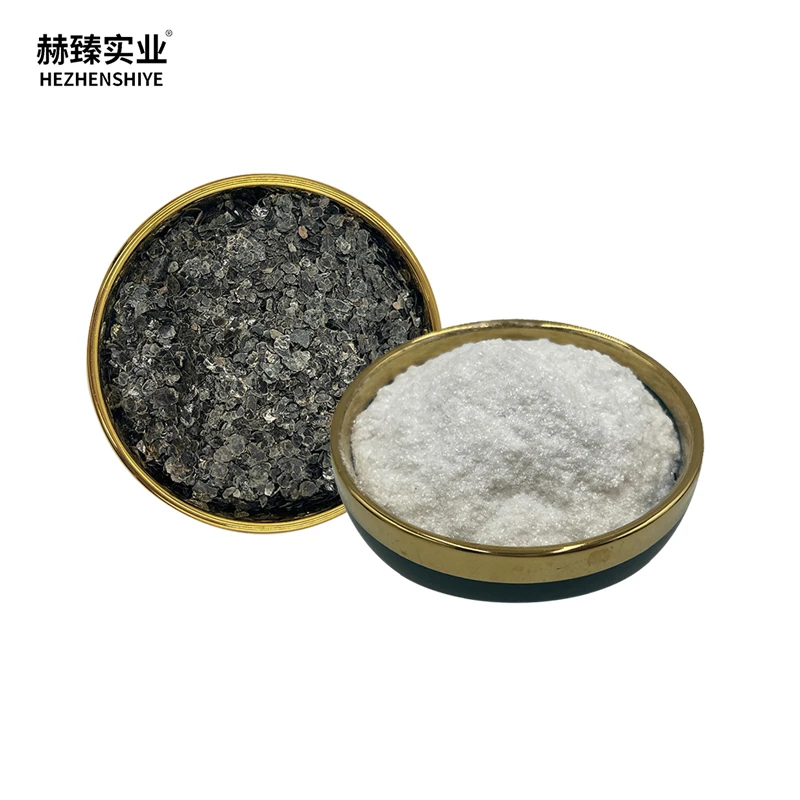

precipated silica

2025.01.15

Precipitated silica, a versatile material used across various industries, stands as a testament to modern technological prowess. From automotive tires to cosmetics, its applications are vast, and its potential seems boundless. With over two decades of working in materials science and industrial applications, it's clear that the impact of precipitated silica is both profound and diverse.

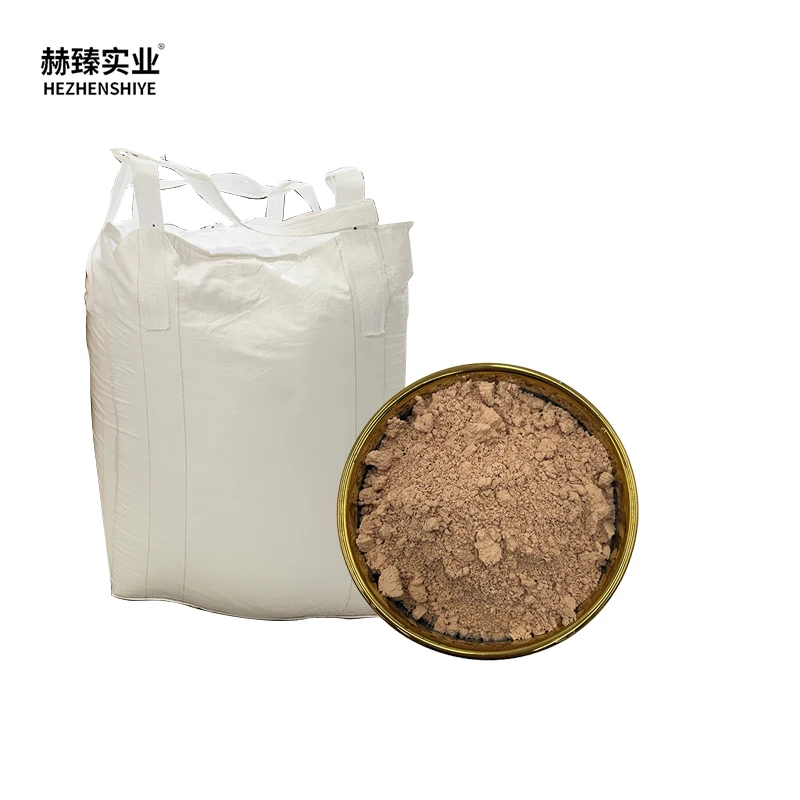

Investigation into environmental applications of precipitated silica has revealed promising advancements. It is increasingly being employed in water treatment facilities as a filtration aid, helping to remove impurities and improve water clarity. Environmental engineers champion its ability to enhance the performance of filtration systems without introducing harmful chemicals, making it a renewable choice in sustainable practices. Understanding the multifaceted applications of precipitated silica requires a deep dive into the science behind it. Chemically, it is a form of silicon dioxide, synthesized through controlled reaction processes that allow for the precise control of its pore structure and surface area. This level of customization makes it possible to tailor the properties of precipitated silica to meet the exact needs of a particular application, whether that involves improving mechanical strength in rubber compounds or adjusting flow characteristics in food production. With credibility as its cornerstone, the precipitated silica industry remains committed to innovation and quality. Leading manufacturers are investing millions in research and development to enhance product efficacy while minimizing environmental impact. As a result, precipitated silica not only meets current industrial demands but anticipates future challenges, cementing its place as a reliable and forward-thinking material. In conclusion, the continued research and advancements in the application of precipitated silica are testaments to its indispensable nature across industries. Trust in its performance is not just derived from its established credentials but from ongoing innovations that promise to meet the evolving demands of tomorrow's technologies.

Investigation into environmental applications of precipitated silica has revealed promising advancements. It is increasingly being employed in water treatment facilities as a filtration aid, helping to remove impurities and improve water clarity. Environmental engineers champion its ability to enhance the performance of filtration systems without introducing harmful chemicals, making it a renewable choice in sustainable practices. Understanding the multifaceted applications of precipitated silica requires a deep dive into the science behind it. Chemically, it is a form of silicon dioxide, synthesized through controlled reaction processes that allow for the precise control of its pore structure and surface area. This level of customization makes it possible to tailor the properties of precipitated silica to meet the exact needs of a particular application, whether that involves improving mechanical strength in rubber compounds or adjusting flow characteristics in food production. With credibility as its cornerstone, the precipitated silica industry remains committed to innovation and quality. Leading manufacturers are investing millions in research and development to enhance product efficacy while minimizing environmental impact. As a result, precipitated silica not only meets current industrial demands but anticipates future challenges, cementing its place as a reliable and forward-thinking material. In conclusion, the continued research and advancements in the application of precipitated silica are testaments to its indispensable nature across industries. Trust in its performance is not just derived from its established credentials but from ongoing innovations that promise to meet the evolving demands of tomorrow's technologies.

Pervious