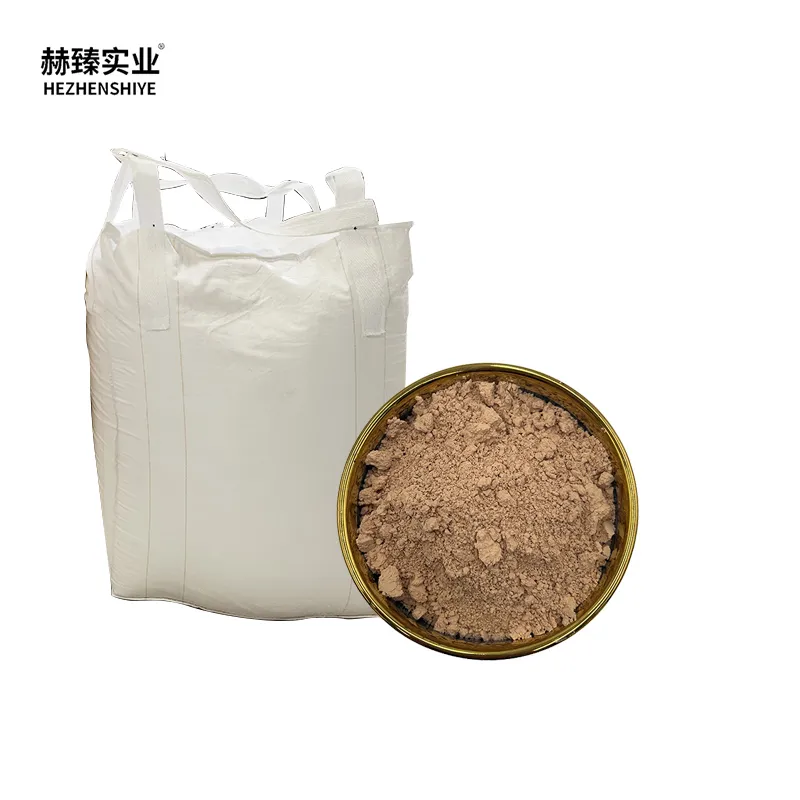

silica fume price

2025.01.11

Silica fume, an invaluable byproduct of silicon and ferrosilicon alloy production, has increasingly become a focal point for industries seeking to enhance concrete performance. Its rising demand has inevitably led to fluctuating prices, guided by various market factors. Understanding these dynamics is crucial for industry stakeholders looking to manage costs effectively.

Technological advancements in production methods can influence silica fume pricing, albeit indirectly. Efficient production processes can reduce costs and waste, which might allow producers to offer competitive prices or boost profit margins. Companies investing in such innovations tend to adapt better to price volatility, providing value to their clients through stable pricing. For buyers and industry professionals, strategic procurement is essential to mitigate price risks. Engaging with multiple suppliers and locking in prices through long-term contracts during periods of stability can be effective strategies. Additionally, keeping abreast of market trends and technological developments can aid in anticipating price shifts and adjusting procurement strategies accordingly. Moreover, leveraging local or regional suppliers can provide additional cost benefits, reducing transportation expenses and improving supply chain efficiency. Building strong relationships with suppliers can also create opportunities for negotiation, favorable terms, and prioritized service in times of high demand. In conclusion, while silica fume prices are influenced by an array of factors including market demand, transportation logistics, regulatory environments, and product quality, buyers can navigate this complex landscape through informed strategies and partnerships. Keeping a watchful eye on industry trends and investing in relationships with versatile suppliers are essential to optimizing procurement and maintaining budgetary control amidst fluctuating market conditions. Understanding these aspects with an authoritative approach ensures trust and reliability in managing silica fume-related projects, achieving both economical and high-performance outcomes.

Technological advancements in production methods can influence silica fume pricing, albeit indirectly. Efficient production processes can reduce costs and waste, which might allow producers to offer competitive prices or boost profit margins. Companies investing in such innovations tend to adapt better to price volatility, providing value to their clients through stable pricing. For buyers and industry professionals, strategic procurement is essential to mitigate price risks. Engaging with multiple suppliers and locking in prices through long-term contracts during periods of stability can be effective strategies. Additionally, keeping abreast of market trends and technological developments can aid in anticipating price shifts and adjusting procurement strategies accordingly. Moreover, leveraging local or regional suppliers can provide additional cost benefits, reducing transportation expenses and improving supply chain efficiency. Building strong relationships with suppliers can also create opportunities for negotiation, favorable terms, and prioritized service in times of high demand. In conclusion, while silica fume prices are influenced by an array of factors including market demand, transportation logistics, regulatory environments, and product quality, buyers can navigate this complex landscape through informed strategies and partnerships. Keeping a watchful eye on industry trends and investing in relationships with versatile suppliers are essential to optimizing procurement and maintaining budgetary control amidst fluctuating market conditions. Understanding these aspects with an authoritative approach ensures trust and reliability in managing silica fume-related projects, achieving both economical and high-performance outcomes.

Pervious

Next