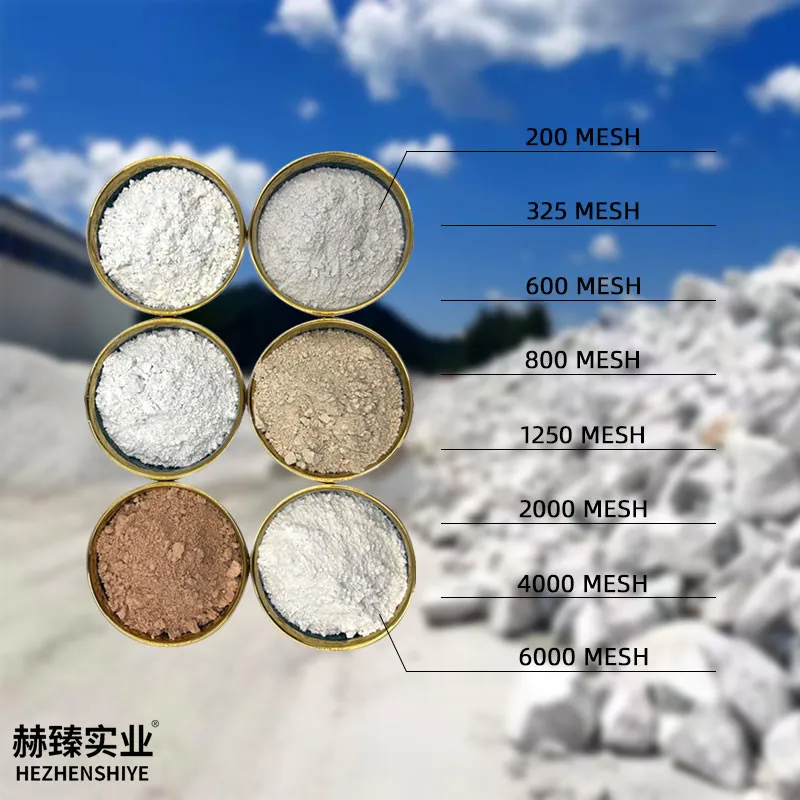

industrial talc powder

2025.03.03

Industrial talc powder, a finely ground natural mineral, has significantly diversified its application across various industries, providing solutions that emphasize efficiency, quality, and sustainability. As industries expand, the demand for materials offering multifunctionality and stability increases, placing industrial talc powder at the forefront of innovation.

Moreover, the ceramics industry has long relied on talc to improve the physical properties of firing processes. By promoting even heat distribution and preventing shrinkage and cracking, talc ensures the durability and quality of ceramic products. Ceramists and material scientists frequently cite talc's stabilizing effects as crucial to advancing the development of high-performance ceramics, meeting the rigorous demands of both traditional and modern applications. In pharmaceuticals, talc holds its ground as a trusted excipient, facilitating the manufacture of tablets and powders. Its lubricative characteristic aids in the smooth tableting process while ensuring the stability and efficacy of the final product. Pharmaceutical authorities vouch for the purity and safety of pharmaceutical-grade talc, bolstering its reputation as a reliable industry staple. Experts continually research and explore new applications and developments in talc technology. The advancements in nanotechnology and material science expand the horizon of talc's use, driving interest from sectors eager to optimize product performance and environmental impact. Trustworthiness in talc products is maintained through rigorous testing and quality assurance measures, upholding the integrity and reliability that industries demand. The consistent performance of industrial talc powder across varied applications establishes it as a material of authoritative significance, relied upon by industry experts, engineers, and scientists alike. As industries search for materials that blend functionality with sustainability, industrial talc powder emerges as a dynamic solution. Its versatility and enduring relevance underscore its standing in the manufacturing hierarchy. The confidence of industry leaders and scientific communities in industrial talc's capabilities reaffirms its essential role in shaping future innovations.

Moreover, the ceramics industry has long relied on talc to improve the physical properties of firing processes. By promoting even heat distribution and preventing shrinkage and cracking, talc ensures the durability and quality of ceramic products. Ceramists and material scientists frequently cite talc's stabilizing effects as crucial to advancing the development of high-performance ceramics, meeting the rigorous demands of both traditional and modern applications. In pharmaceuticals, talc holds its ground as a trusted excipient, facilitating the manufacture of tablets and powders. Its lubricative characteristic aids in the smooth tableting process while ensuring the stability and efficacy of the final product. Pharmaceutical authorities vouch for the purity and safety of pharmaceutical-grade talc, bolstering its reputation as a reliable industry staple. Experts continually research and explore new applications and developments in talc technology. The advancements in nanotechnology and material science expand the horizon of talc's use, driving interest from sectors eager to optimize product performance and environmental impact. Trustworthiness in talc products is maintained through rigorous testing and quality assurance measures, upholding the integrity and reliability that industries demand. The consistent performance of industrial talc powder across varied applications establishes it as a material of authoritative significance, relied upon by industry experts, engineers, and scientists alike. As industries search for materials that blend functionality with sustainability, industrial talc powder emerges as a dynamic solution. Its versatility and enduring relevance underscore its standing in the manufacturing hierarchy. The confidence of industry leaders and scientific communities in industrial talc's capabilities reaffirms its essential role in shaping future innovations.

Pervious

Next