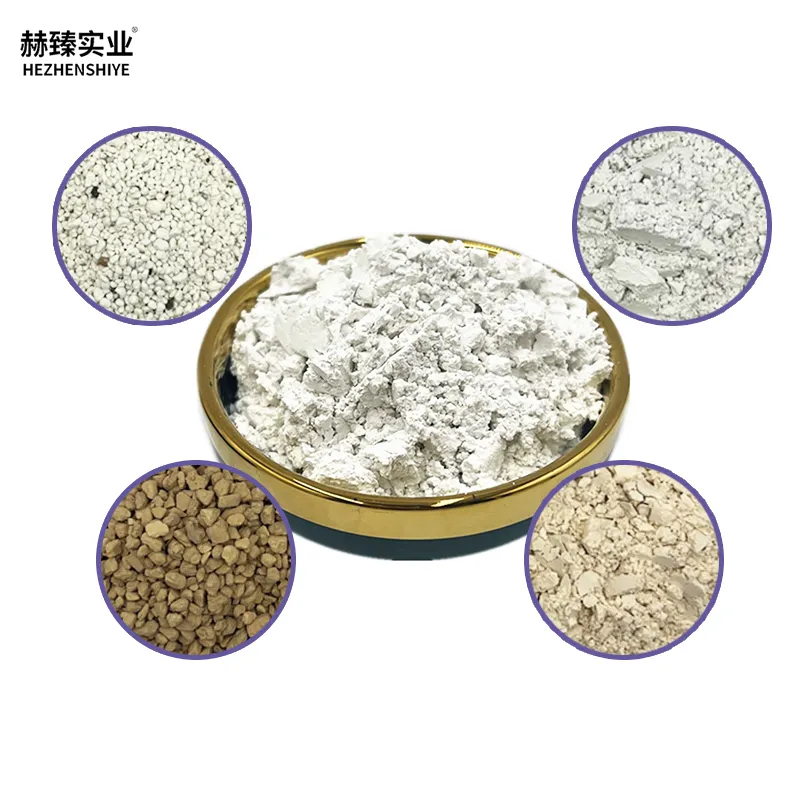

silicon dioxide cost

2025.01.12

Understanding the Cost Dynamics of Silicon Dioxide in the Market

Furthermore, geopolitical events can drive volatility in silicon dioxide costs. Trade policies, tariffs, and international relations can impact exchange rates and trade flows, directly affecting material costs. Recent global tensions have highlighted the importance of ensuring stable supply chains to mitigate drastic cost fluctuations. Trustworthy sourcing is another critical aspect. Manufacturers often prize consistent and reliable sources of silica, which can command a premium price. Certified suppliers that adhere to industry standards and environmental regulations assure businesses of product quality, justifying their cost structures. Industry knowledge and expertise further compound into how businesses react to cost changes. Companies well-versed in market trends and cost analysis can adeptly navigate price fluctuations by adjusting their procurement strategies. They might invest in bulk purchasing during low-price periods or diversify their sourcing contingencies to safeguard against supply chain disruptions. The future landscape of silicon dioxide costs will likely be shaped by sustainability practices and innovations. Eco-friendly extraction and processing techniques not only cater to environmental imperatives but potentially unlock cost efficiencies. Recycling and reusing silica from industrial byproducts could also emerge as economically viable options, fueling competitive pricing. In summary, the cost of silicon dioxide is an intricate tapestry woven from technology, demand, supply chain intricacies, and regulatory environments. Businesses aiming to harness the benefits of silicon dioxide must maintain an astute understanding of these dynamics, leveraging their expertise to align operational strategies with market movements for optimal economic outcomes. Such strategic insight not only bolsters a company’s bottom line but also fortifies its reputation as a resilient and forward-thinking player amidst fluctuating cost landscapes.

Furthermore, geopolitical events can drive volatility in silicon dioxide costs. Trade policies, tariffs, and international relations can impact exchange rates and trade flows, directly affecting material costs. Recent global tensions have highlighted the importance of ensuring stable supply chains to mitigate drastic cost fluctuations. Trustworthy sourcing is another critical aspect. Manufacturers often prize consistent and reliable sources of silica, which can command a premium price. Certified suppliers that adhere to industry standards and environmental regulations assure businesses of product quality, justifying their cost structures. Industry knowledge and expertise further compound into how businesses react to cost changes. Companies well-versed in market trends and cost analysis can adeptly navigate price fluctuations by adjusting their procurement strategies. They might invest in bulk purchasing during low-price periods or diversify their sourcing contingencies to safeguard against supply chain disruptions. The future landscape of silicon dioxide costs will likely be shaped by sustainability practices and innovations. Eco-friendly extraction and processing techniques not only cater to environmental imperatives but potentially unlock cost efficiencies. Recycling and reusing silica from industrial byproducts could also emerge as economically viable options, fueling competitive pricing. In summary, the cost of silicon dioxide is an intricate tapestry woven from technology, demand, supply chain intricacies, and regulatory environments. Businesses aiming to harness the benefits of silicon dioxide must maintain an astute understanding of these dynamics, leveraging their expertise to align operational strategies with market movements for optimal economic outcomes. Such strategic insight not only bolsters a company’s bottom line but also fortifies its reputation as a resilient and forward-thinking player amidst fluctuating cost landscapes.

Pervious

Next