silica manufacturers

2025.01.10

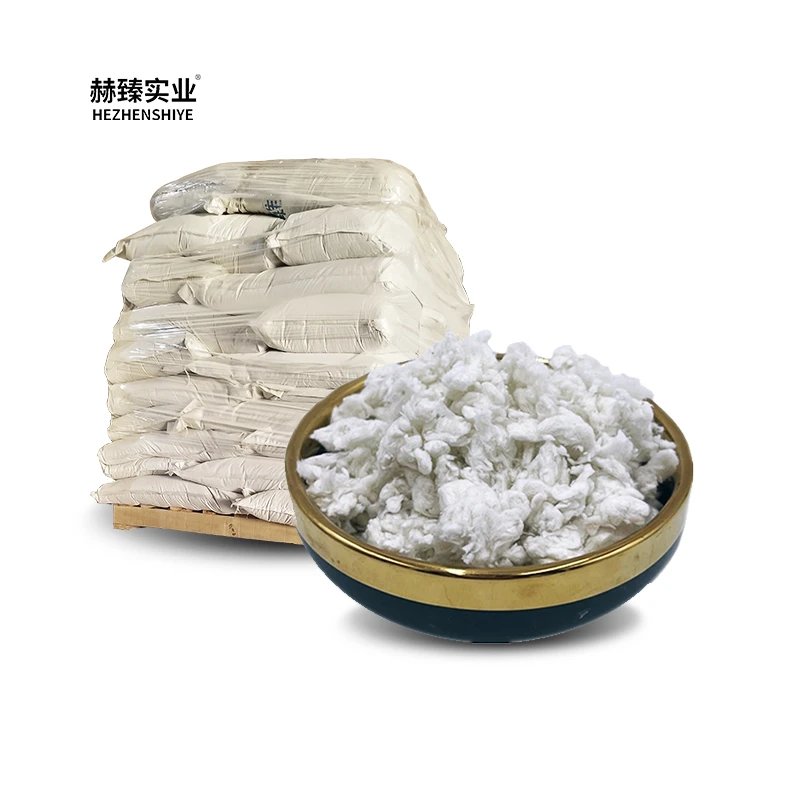

Silica, a multifaceted mineral, has become an indispensable asset in the modern industrial landscape. As a key component in various applications, it serves a critical role across multiple sectors, including construction, electronics, and filtration. The global demand for silica is steadily increasing, making its manufacturers pivotal to advancing technological development and industrial sustainability.

Furthermore, transparency in manufacturing practices bolsters consumer trust, as companies provide detailed traceability of their silica products. This transparency is crucial in sectors like pharmaceuticals and food manufacturing, where stringent regulations dictate the use of high-grade, contaminant-free silica. As silica's applications broaden, from traditional sectors to cutting-edge technology, manufacturers are exploring novel opportunities in emerging markets. Recent innovations include its use as a reinforcement agent in 3D printing materials and developing silica-based aerogels for insulation, showcasing the mineral's versatility and future potential. Ultimately, communicating this experience and expertise establishes a strong connection with potential clients seeking reliable silica solutions. Manufacturers are encouraged to engage in proactive knowledge sharing through case studies, expert interviews, and detailed product documentation, emphasizing their mastery of silica applications and commitment to excellence. Such initiatives are not only beneficial for customer relations but also enhance their online visibility and search engine ranking, effectively integrating SEO strategies into their market approach. In this evolving market, manufacturers who creatively harness their expertise, authoritativeness, and trustworthiness in producing and innovating silica can elevate their presence significantly, meeting the demands of a future-oriented economy. Such a strategic approach positions them as industry leaders, driving forward the sustainability and technological advancement agendas.

Furthermore, transparency in manufacturing practices bolsters consumer trust, as companies provide detailed traceability of their silica products. This transparency is crucial in sectors like pharmaceuticals and food manufacturing, where stringent regulations dictate the use of high-grade, contaminant-free silica. As silica's applications broaden, from traditional sectors to cutting-edge technology, manufacturers are exploring novel opportunities in emerging markets. Recent innovations include its use as a reinforcement agent in 3D printing materials and developing silica-based aerogels for insulation, showcasing the mineral's versatility and future potential. Ultimately, communicating this experience and expertise establishes a strong connection with potential clients seeking reliable silica solutions. Manufacturers are encouraged to engage in proactive knowledge sharing through case studies, expert interviews, and detailed product documentation, emphasizing their mastery of silica applications and commitment to excellence. Such initiatives are not only beneficial for customer relations but also enhance their online visibility and search engine ranking, effectively integrating SEO strategies into their market approach. In this evolving market, manufacturers who creatively harness their expertise, authoritativeness, and trustworthiness in producing and innovating silica can elevate their presence significantly, meeting the demands of a future-oriented economy. Such a strategic approach positions them as industry leaders, driving forward the sustainability and technological advancement agendas.

Pervious

Next