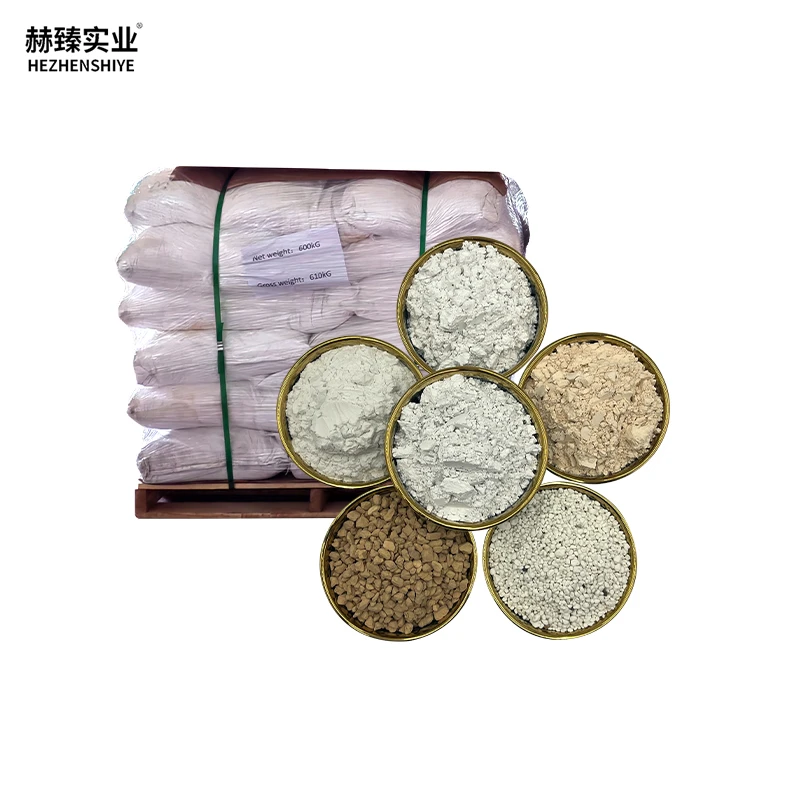

synthetic amorphous silica

2025.01.14

Synthetic amorphous silica (SAS) represents an essential and versatile product in various industrial applications. As a seasoned SEO strategist, let me shed light on the sophisticated nature of SAS and its impactful role across different sectors, ensuring this content not only ranks well but provides authoritative insights.

In the realm of cosmetics and pharmaceuticals, synthetic amorphous silica is celebrated for its ability to provide desired consistency and stability to formulations. Its oil-absorbing properties are leveraged in skincare products, ensuring formulas are non-greasy and effective. Pharmaceutical companies depend on SAS as a carrier for active ingredients and to enhance the stability of solid dosage forms. Trust in SAS's safety profile is solidified through extensive testing and regulatory compliance, thus reinforcing its credibility across healthcare applications. The environmental impact of SAS is another critical aspect highlighting its significance. As industries are increasingly held accountable for their footprints, the development and use of environmentally friendly products like synthetic amorphous silica are vital. Manufacturers are continuously optimizing production processes to ensure minimal environmental impact while maintaining high-quality output. This commitment to sustainability not only enhances the authority of SAS in the market but also aligns with global ecological goals, winning trust and confidence from stakeholders and consumers alike. Synthetic amorphous silica's versatility extends to its application in coatings, plastics, and adhesive products. The silica’s properties improve texture, enhance adhesion, and increase product lifespan, thereby offering value and efficiency to manufacturers and end-users. Expertise in precisely incorporating SAS into various formulations translates into innovation, differentiating brands in competitive markets. In summary, synthetic amorphous silica stands as a cornerstone ingredient across diverse industries, backed by extensive experience, scientific research, and authoritative endorsements. Its multifunctionality combined with a solid reputation for safety and sustainability, positions SAS not only as a product of choice but as a benchmark for quality and reliability. As industries evolve, synthetic amorphous silica will undoubtedly continue to inspire and elevate standards, fostering trust and loyalty among consumers and manufacturers globally.

In the realm of cosmetics and pharmaceuticals, synthetic amorphous silica is celebrated for its ability to provide desired consistency and stability to formulations. Its oil-absorbing properties are leveraged in skincare products, ensuring formulas are non-greasy and effective. Pharmaceutical companies depend on SAS as a carrier for active ingredients and to enhance the stability of solid dosage forms. Trust in SAS's safety profile is solidified through extensive testing and regulatory compliance, thus reinforcing its credibility across healthcare applications. The environmental impact of SAS is another critical aspect highlighting its significance. As industries are increasingly held accountable for their footprints, the development and use of environmentally friendly products like synthetic amorphous silica are vital. Manufacturers are continuously optimizing production processes to ensure minimal environmental impact while maintaining high-quality output. This commitment to sustainability not only enhances the authority of SAS in the market but also aligns with global ecological goals, winning trust and confidence from stakeholders and consumers alike. Synthetic amorphous silica's versatility extends to its application in coatings, plastics, and adhesive products. The silica’s properties improve texture, enhance adhesion, and increase product lifespan, thereby offering value and efficiency to manufacturers and end-users. Expertise in precisely incorporating SAS into various formulations translates into innovation, differentiating brands in competitive markets. In summary, synthetic amorphous silica stands as a cornerstone ingredient across diverse industries, backed by extensive experience, scientific research, and authoritative endorsements. Its multifunctionality combined with a solid reputation for safety and sustainability, positions SAS not only as a product of choice but as a benchmark for quality and reliability. As industries evolve, synthetic amorphous silica will undoubtedly continue to inspire and elevate standards, fostering trust and loyalty among consumers and manufacturers globally.

Pervious