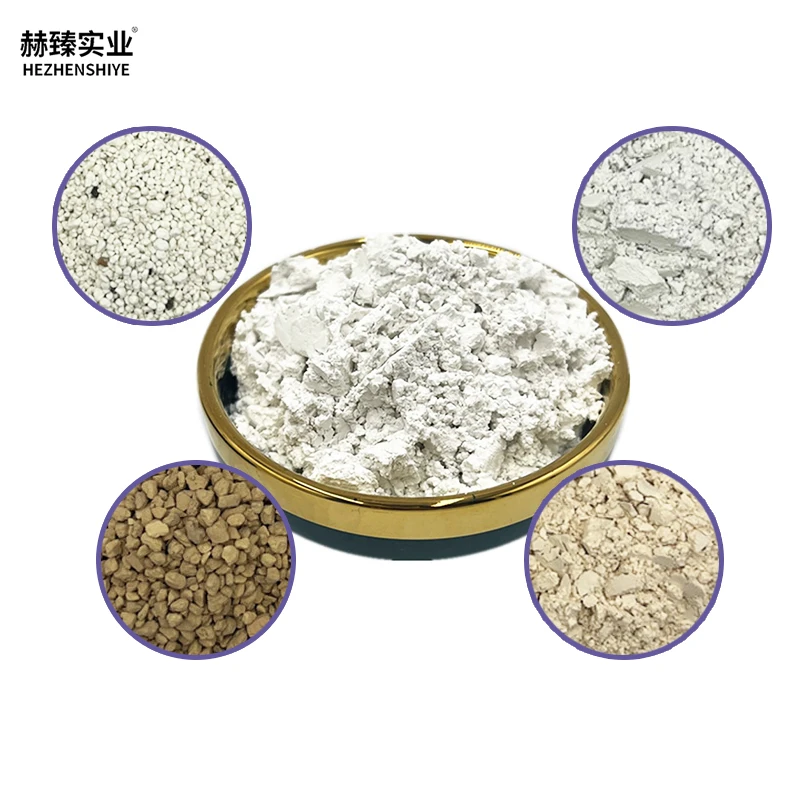

silicon dioxide additive

2025.01.14

The use of silicon dioxide as an additive is revolutionizing various industries due to its versatility and unique properties. Widely recognized for its role in food and pharmaceuticals, silicon dioxide acts as an anti-caking agent, promoting better product flow and preventing clumping. Beyond these industries, its applications extend into cosmetic, paint, and rubber manufacturing, underscoring the breadth of its utility. Let's explore how businesses are leveraging this compound to enhance their products, boost efficiency, and maintain high standards of quality and safety.

In industrial applications, such as paints and coatings, silicon dioxide contributes significantly to the product's resilience. By improving the abrasion resistance and durability of coatings, it helps in extending the lifespan and maintaining the aesthetic properties of the surfaces applied. Automotive and construction industries rely on these attributes to provide long-lasting, visually appealing finishes, showcasing silicon dioxide's vital role in product enhancement. Furthermore, in the rubber industry, silicon dioxide is used as a reinforcing filler, enhancing the mechanical properties of rubber. Producers of automotive tires and industrial rubber products incorporate silicon dioxide to achieve superior performance, whether it be in terms of grip, longevity, or resistance to environmental factors. The adoption of silicon dioxide as an additive across these diverse sectors is not coincidental. It boasts a solid track record backed by scientific research, regulatory approvals, and substantial practical experience. Companies integrating silicon dioxide into their production processes can vouch for its enhanced performance metrics and customer satisfaction rates, attesting to its trustworthiness and indispensability as a component. Overall, whether in preserving the integrity of packaged foods, ensuring the efficacy of medications, or enhancing the durability of industrial products, silicon dioxide has positioned itself as a cornerstone additive. Its multi-faceted applications and the trust placed in it by different industries underscore its status as a critical, reliable, and innovative contributor to modern manufacturing processes.

In industrial applications, such as paints and coatings, silicon dioxide contributes significantly to the product's resilience. By improving the abrasion resistance and durability of coatings, it helps in extending the lifespan and maintaining the aesthetic properties of the surfaces applied. Automotive and construction industries rely on these attributes to provide long-lasting, visually appealing finishes, showcasing silicon dioxide's vital role in product enhancement. Furthermore, in the rubber industry, silicon dioxide is used as a reinforcing filler, enhancing the mechanical properties of rubber. Producers of automotive tires and industrial rubber products incorporate silicon dioxide to achieve superior performance, whether it be in terms of grip, longevity, or resistance to environmental factors. The adoption of silicon dioxide as an additive across these diverse sectors is not coincidental. It boasts a solid track record backed by scientific research, regulatory approvals, and substantial practical experience. Companies integrating silicon dioxide into their production processes can vouch for its enhanced performance metrics and customer satisfaction rates, attesting to its trustworthiness and indispensability as a component. Overall, whether in preserving the integrity of packaged foods, ensuring the efficacy of medications, or enhancing the durability of industrial products, silicon dioxide has positioned itself as a cornerstone additive. Its multi-faceted applications and the trust placed in it by different industries underscore its status as a critical, reliable, and innovative contributor to modern manufacturing processes.

Pervious