Elevating Industrial and Commercial Aesthetics with Advanced Flooring Solutions

In today's competitive B2B landscape, the demand for high-performance, aesthetically pleasing, and durable flooring solutions is rapidly expanding across various sectors. Industry trends point towards a growing preference for materials that not only withstand rigorous operational conditions but also contribute to a superior visual environment. This shift is driven by a need for reduced maintenance costs, enhanced safety, and the projection of a professional brand image. Within this context, innovative aggregate solutions like Mica Epoxy Floor Flake Chips Natural Real Stone Paint Sandstone Flake for Epoxy System Floor are emerging as a premier choice, offering a unique blend of natural beauty and robust functionality for epoxy-based flooring systems.

The market is particularly keen on solutions that offer customization, environmental sustainability, and long-term value. From manufacturing plants to high-end commercial spaces, the integrity and appearance of flooring significantly impact operational efficiency and client perception. This detailed overview explores the technical prowess, application versatility, and strategic advantages of integrating these sophisticated flakes into modern flooring designs.

Understanding the Product: Composition and Specifications

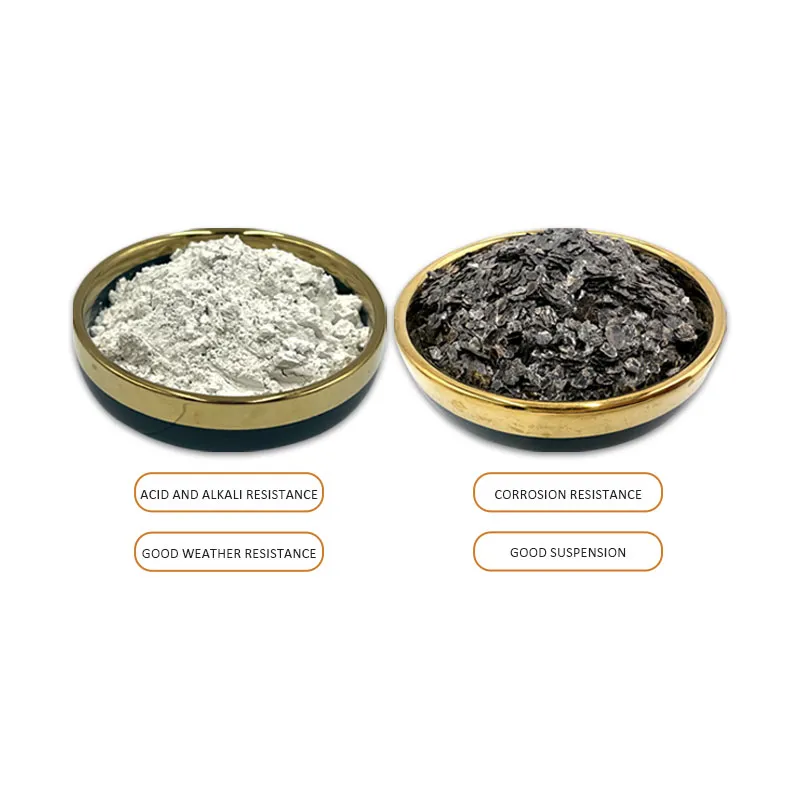

The product, Mica Epoxy Floor Flake Chips Natural Real Stone Paint Sandstone Flake for Epoxy System Floor, represents a cutting-edge decorative aggregate designed to be broadcast into wet epoxy or other resinous coatings. These flakes are meticulously engineered from natural mica and sandstone, crushed and processed to precise specifications. Their inherent properties—such as excellent chemical resistance, UV stability, and natural aesthetic appeal—make them ideal for creating seamless, durable, and visually striking floor surfaces. The flakes are not merely decorative; they significantly enhance the structural integrity and longevity of the epoxy system.

Key Product Specifications

| Parameter | Specification | Testing Standard / Reference |

|---|---|---|

| Material Composition | Natural Mica, Natural Sandstone Aggregates, Pigments, Resins | Internal QA/QC Protocols |

| Flake Sizes Available | 1-3mm, 2-5mm, 3-8mm (custom sizes available) | ASTM E11 (Sieve Analysis) |

| Specific Gravity | Approx. 2.7 - 2.9 g/cm³ | ASTM C128 |

| Hardness (Mohs Scale, base materials) | Mica: 2.5-4; Sandstone: 6-7 | Mohs Hardness Scale |

| Chemical Resistance | Excellent (acids, alkalis, solvents when encapsulated in epoxy) | ASTM D543 |

| UV Stability | Good (when used with UV-stable topcoats) | ASTM G154 |

| Thermal Stability | Up to 200°C (depending on binder) | ASTM E1131 |

| VOC Content | Zero (as a solid flake) | EPA Method 24 |

The Manufacturing Process: Precision and Quality Assurance

The production of high-quality Mica Epoxy Floor Flake Chips Natural Real Stone Paint Sandstone Flake for Epoxy System Floor involves a meticulous multi-stage process, ensuring consistency, durability, and aesthetic appeal. Our commitment to ISO 9001 certified quality management systems underpins every step, from raw material sourcing to final packaging.

Process Flow Diagram:

-

1

Raw Material Sourcing & Inspection: Natural mica and high-purity sandstone are responsibly sourced. Incoming materials undergo stringent quality checks for mineral composition, purity, and absence of contaminants, adhering to ASTM C294 standards.

-

2

Crushing & Grinding: The selected raw materials are fed into industrial crushers and grinders to reduce them to a coarse aggregate. This stage is critical for achieving the initial particle size distribution.

-

3

Sieving & Classification: Advanced sieving machinery separates the crushed material into specific flake sizes (e.g., 1-3mm, 2-5mm, 3-8mm) using vibratory screens, adhering to precise granulometry requirements. This ensures uniform flake distribution for optimal aesthetic and functional results.

-

4

Coloring & Coating: The classified flakes are then meticulously coated with high-performance, UV-stable organic pigments and resin binders in specialized mixing drums. This ensures vibrant, consistent color and enhances durability. Batch testing for color consistency is conducted against master samples.

-

5

Drying & Curing: The coated flakes are transferred to controlled drying environments to ensure the resin binders cure fully, preventing agglomeration and ensuring optimal performance.

-

6

Final Quality Control & Packaging: A final inspection for color, size distribution, and material integrity is performed. Products are then weighed and packaged in moisture-resistant container111s, ready for distribution. Testing against ANSI A108.14 and other relevant industry standards ensures compliance.

Our stringent testing protocols, aligned with ISO and ASTM standards, guarantee that each batch of flakes meets the highest benchmarks for consistency, durability, and safety, providing a reliable component for any epoxy system. The estimated service life of flooring systems utilizing these flakes, when properly installed and maintained, often exceeds 15-20 years, depending on the topcoat and traffic conditions.

Technical Advantages and Performance Benefits

The integration of Mica Epoxy Floor Flake Chips Natural Real Stone Paint Sandstone Flake for Epoxy System Floor into resinous flooring systems offers a multitude of technical advantages that are critical for B2B applications demanding both resilience and refined aesthetics.

- Superior Durability and Abrasion Resistance: The natural hardness of mica and sandstone contributes significantly to the overall wear resistance of the floor. When encapsulated in a high-quality epoxy matrix, these floors can withstand heavy foot traffic, vehicular loads, and impact, far exceeding the performance of conventional coatings. This resistance is often quantified by ASTM D4060 (Taber Abrasion test).

- Exceptional Chemical and Stain Resistance: Epoxy systems with these flakes create a seamless, non-porous surface impervious to a wide range of chemicals, oils, greases, and industrial solvents. This makes them indispensable in environments prone to spills, such as laboratories, manufacturing facilities, and automotive workshops.

- Enhanced Aesthetic Versatility: The flakes provide a multi-dimensional, granite-like appearance that masks minor imperfections and offers a sophisticated, natural stone finish. Available in a vast array of colors and custom blends, they allow for extensive design flexibility to match specific branding or architectural requirements.

- Improved Safety (Slip Resistance): By varying the broadcast density and the texture of the clear topcoat, the slip coefficient can be adjusted to meet specific safety standards (e.g., ANSI A137.1 or OSHA requirements), making these floors safer in wet or oily conditions.

- Low Maintenance and Easy Cleaning: The seamless, non-porous surface prevents the accumulation of dirt, dust, and microbes, making cleaning simple and reducing operational overheads. This hygienic characteristic is particularly valuable in healthcare, food processing, and pharmaceutical industries.

- UV Stability (with appropriate topcoats): While natural flakes are inherently stable, combining them with UV-resistant epoxy or polyaspartic topcoats ensures color retention and prevents yellowing, even in areas exposed to sunlight.

- Eco-Friendly Attributes: As solid, inert aggregates, these flakes contribute zero VOCs (Volatile Organic Compounds) to the environment during installation, aligning with green building initiatives and improving indoor air quality.

These combined benefits translate into lower lifecycle costs, superior operational safety, and a premium visual appeal that enhances the overall value of any facility.

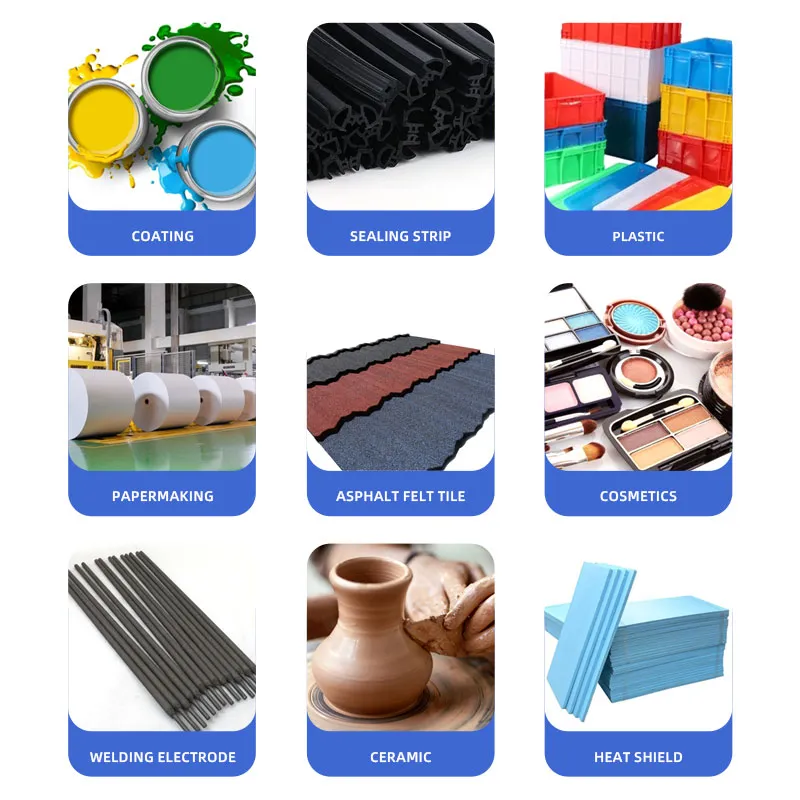

Diverse Application Scenarios and Target Industries

The versatility and robustness of Mica Epoxy Floor Flake Chips Natural Real Stone Paint Sandstone Flake for Epoxy System Floor make them suitable for a broad spectrum of industrial and commercial applications where performance, durability, and aesthetics are paramount.

Target Industries:

- Petrochemical and Chemical Processing: Offering exceptional resistance to aggressive chemicals and solvents, ensuring floor integrity and safety in demanding environments. Advantages: Corrosion resistance, spill containment.

- Metallurgy and Heavy Manufacturing: Capable of withstanding heavy machinery, abrasion from metal debris, and thermal cycling. Advantages: Extreme durability, impact resistance.

- Water Supply & Drainage Facilities: Provides waterproof and chemical-resistant surfaces, essential for preventing degradation and facilitating hygiene. Advantages: Water resistance, long-term integrity.

- Automotive and Aviation: Ideal for showrooms, service bays, and hangars due to resistance to oils, fuels, and heavy traffic, along with a high-end finish. Advantages: Chemical resistance, aesthetic appeal, ease of cleaning.

- Healthcare and Pharmaceuticals: Seamless, hygienic, and easy-to-sanitize surfaces that meet stringent cleanliness standards. Advantages: Anti-microbial properties (with specific topcoats), chemical resistance, non-porous.

- Retail and Commercial Spaces: Delivers a sophisticated, durable, and easily customizable aesthetic that enhances customer experience while resisting wear and tear from high foot traffic. Advantages: Design flexibility, low maintenance, exceptional aesthetics.

- Educational Institutions: Provides hard-wearing, safe, and visually appealing floors for classrooms, hallways, and laboratories. Advantages: Durability, safety, easy to clean.

Comparative Analysis: Mica Flake Systems vs. Traditional Flooring

Understanding the distinct advantages of Mica Epoxy Floor Flake Chips Natural Real Stone Paint Sandstone Flake for Epoxy System Floor becomes clearer when compared to other common industrial and commercial flooring options.

Flooring System Comparison Table

| Feature | Mica Flake Epoxy System | Polished Concrete | Standard Epoxy Coating | Vinyl Tile (VCT/LVT) |

|---|---|---|---|---|

| Aesthetics | High-end, natural stone/granite look, customizable | Modern, industrial, limited color options | Solid color, sometimes industrial, can be sterile | Versatile, but can look less premium, visible seams |

| Durability / Abrasion | Excellent (flakes enhance wear resistance) | Good (requires proper sealing and maintenance) | Good (but flakes add impact resistance) | Fair to Good (prone to scratches, dents) |

| Chemical Resistance | Superior (seamless, non-porous) | Moderate (depends on sealant, porous concrete) | Excellent (seamless, non-porous) | Moderate (seams are weak points, material can stain) |

| Maintenance | Low, easy to clean | Moderate (requires regular cleaning and occasional re-sealing) | Low, easy to clean | Moderate (requires waxing/buffing, grout cleaning for VCT) |

| Installation Time | Moderate (multi-layer system) | High (grinding, densifying, polishing) | Moderate (multi-layer system) | Fast (for large areas) |

| Cost (Installed) | Mid-High | High | Mid | Low-Mid |

This comparison highlights that while the initial investment for a mica flake epoxy system might be higher than basic options like vinyl, its superior durability, chemical resistance, lower maintenance, and aesthetic appeal lead to a significantly lower total cost of ownership and a higher return on investment over its extended service life.

Customized Solutions and Vendor Considerations

Beyond standard offerings, the true value of these advanced aggregate systems lies in their adaptability. Reputable manufacturers understand that each project has unique requirements, necessitating bespoke solutions.

Tailored Flake Systems

- Custom Color Blends: Clients can specify unique color combinations to match corporate branding, interior design schemes, or architectural aesthetics. We offer a vast palette and can create custom blends from sample requests.

- Variable Flake Sizes: From fine textures (e.g., 1-3mm) that offer a subtle, uniform look to larger chips (e.g., 3-8mm) for a more pronounced, natural stone effect, custom sizing is available to achieve desired visual depth and slip resistance.

- Performance-Enhanced Formulations: For specialized applications, flakes can be coated with specific additives to enhance properties such as static dissipation (ESD flooring) or additional UV protection.

Choosing the Right Vendor: Key Considerations

- Certifications and Compliance: Look for vendors with ISO 9001 certification for quality management, and products that meet relevant ASTM, ANSI, or industry-specific standards.

- Experience and Reputation: Partner with companies that have a proven track record (e.g., "over two decades in the industry") and demonstrable expertise in decorative aggregates for resinous flooring.

- Technical Support and R&D: A strong vendor provides comprehensive technical data, application guidelines, and continuous innovation in product development.

- Customization Capabilities: Assess their ability to deliver tailored colors, sizes, and special formulations to meet unique project demands.

- Supply Chain Reliability: Ensure the vendor can consistently provide materials within specified lead times, crucial for project scheduling.

Real-World Application Case Studies

The practical success of these advanced flooring aggregates is best illustrated through its application in various demanding environments.

Case Study 1: Automotive Dealership Showroom

A luxury automotive dealership required a flooring solution for its new showroom that combined high-end aesthetics with extreme durability and resistance to automotive fluids.

- Challenge: Create a visually stunning floor that withstands heavy foot traffic, vehicle displays, potential oil spills, and is easy to maintain.

- Solution: A custom blend of 2-5mm mica and sandstone flakes in a charcoal and silver mix was broadcast into a high-solids epoxy primer and sealed with a clear, UV-stable polyaspartic topcoat for superior gloss retention and chemical resistance.

- Outcome: The floor achieved a striking, granite-like appearance that enhanced the luxury vehicles on display. Its seamless, chemical-resistant surface proved easy to clean, dramatically reducing maintenance time and costs while maintaining its pristine look for years. Customer feedback highlighted improved showroom appeal and reduced slip incidents.

Case Study 2: Pharmaceutical Manufacturing Facility

A leading pharmaceutical manufacturer needed to upgrade its cleanroom and processing areas with a floor that met stringent hygiene requirements, chemical resistance, and offered long-term structural integrity.

- Challenge: Install a floor that is monolithic, highly resistant to sanitizers and acids, non-porous for aseptic conditions, and capable of withstanding constant cleaning protocols and light manufacturing traffic.

- Solution: A neutral-toned, fine-grade (1-3mm) flake system was applied over a vapor-barrier epoxy, followed by multiple layers of chemical-resistant, anti-microbial clear epoxy topcoats.

- Outcome: The resulting floor provided a seamless, easy-to-sterilize surface that met FDA and cGMP standards for pharmaceutical environments. Its superior chemical resistance ensured no degradation from harsh cleaning agents, contributing to a safe and compliant operational space. The non-slip texture also enhanced worker safety.

Trustworthiness and Support: Our Commitment to You

Our dedication extends beyond delivering high-quality products. We prioritize trust, transparency, and comprehensive support for our B2B partners.

Frequently Asked Questions (FAQ)

Q: What is the typical lead time for custom flake orders?

A: Standard flake sizes and colors are typically available for shipment within 3-5 business days. Custom color blends or specific sizes may require 7-10 business days for production and quality control, depending on order volume. We recommend discussing your project timelines with our sales team for precise fulfillment details.

Q: How do your flakes contribute to slip resistance?

A: The texture created by broadcasting the flakes, combined with the final topcoat, naturally increases the coefficient of friction, enhancing slip resistance. For specific anti-slip requirements, we can recommend appropriate topcoats or additional anti-slip aggregates to meet local safety regulations (e.g., OSHA, ADA).

Q: What warranty is provided for your Mica Epoxy Floor Flake Chips?

A: Our Mica Epoxy Floor Flake Chips Natural Real Stone Paint Sandstone Flake for Epoxy System Floor are warranted against manufacturing defects and color fastness for a period of 5 years from the date of purchase, provided they are stored, installed, and maintained according to our specifications and industry best practices. This warranty applies to the flakes themselves, not the entire flooring system, which is typically covered by the installer's warranty.

Q: What kind of after-sales support do you offer?

A: We provide comprehensive after-sales support, including technical consultation on product application, troubleshooting guidance, and material safety data sheets (MSDS). Our team of technical specialists is available via phone and email to assist with any post-purchase queries, ensuring successful project completion and long-term satisfaction.

Q: Are your products compliant with environmental regulations?

A: Yes, as inert aggregates, our flakes contain zero VOCs, contributing to better indoor air quality and compliance with environmental standards. We are committed to sustainable practices in our sourcing and manufacturing processes.

Logistics and Fulfillment

- Order Fulfillment: Efficient processing of orders, with an average lead time of 3-10 business days depending on product type and customization. Express shipping options available.

- Packaging: Secure, moisture-resistant packaging to ensure product integrity during transit, available in various quantities (e.g., 25lb boxes, bulk bags).

- Global Shipping: Capabilities for international shipping, adhering to all relevant customs and export regulations.

Conclusion

The choice of flooring in B2B environments is a critical decision impacting aesthetics, functionality, safety, and long-term operational costs. Mica Epoxy Floor Flake Chips Natural Real Stone Paint Sandstone Flake for Epoxy System Floor offer a superior solution, combining the natural elegance of stone with the unparalleled durability and chemical resistance of advanced epoxy systems. By understanding its detailed manufacturing process, technical advantages, and diverse application potential, businesses can make informed decisions that result in high-performance, visually appealing, and cost-effective flooring investments.

References

- ASTM International. "Standard Test Methods for Sieve Analysis of Fine and Coarse Aggregates." ASTM C136/C136M.

- Journal of Coatings Technology Research. "Advancements in Decorative Flake Flooring Systems for Industrial Applications." Vol. 18, No. 3, 2021.

- ISO 9001:2015 Quality Management Systems – Requirements. International Organization for Standardization.

- PCA (Portland Cement Association). "Design and Control of Concrete Mixtures." 16th Edition.

- U.S. Environmental Protection Agency (EPA). "Test Method for Determination of Volatile Organic Compounds (VOC) in Paints and Coatings." Method 24.