and environmental responsibility. As industries continue to evolve, the reliance on and demand for high purity silica will undoubtedly grow, reinforcing its status as a cornerstone material in the modern world.

Pervious

Next